Warm forging die guide structure with upward ramming function

A die-guided, warm forging technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. Conflict with the guide structure and other problems, to achieve the effect of improving production efficiency, ensuring the quality requirements of forgings, and ensuring the runout accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

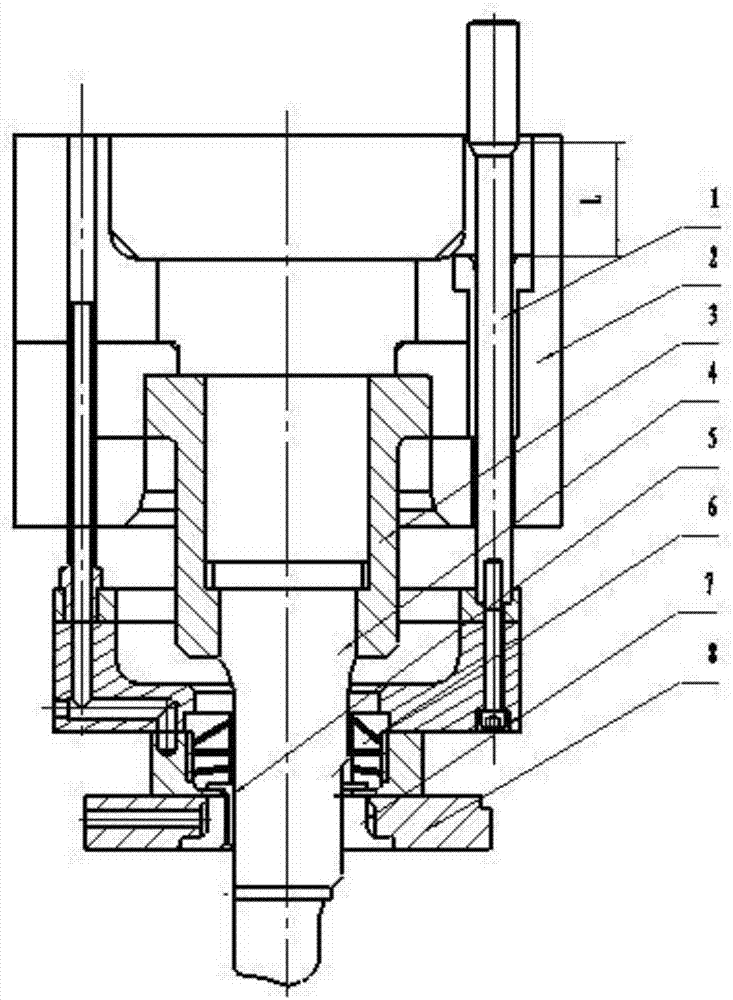

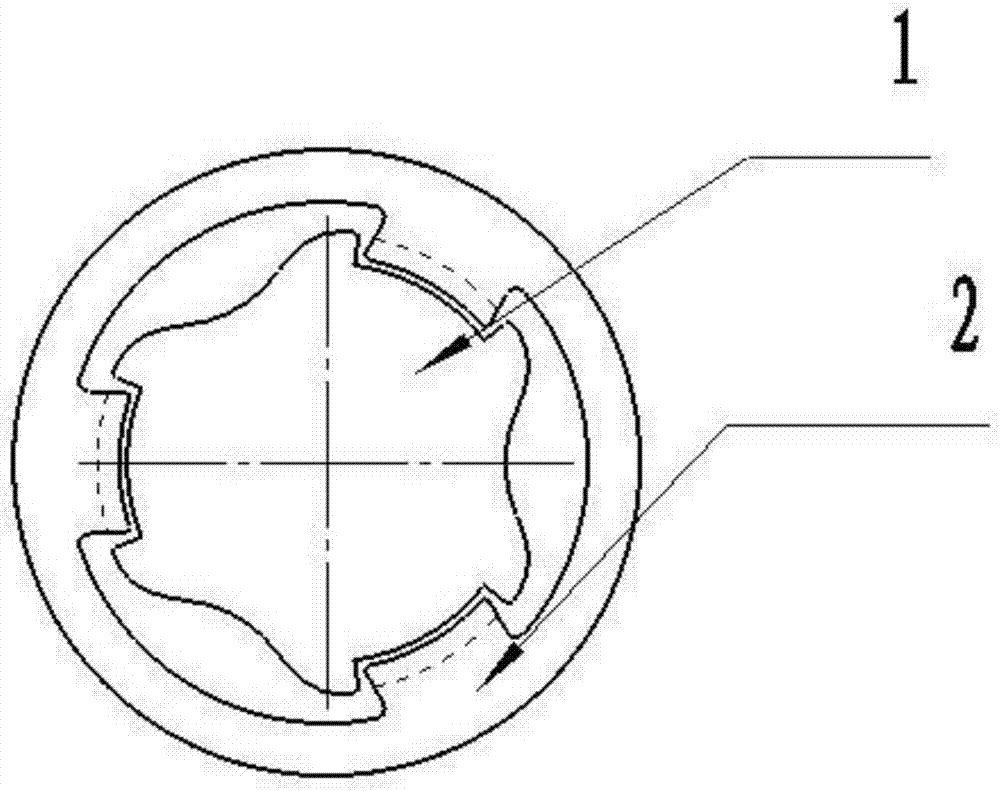

[0017] figure 1 and figure 2 It schematically shows the guiding structure of the warm forging die with topping material according to an embodiment of the present invention. Such as figure 1 and figure 2 As shown, the guide structure of the warm forging die with upper material injection includes an upper mold base 2, a lower mold base 8 and a spray material injection assembly.

[0018] The upper die base 2 is provided with a reverse extrusion punch 4 and a cavity for accommodating the punching rod 1 . Specifically, the reverse extrusion punch 4 is fixedly connected to the upper die base 2 through the punch sleeve 3 . Make the reverse extrusion punch 4 and the upper die base 2 firmly connected. The punching rod 1 includes a first rod body and a second rod body. The diameter of the first rod body is larger than the diameter of the second rod body. The punching rod 1 is arranged in parallel with the reverse extrusion punch 4 . It is convenient for the up and down movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com