Electric-driven three-jaw chuck

A three-jaw chuck and electric drive technology, applied in the field of mechanical processing, can solve the problems of difficult realization and control of lathe automation, and achieve the effect of simple structure, strong practicability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

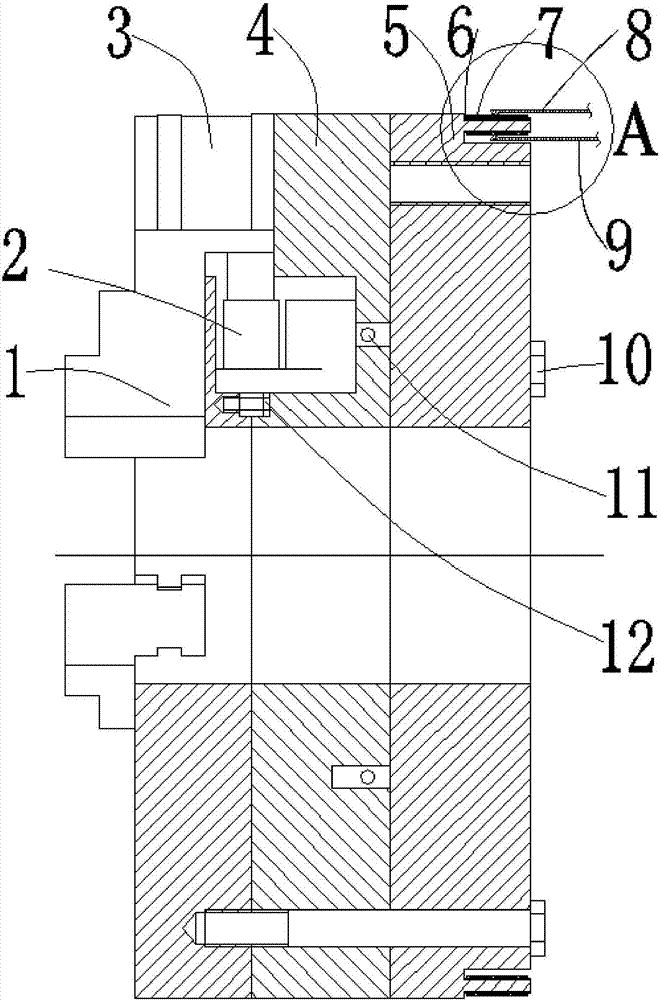

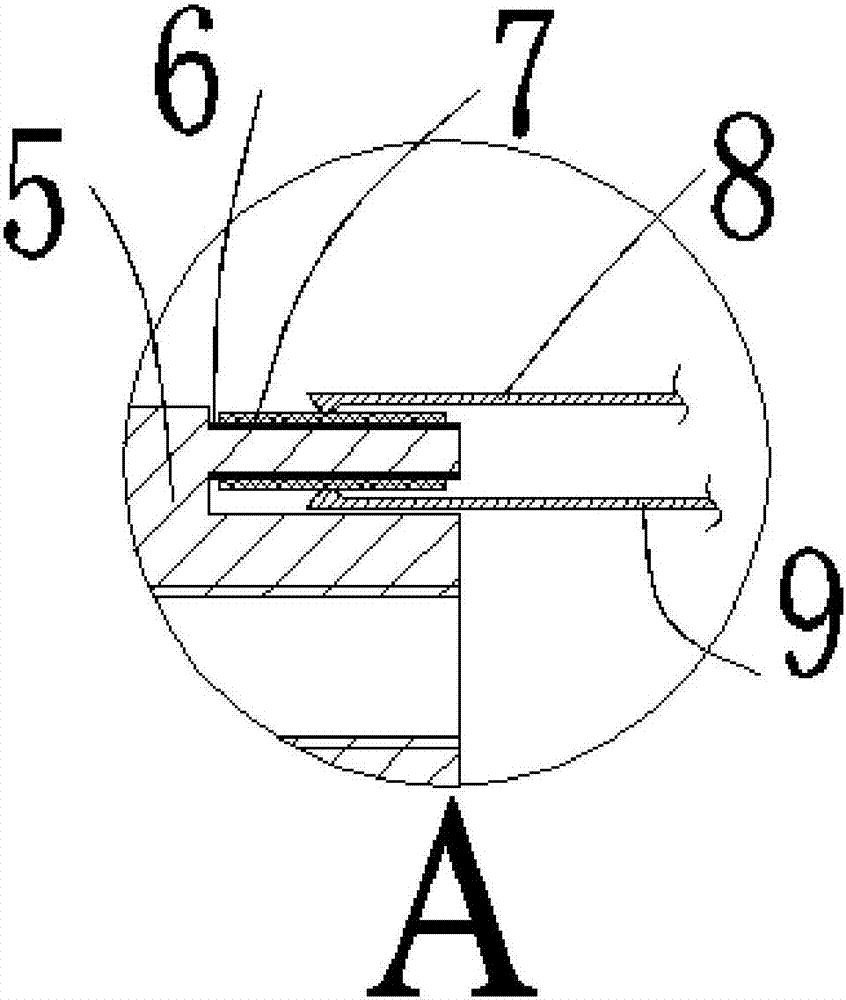

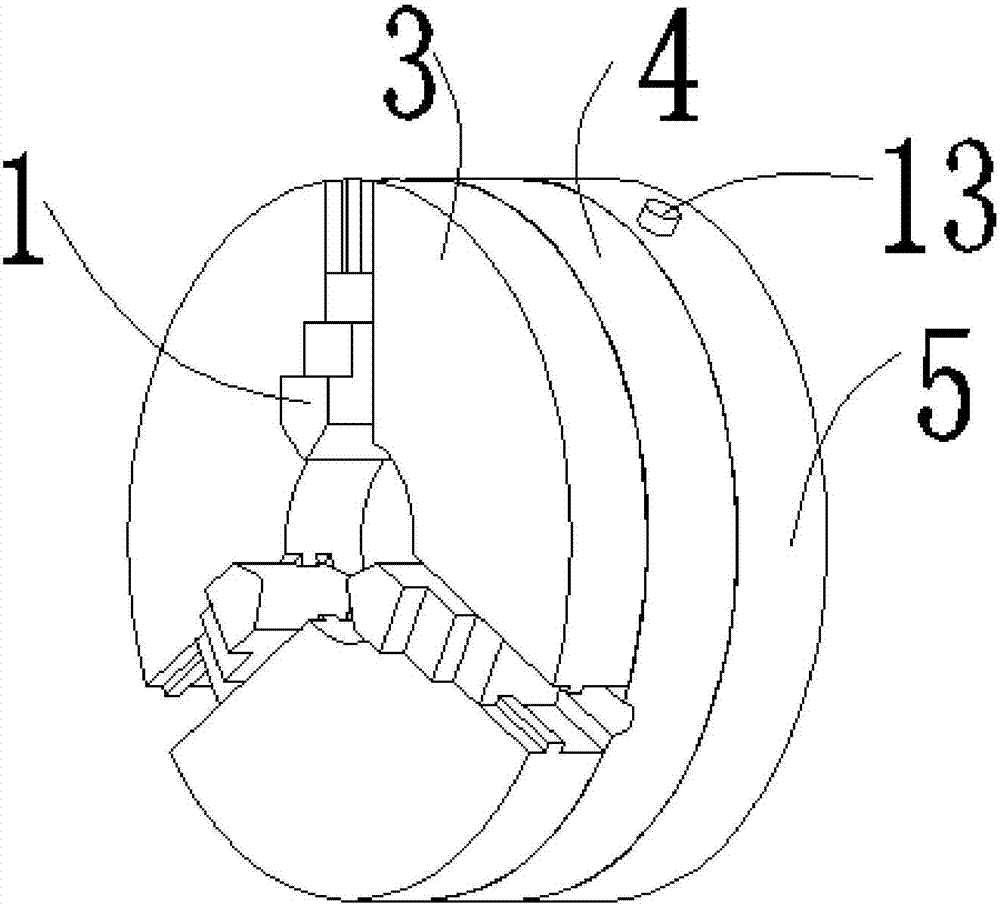

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 The present invention described in the shown invention discloses an electrically driven three-jaw chuck, comprising jaws 1, electric cylinder 2, front chuck 3, middle chuck 4, rear chuck 5, insulating ring 6, slide Ring 7, positive electrode brush 8, negative electrode brush 9, bolt I10, wire 11, bolt II12, switch 13 and balance pin 14, characterized in that: the claws 1 are arrayed axially along the left end of the front chuck 3, and The movable pair is connected between the jaw 1 and the front chuck 3, the upper end of the jaw 1 is provided with a jaw baffle 101, the two sides of the jaw 1 are provided with a rectangular groove 102; the center of the front chuck 3 is provided with a through hole I302, one side of the front chuck 3 has three I-shaped guide rail grooves 301 in an axial array along the outer circle of the through hole I3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com