Double-lip distortion resistance air inlet duct structure suitable for crosswind working condition

An anti-distortion, air inlet technology, which is applied to the combustion of the air inlet of the power unit, the arrangement/installation of the power unit, aircraft parts, etc., can solve the problems of lack of practical value, energy loss, etc., and achieve stable air flow and smooth air flow. Effect of Distortion Strength Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

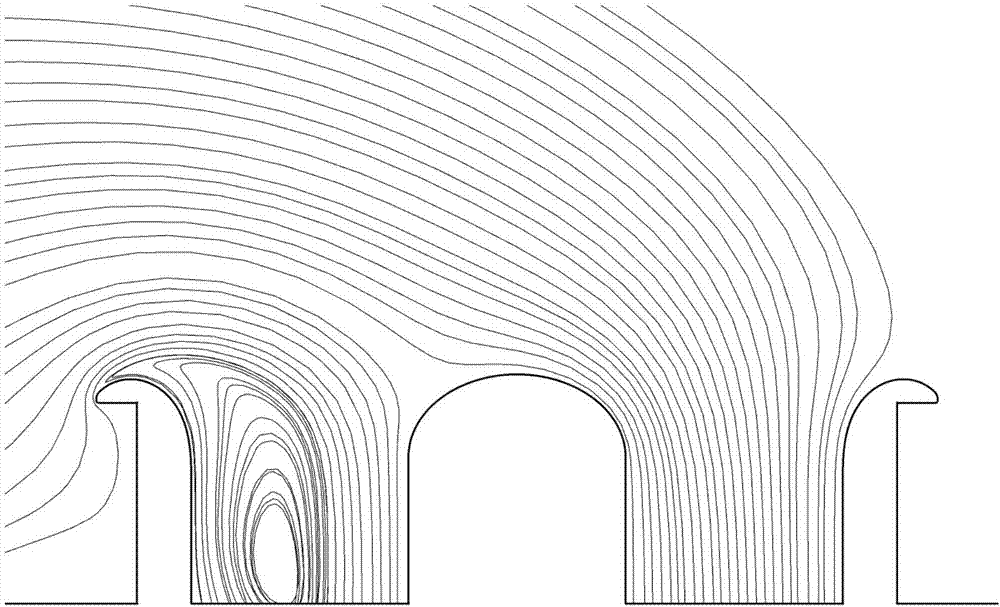

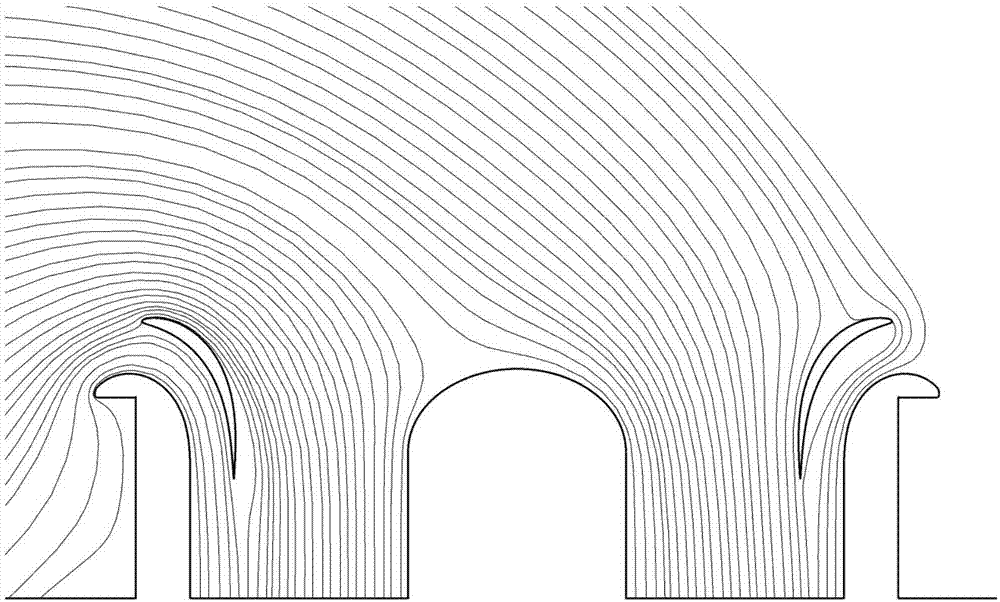

[0026] 1. See Figure 1-Figure 2 , the present invention is aimed at the power system of the existing vertical take-off and landing aircraft, which is prone to lip airflow separation phenomenon in the crosswind condition and the gust condition, resulting in the performance degradation of the aircraft or even loss of control, while the existing improvement measures are less achievable, and propose The double-lip anti-distortion inlet is suitable for cross-wind conditions. When the traditional inlet encounters cross-wind, flow separation is easily generated on the windward side of the lip, resulting in flow field distortion, such as figure 1 shown. The present invention obviously suppresses this separation phenomenon, the air flow is stable, and the air flow distortion intensity is obviously reduced, as seen figure 2 shown.

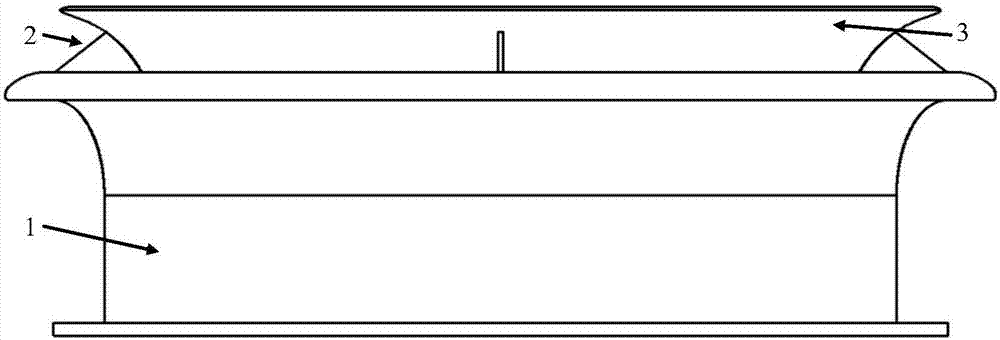

[0027] 2. See Figure 3-Figure 7 , the double-lip anti-distortion air inlet structure of the present invention is suitable for cross-wind conditions, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com