Slurry pump piston

A mud pump and piston technology, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of inability to convert and adjust, fixed slurry discharge volume, and small application range, so as to save equipment purchase expenses, Wide application range and strong universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

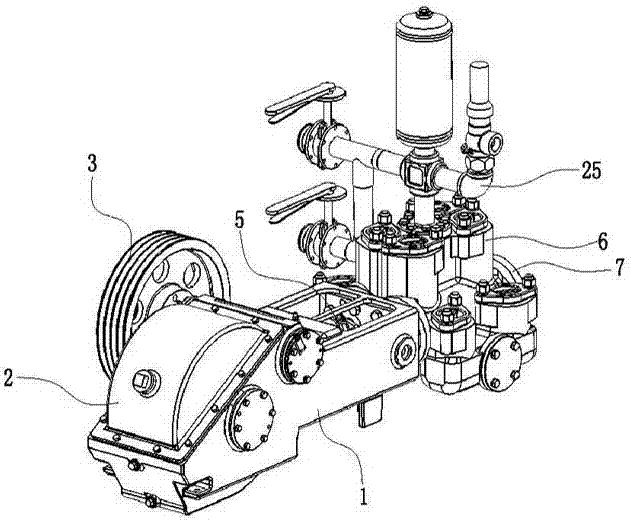

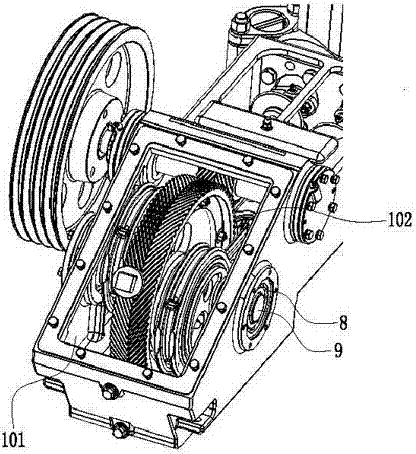

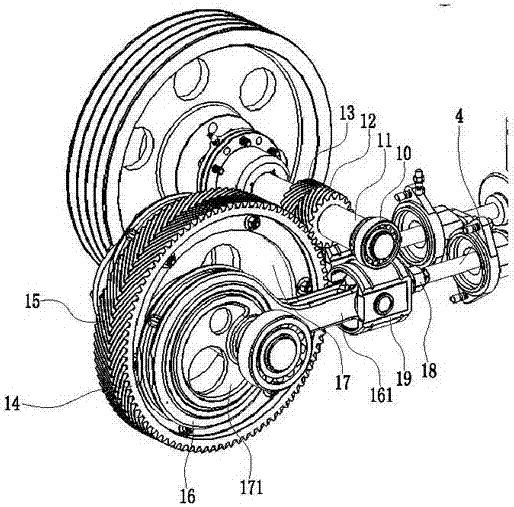

[0020] Such as Figure 1~6 As shown, a mud pump piston includes a piston 19, a conversion block 20, a sealing strip 21, and a connecting assembly; the connecting assembly includes a connecting shaft 22, a clamp ring 24 and a sleeve 23. The rear end of the piston chamber 1 and the slurry discharge mechanism 6 Connected, the back side of the slurry mechanism 6 is equipped with a slurry pipe seat 7, the slurry pipe seat 7 is connected with a pipe, and the slurry mechanism 6 is equipped with an air pressure regulating mechanism 25; the upper front end of the piston chamber 1 is provided There is a transmission cavity 101, and a protective cover 2 is fixed on the outside of the opening of the transmission cavity 101, which is convenient for maintenance and oil filling and has a good protective effect; two symmetrically distributed inner walls are respectively fixed on the left and right sides of the transmission cavity 101 A first bearing 8 and two symmetrically distributed second b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com