Oil replenishment-discharge piston structure with floating valve plates, and use method thereof

An oil piston and suspension technology, applied in the direction of springs, shock absorbers, spring/shock absorbers, etc., can solve the problems of easy deformation and damage of the valve plate, achieve rapid oil replenishment, ensure service life, and solve the problem of easy deformation and damage damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

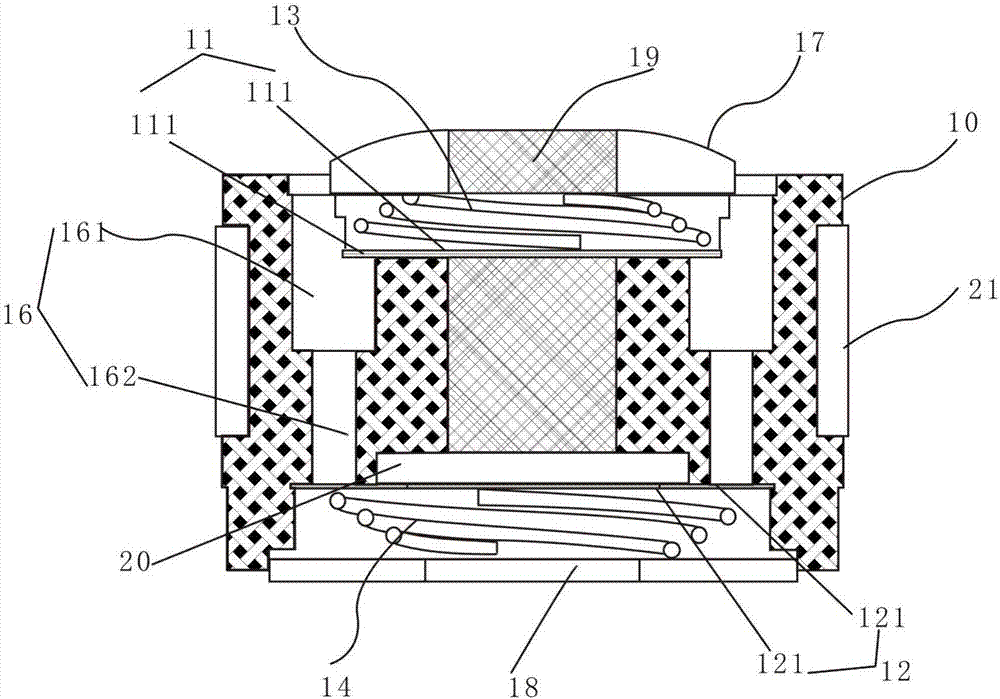

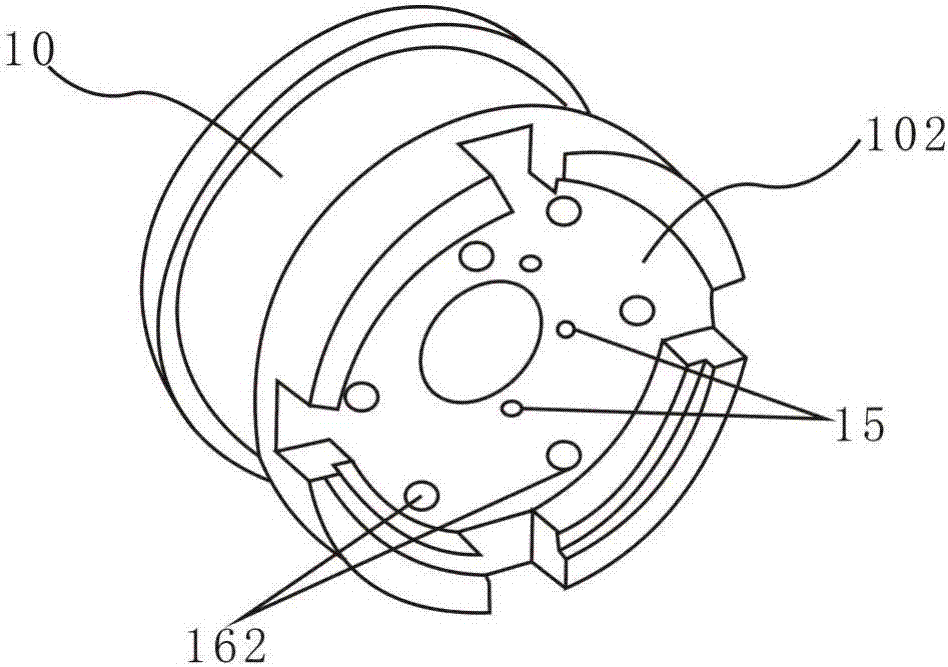

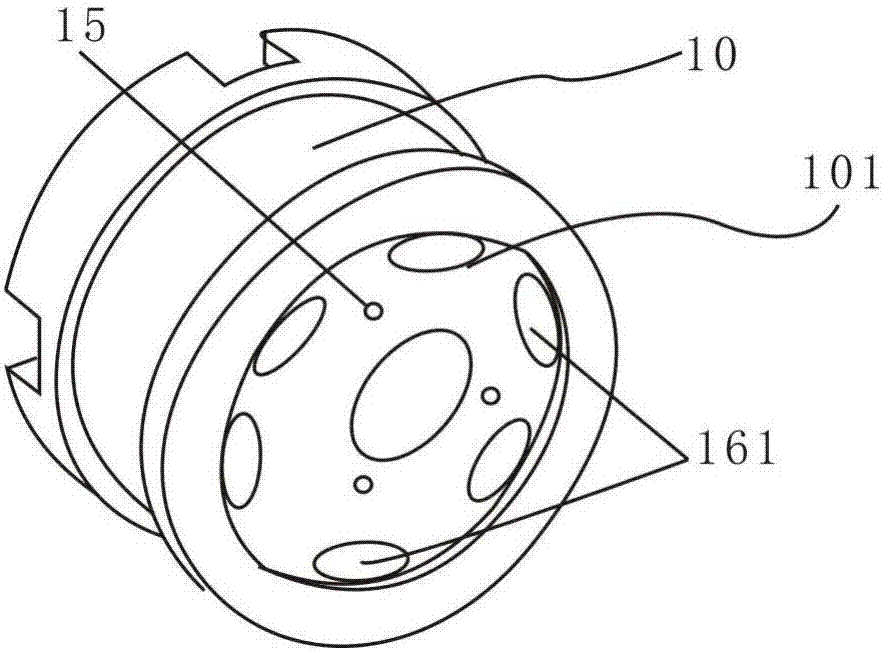

[0025] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0026] see Figure 1-3 , the structure of the suspension type oil replenishing and discharging piston provided by the present invention includes an oil replenishing and discharging piston 10, an oil discharging valve group 11 and an oil replenishing valve group 12; one end of the oil replenishing and discharging piston is embedded with a first Accommodating groove 101, the second accommodating groove 102 is embedded in the other end of the oil replenishment and discharge piston, the oil discharge valve group is installed in the first accommodating groove, and the oil replenishing valve group is installed in the second accommodating In the groove; the first spring 13 for limiting the movement stroke of the oil discharge valve plate set is arranged between the notch of the first accommodation groove and the oil disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com