Circulating system and method for lubricating oil of steam turbine

A circulatory system and lubricating oil technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of long time for maintenance and trial operation of steam turbines, shortening the time of maintenance and trial operation, and low efficiency of oil circulation process. , to shorten the time of maintenance and trial operation, improve the utilization rate of equipment, and improve the effect of traditional oil circulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

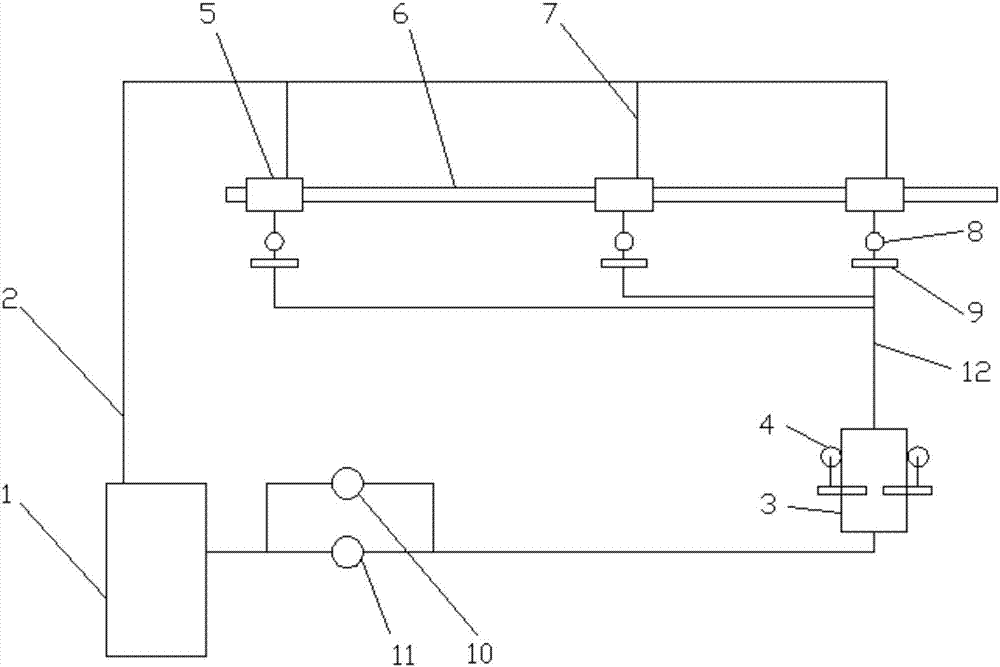

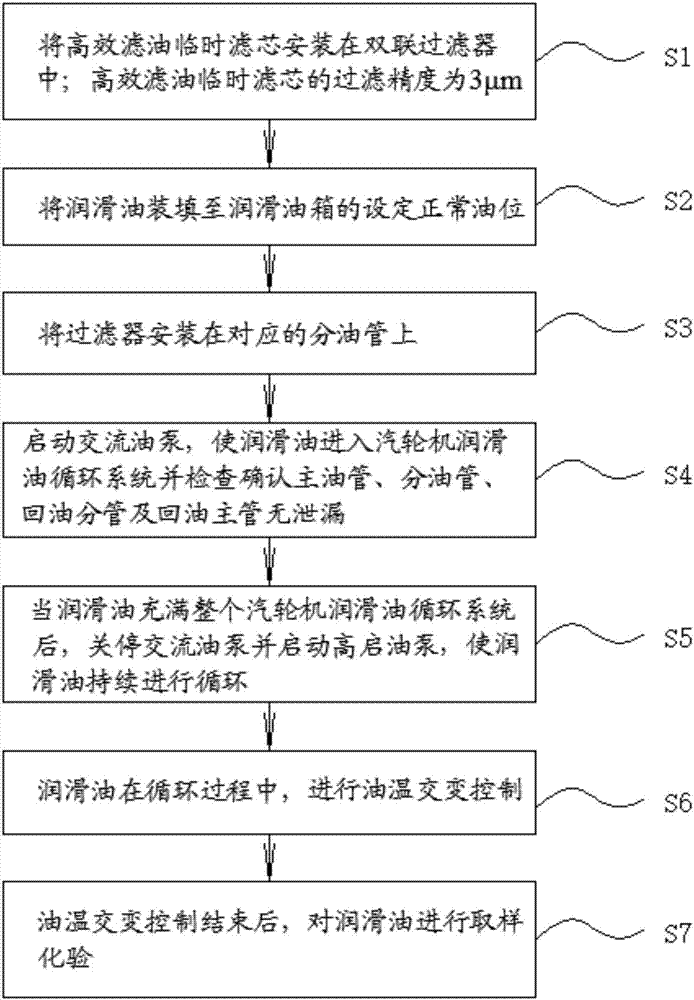

[0050] The embodiment of the present application provides a steam turbine lubricating oil circulation system and method, which solves or partially solves the technical problem that the efficiency of the oil circulation process in the prior art is low, which leads to a long time for steam turbine maintenance and trial operation. The high-efficiency oil filter temporary filter element with a precision of 3 μm is installed in the double filter, and the filter is installed on the corresponding oil distribution pipe, and the lubricating oil is continuously circulated through the high-start oil pump; during the circulation process, the oil temperature of the lubricating oil is controlled The alternating control realizes the technical effect of improving the traditional oil circulation process, improving the oil circulation efficiency of the steam turbine, and shortening the time for maintenance and trial operation.

[0051] A steam turbine lubricating oil circulation system provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com