Three-dimensional plate material warehouse

A board and three-dimensional technology, which is applied in the field of three-dimensional material warehouses for boards, can solve the problems of easily damaged sliding connection parts, low space utilization rate, and inability to balance, and achieve the effects of stable structure, high space utilization rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

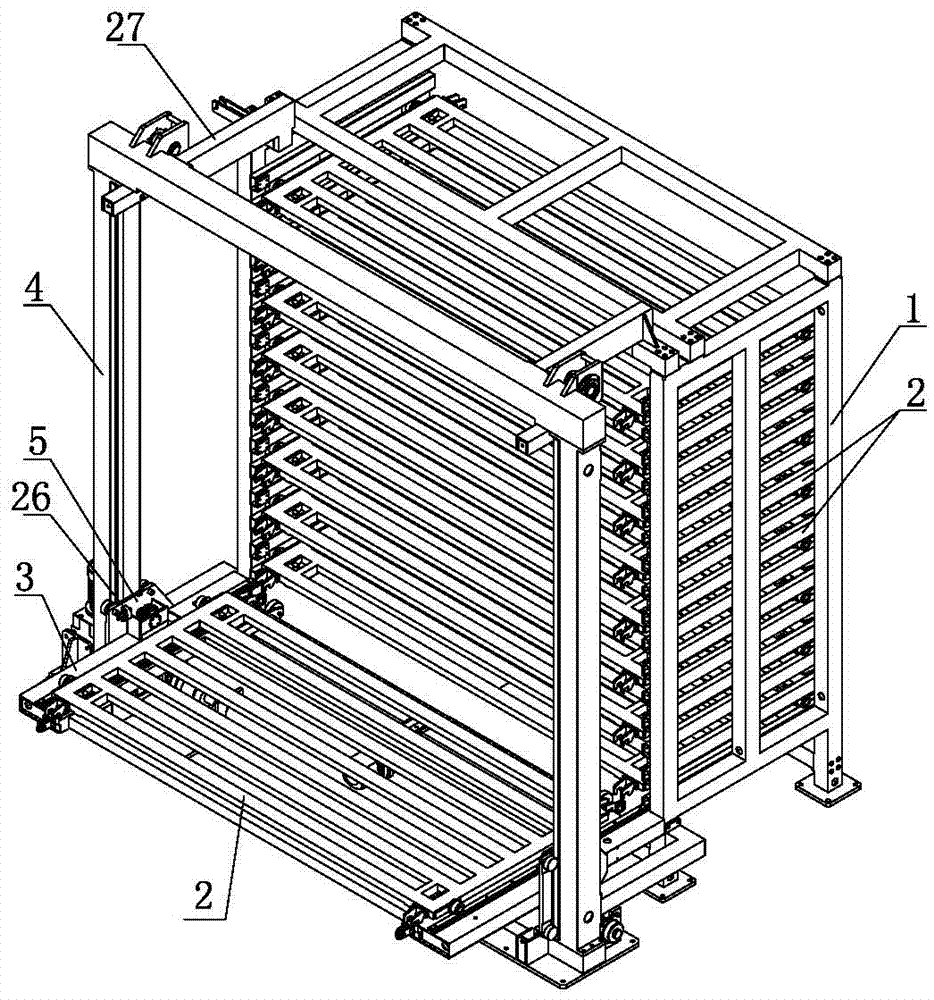

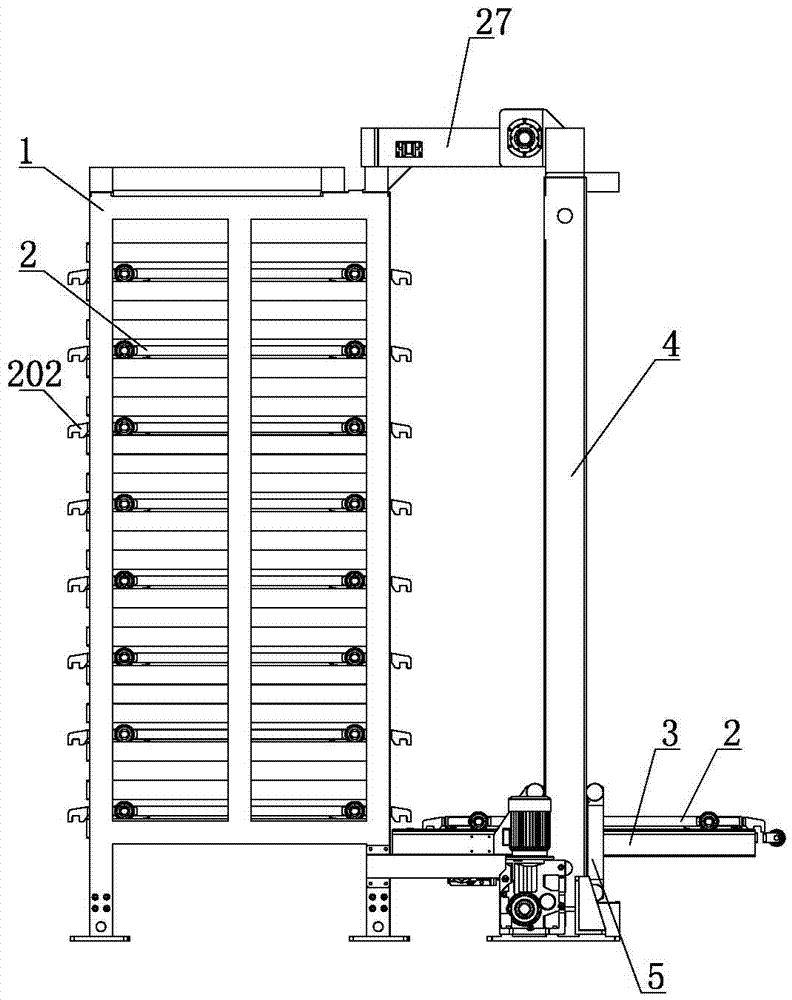

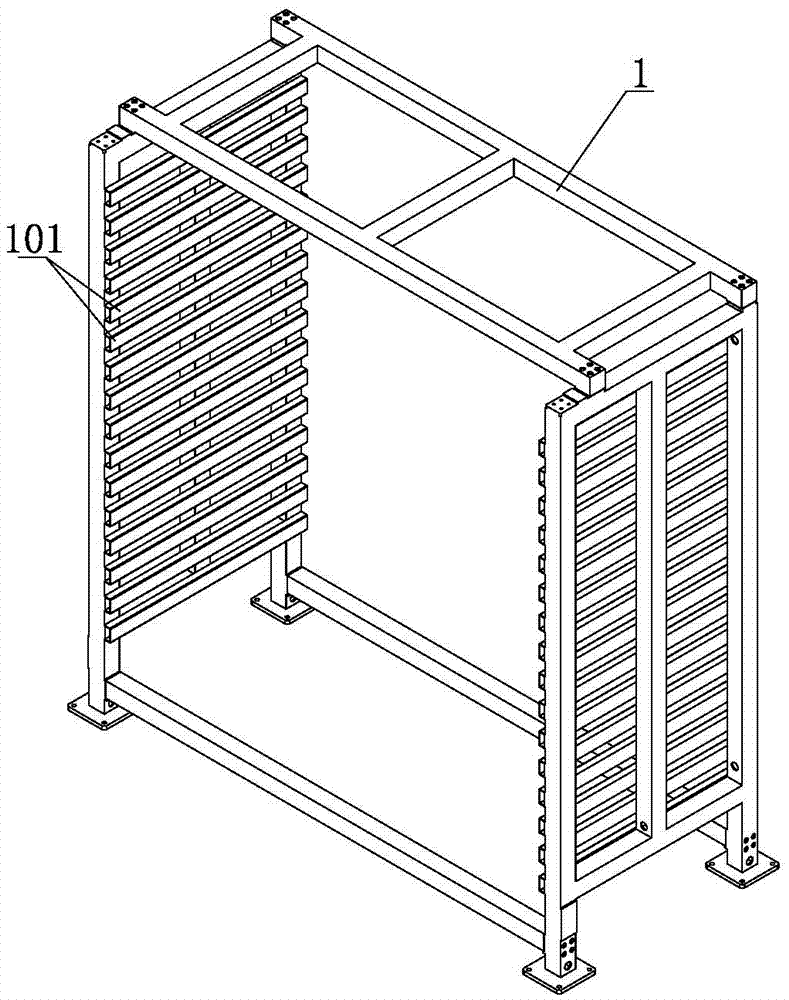

[0035] Such as Figure 1-17 , is a three-dimensional material warehouse for plates, including a plate storage rack 1, and the plate storage rack 1 is provided with several groups of feeder guide rails 101 at intervals from top to bottom, and the feeder guide rails 101 are matched with the wheels 201 of the mobile feeder 2 Setting, the mobile material trolley 2 is placed on the lifting base 3, the lifting base 3 is provided with a material trolley guide rail 2 301 matched with the wheel 201, and the lifting base 3 is also provided with a traction mechanism for pulling the mobile material vehicle 2 into and out of the plate storage rack 1 Mechanism, the front of the plate storage rack 1 is correspondingly provided with a gantry guide frame 4, the lifting seat 3 is located between the left and right columns 4a of the gantry guide frame 4, and the left and right sides of the lifting seat 3 are provided with guide seats 5, guiding The seat 5 is provided with at least two pairs of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com