Self-adaption high-precision bearing end surface fixed part

A high-precision, self-adaptive technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reducing the service life of bearings, the difficulty of ensuring the perpendicularity between the end face of the end face fixing nut and the thread, and processing errors, etc., to achieve reliable fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

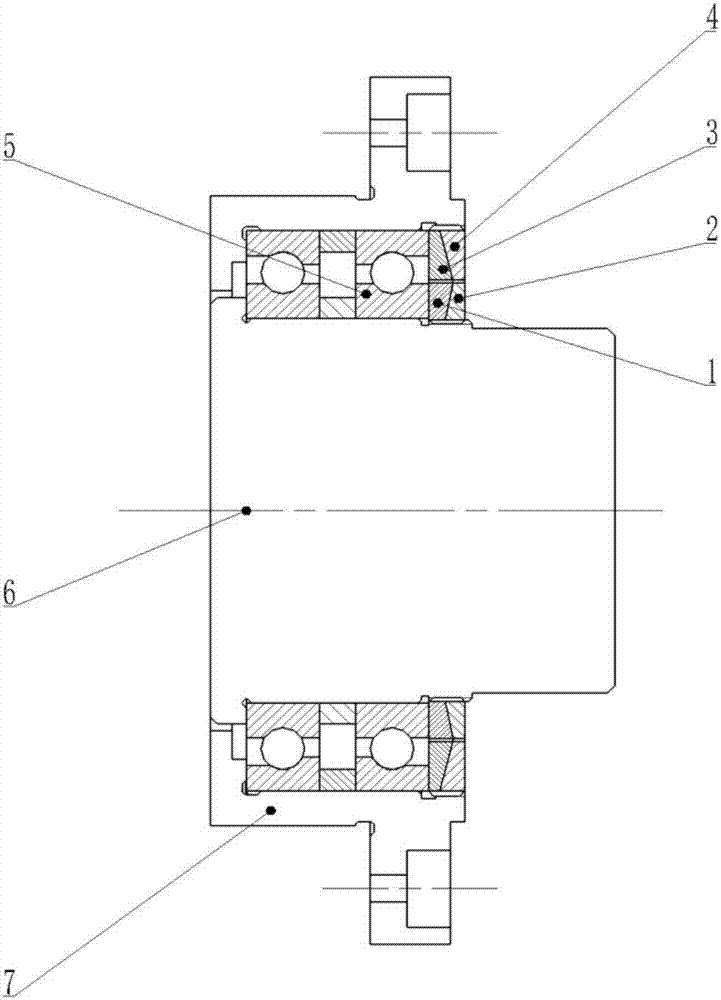

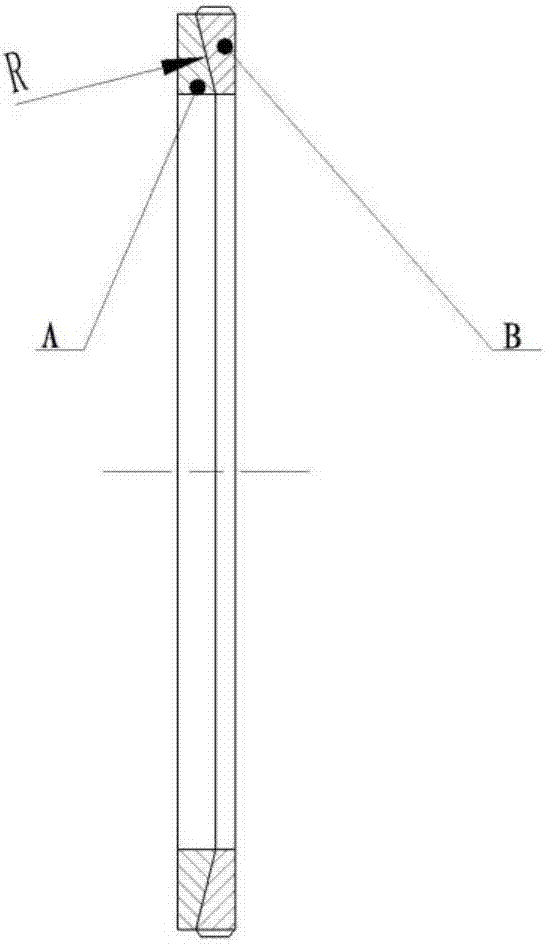

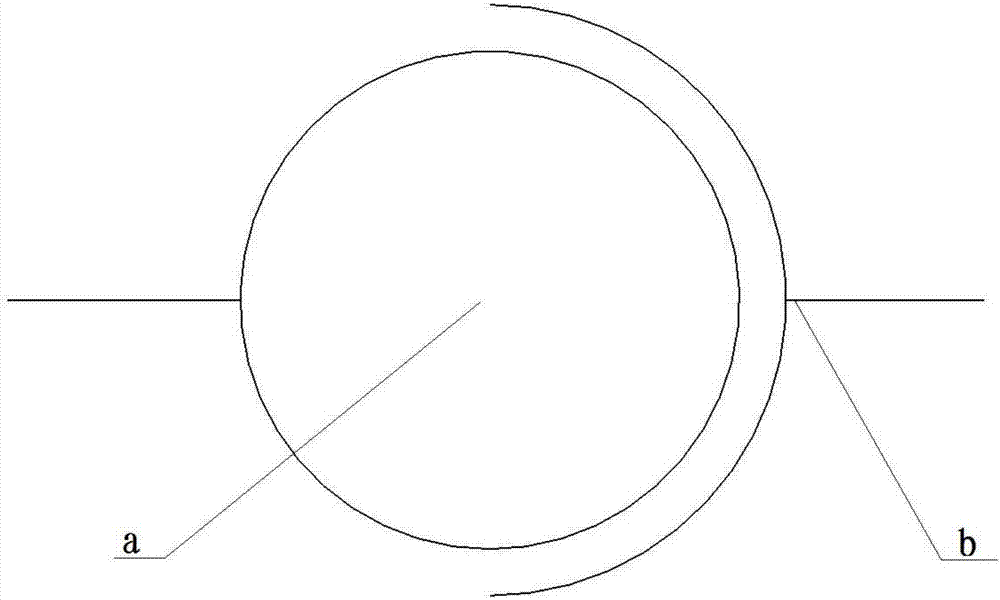

[0016] Attached below figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , to further illustrate the present invention, concrete design is as follows:

[0017] 1) Fixed parts on the end face of the bearing outer ring

[0018] The fixed parts of the end face of the bearing outer ring include the spherical retaining ring of the bearing outer ring and the lock nut of the bearing outer ring. The inner and outer circles of the spherical retaining ring of the bearing outer ring have no threads, and there is a gap of about 0.1mm with the bearing seat. One end face is flat, and the other end face is a convex spherical surface with radius R. The inner circle of the lock nut of the bearing outer ring has no thread, and the outer circle has thread. One end face is flat, and the other end face is a concave spherical surface with radius R. The spherical retaining ring of the bearing outer ring and the lock nut of the bearing outer ring form a spherical pair, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com