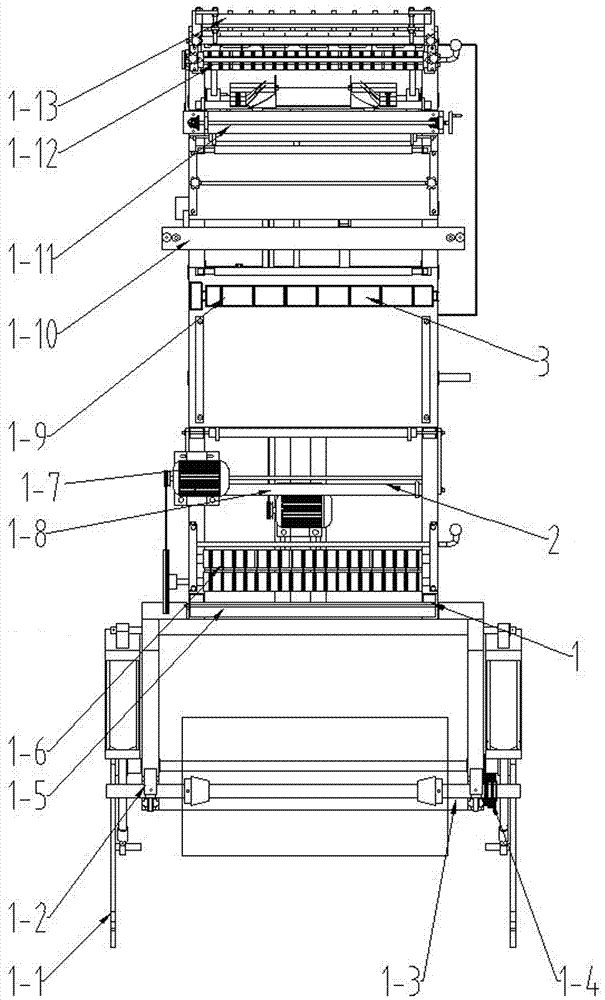

Inner film bag making machine and multi-station device

A multi-station, bag-making machine technology, which is applied in bag-making operations, packaging, transportation and packaging, etc., can solve the problems of single-station, low production efficiency, and labor shortage of inner film bag-making machines, and improve the quality of weighing , Improve production efficiency, optimize the effect of functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

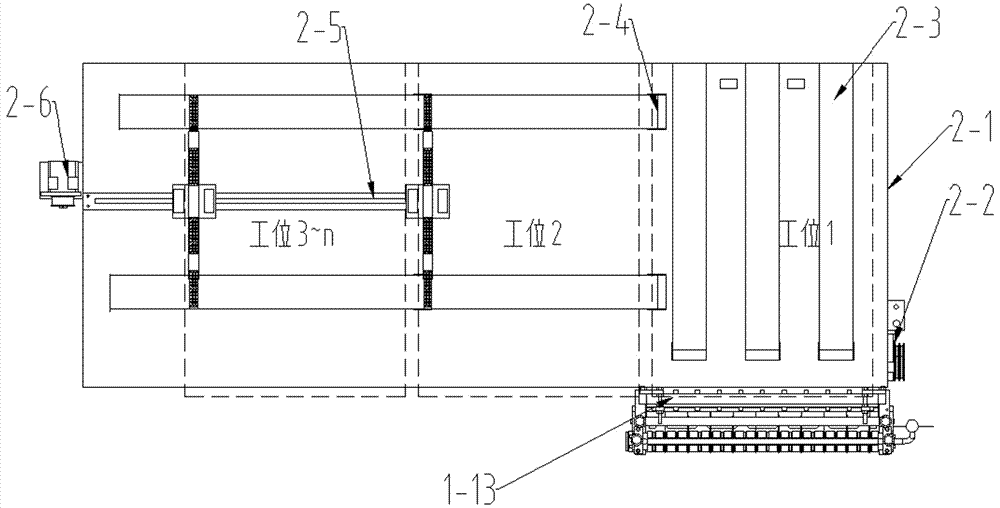

[0020] The multi-station device includes a support 2-1, on which a belt 2-3 driven by a belt conveying mechanism 2-2 is installed, and on the support 2-1, a conveying device 2 Transverse conveying fixture 2-4 on -5, after the inner film bag is conveyed in such as figure 2 The position of station 1 shown is driven by the belt 2-3 to transport and position the inner membrane bag, and the error of the bag length does not exceed ±1mm. Under the traction of the conveying device 2-5, the inner film bag, the horizontal conveying fixture 2-4 is controlled by the forward or reverse pulse of the servo motor 2-6, and moves to the second station to the left, at this time the inner film bag is again Conveying out, the same method as before, can be driven and controlled by the servo motor again, and continue to move to the left to form three or more stations. In the next step, the horizontal conveying fixture 2-4 is a rubber suction cup fixture or a stainless steel row seat suction cup fi...

Embodiment 2

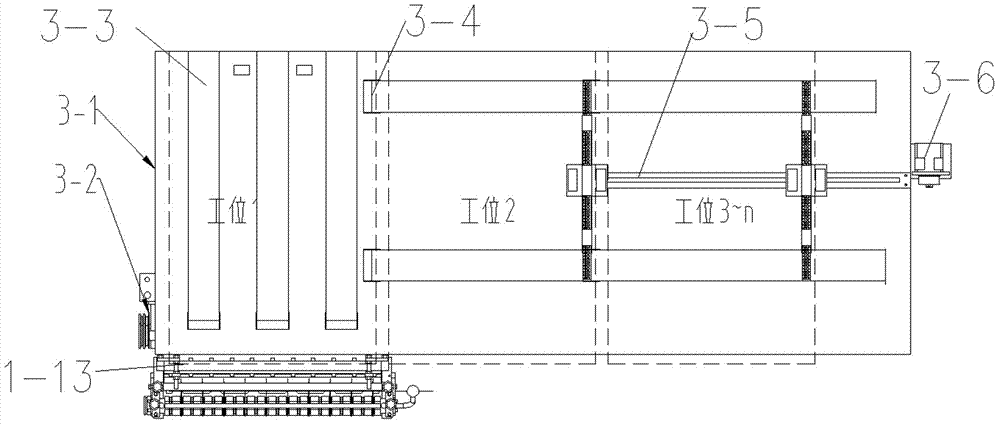

[0022] The multi-station device of the present invention includes a second support 3-1, on which a second belt 3-3 driven by a second belt conveying mechanism 3-2 is installed, and on the second support 3-1, The support 3-1 is also provided with a second lateral delivery fixture 3-4 on the second delivery device 3-5, after the inner film bag is delivered figure 2 The position of the middle station 1 is driven by the second belt 3-3 to transport and position the inner membrane bag. The error of the bag length does not exceed ±1mm. -4 clamps the intima bag, and the second lateral conveying fixture 3-4 is pulled by the second conveying device 3-5, controlled by the forward or reverse pulse of the second servo motor 3-6, and moves to the right to the second The second station, at this time, the inner membrane bag is conveyed out again, the same as the previous method, which can be driven and controlled by the servo motor again, and continues to move to the right to form the inner...

Embodiment 3

[0024] The multi-station device of the present invention includes a third support 4-1, on which a third belt 4-3 driven by a third belt conveying mechanism 4-2 is installed, and on the third support 4-1, The left side of the belt 4-3 is provided with a left transverse conveying fixture 4-4 on the third conveying device 4-5, and a right transverse conveying fixture 4-7 is arranged on the right side of the third belt 4-3. After the film bag is transported in such as Figure 4 The position of the station 2, after conveying and cutting, the left lateral conveying jig 4-4 installed on the third support 4-1 clamps the inner membrane bag, and the left lateral conveying jig 4-4 is at the bottom of the third conveying device 4 -5 traction, controlled by the forward or reverse pulse of the servo motor 4-6, first move to the left to the third station, at this time the inner film bag is transported out again, and as it moves to the left, the right horizontal conveying fixture 4- 7. G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com