High-horsepower tractor down-shift control method considering speed regulation characteristic of diesel engine

A technology of power downshifting and control methods, which is applied in the direction of transmission control, mechanical equipment, and components with teeth, etc., can solve the problems of transmission system component damage, diesel engine flameout, and large power loss, so as to avoid parking and downshifting. gears, reduce shifting time, and avoid parasitic power effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

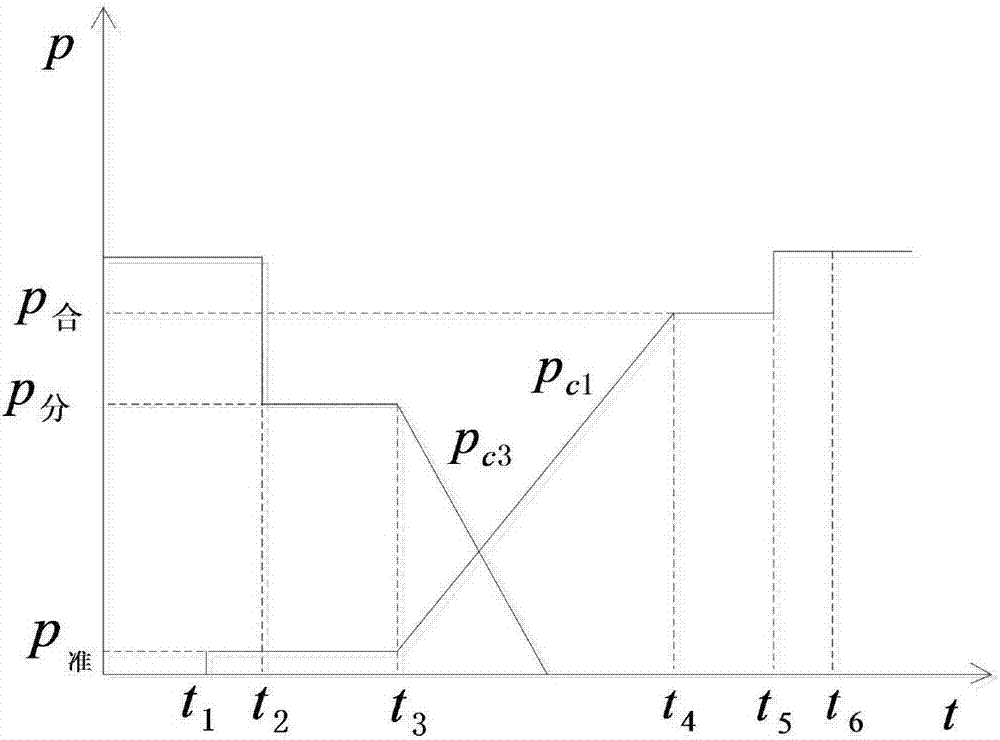

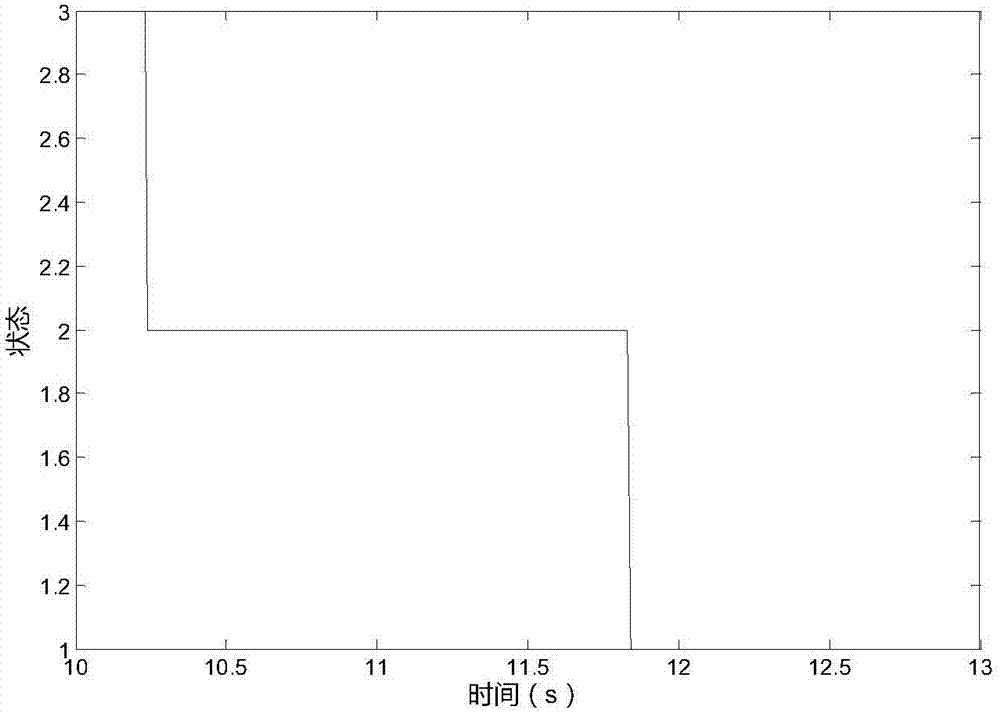

[0076] Embodiment: In this embodiment, the tractor upshift control method of the present invention is used to control the power shift transmission of a certain type of high-horsepower tractor from 4 gears to 3 gears.

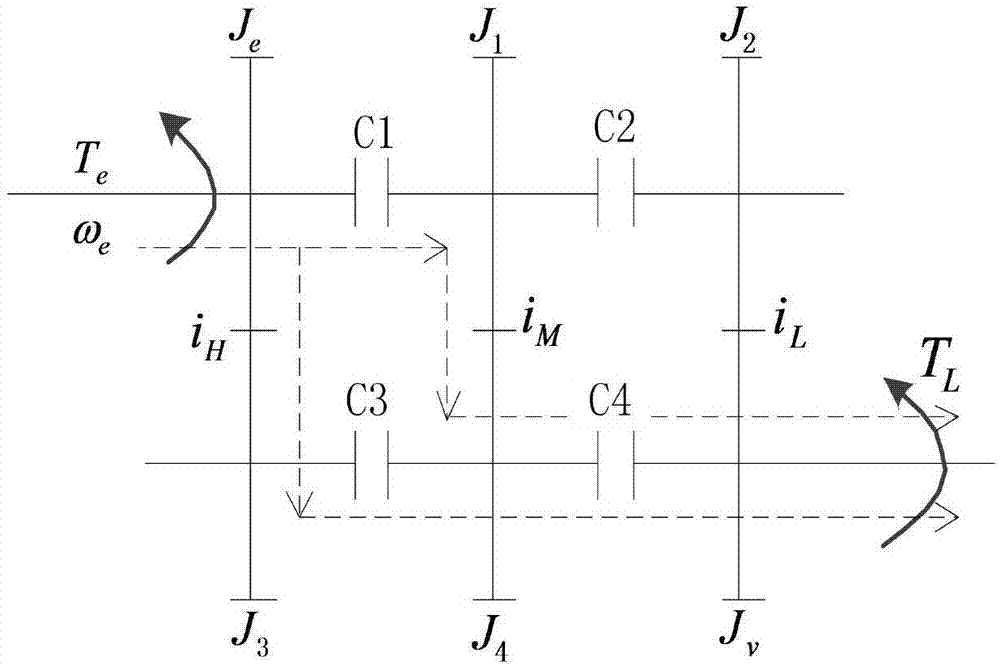

[0077] refer to figure 2 , C 1 、C 2 、C 3 and C 4 are shifting clutches respectively, when clutch C 1 、C 2 disengagement, clutch C 3 、C 4 When engaged, the gear of the power shift transmission is 4th gear; when clutch C 1 、C 4 Engage, clutch C 2 、C 3 When disengaged, the gear position of the power shift transmission is 3rd gear; when the gear position of the transmission is lowered from 4th gear to 3rd gear, the clutch C 1 From disengaged to engaged, clutch C 3 From engaged to disengaged, power flow gradually from clutch C 3 transition to clutch C 1 ;

[0078] The power system parameters of the high-horsepower tractor are as follows: the maximum torque transmitted by the clutch is 380N.m; the engine is a diesel engine with a rated power of 100kw, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com