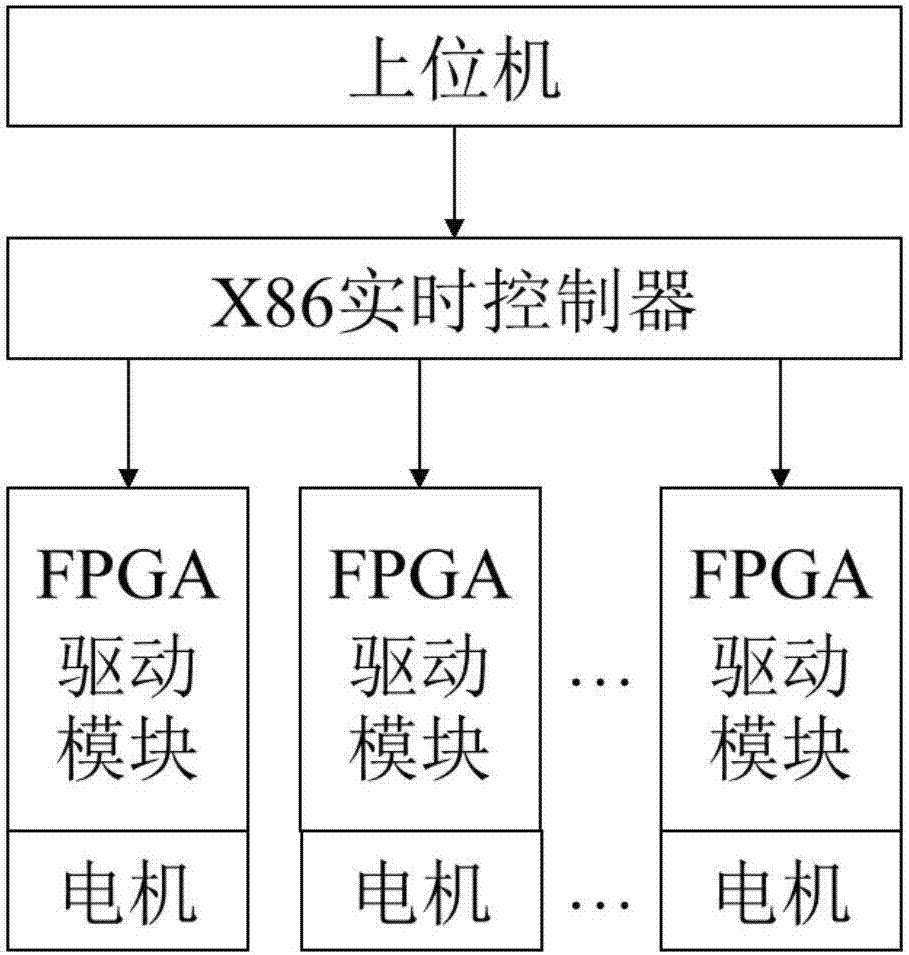

Driving and control integrated control system used for collaborative robot

A control system and robot technology, applied in the direction of program control manipulators, instruments, manipulators, etc., can solve the problems that signal transmission is susceptible to interference, limits the real-time and rapidity of industrial robots, and is expensive, so as to achieve the effect of promoting use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

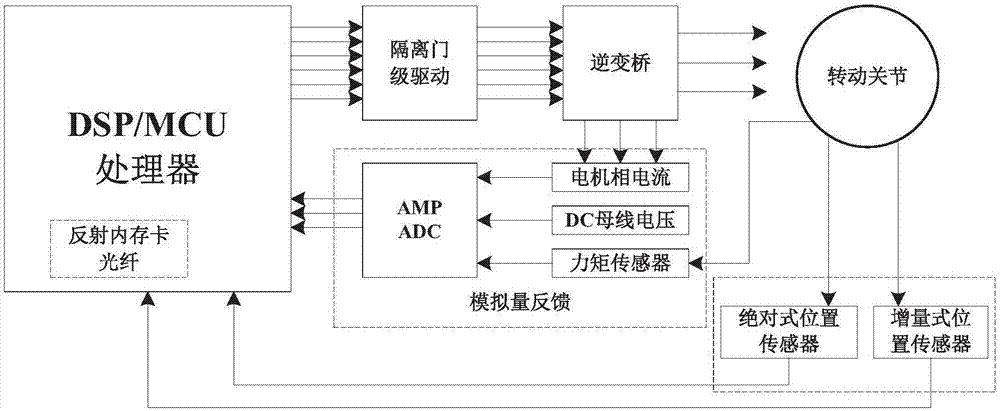

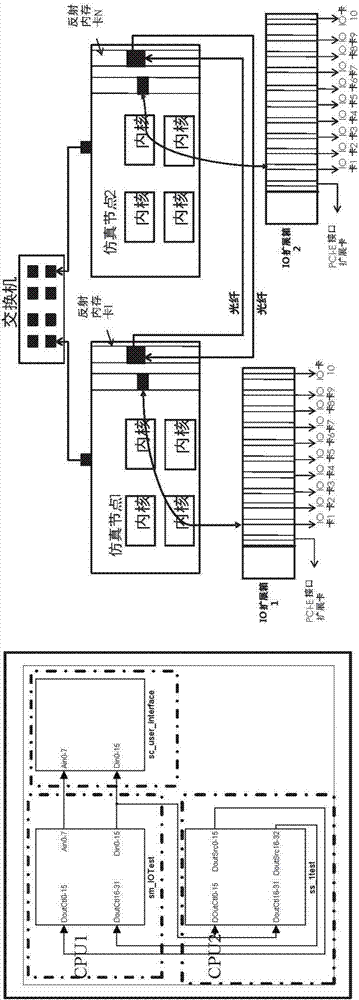

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer and clearer, the present invention will be described in further detail below with reference to the accompanying drawings and examples, but the present invention is not limited to these examples.

[0038] Said FPGA (Field-Programmable Gate Array) of the present invention, namely Field Programmable Gate Array, it is the product of further development on the basis of programmable devices such as PAL, GAL, CPLD. It emerged as a semi-custom circuit in the field of application-specific integrated circuits (ASIC), which not only solves the shortcomings of custom circuits, but also overcomes the shortcomings of the limited number of original programmable device gates.

[0039] The circuit design completed in hardware description language (Verilog or VHDL) can be quickly burned to FPGA for testing after simple synthesis and layout, which is the mainstream of modern IC design verificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com