Cement wall face leveling device for building

A kind of construction and cement technology, which is applied in the direction of construction and building construction, etc., can solve the problems of high cost, wear and tear, easy to wear blade blades, etc., and achieve the effect of improving quality, long service life and avoiding local damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

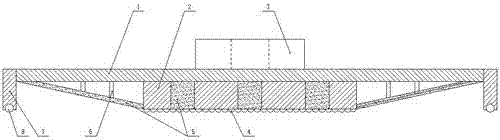

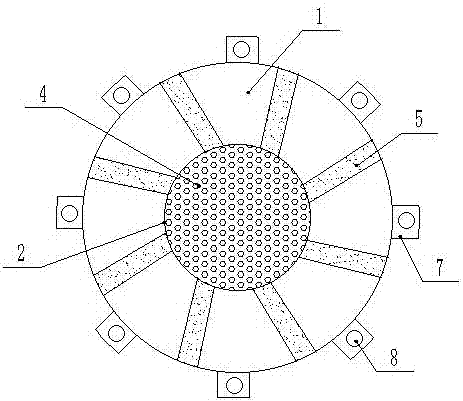

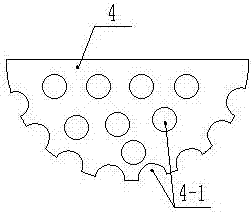

[0017] Such as Figure 1-Figure 3 As shown, a cement wall smoothing device for construction includes a top plate 1, the top plate 1 is a circular plate, the top center is fixed with a connecting piece 3 for connecting with the driving device, and the bottom center of the top plate 1 is fixed with a A circular friction plate 2, the bottom of the circular friction plate 2 is provided with a plurality of wear-resistant particles 4 integrated with it, and the wear-resistant particles 4 are formed by opening a plurality of concave holes 4-1 on the semicircular particles The edge of the circular friction plate 2 is symmetrically provided with a plurality of blades 5, the two ends of the blades 5 are respectively fixed to the bottom of the top plate 1 and the lower end of the edge of the circular friction plate 2, and the blade surface of the blade 5 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap