Wind turbine generator gearbox fault monitoring method and system based on deep neural network

A deep neural network and wind turbine technology, applied in the field of wind turbine gearbox fault monitoring based on deep neural network, can solve the problems affecting the monitoring results, the influence of the surrounding environment and noise, etc., and achieve sensitive and high accuracy of process monitoring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a wind turbine gearbox fault monitoring method and system based on a deep neural network. The method and system can monitor gearbox faults in a timely and effective manner, and the monitoring results are less affected by the external environment and have high accuracy.

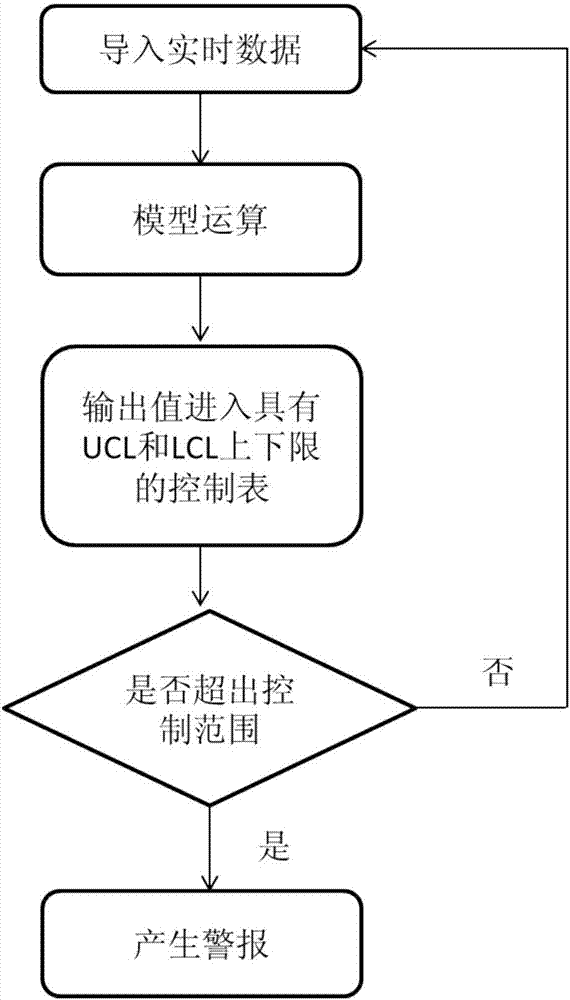

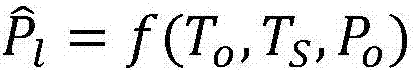

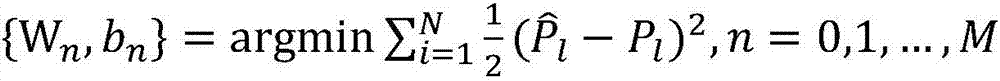

[0024] see figure 1 As shown, the gear box fault monitoring method of the present invention mainly includes the following steps: obtaining the relevant data of the gear box state in the SCADA real-time data of the wind turbine, including the gearbox lubricating oil pressure, the gearbox lubricating oil temperature, the gearbox bearing temperature and the unit Output power; input the gearbox lubricating oil temperature, gearbox bearing temperature and unit output power into the prediction model based on the deep neural network to obtain the predicted value of the gearbox lubricating oil pressure output by the prediction model; calculate the gearbox lubricating oil pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com