Novel special speed reducer for boring machine

A technology of reducer and boring row, which is applied in the field of new-type special reducer for boring and rowing, which can solve the problems of difficult processing of worm gears, easy wear of worm gears, inconvenient installation, etc., to reduce labor consumption and maintenance costs, ensure ellipticity, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

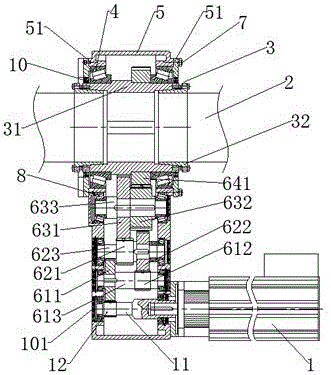

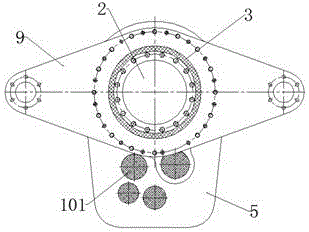

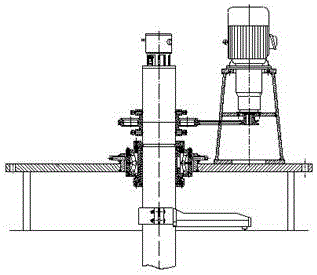

[0031] Such as figure 1 with 2 As shown, a new type of special reducer for boring and arranging, including motor (1), main shaft (2), bearing sleeve (3), first bearing (4) and The casing (5), and the transmission mechanism (6) arranged in the casing (5). The present invention adopts a compact integral layout, which reduces the assembly time of the boring row.

[0032] Among them, the bearing sleeve (3) includes the main shaft sleeve (31) and the inner sleeve (32) respectively arranged on the inside of both ends of the main shaft sleeve (31). The inner sleeve (32) is provided with a taper, and the outer surface of the inner sleeve (32) is Tapered surface, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com