Honeycomb sandwich structure and section steel combined rectangular steel arch tunnel supporting structure

A technology of honeycomb sandwich structure and support structure, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as large deformation of broken strata, and achieve the effects of increasing stability, increasing moment of inertia, and increasing stiffness

Pending Publication Date: 2022-05-31

CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem to be solved by the present invention is to overcome the deficiencies and defects mentioned in the above background technology, and provide a honeycomb sandwich structure with large support contact area, good stability, strong deformation resistance, simple structure and good economic effect. Rectangular steel arch tunnel support structure combined with section steel, especially used to solve the control problem of high ground stress, weak and large deformation of broken ground

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

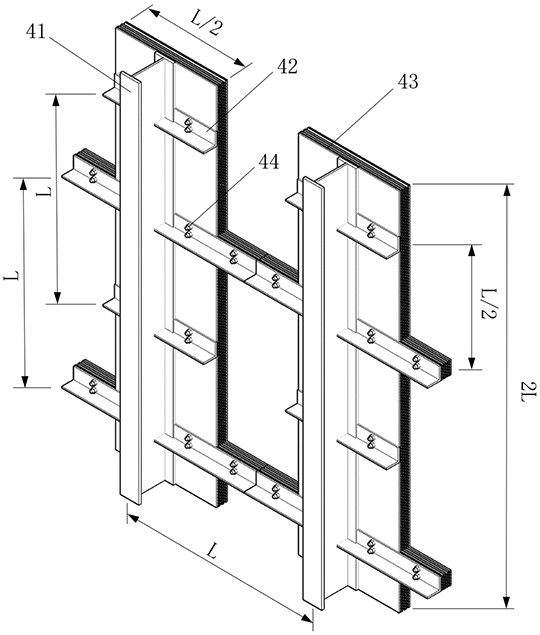

[0036] In this embodiment, the width of the rectangular steel arch 4 combined with the honeycomb sandwich structure and section steel is L / 2, and the length is 2L. bee

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

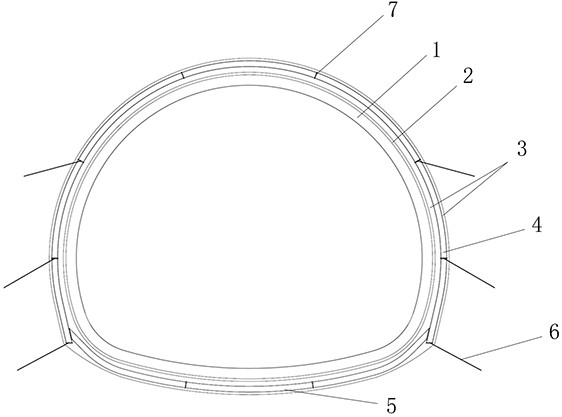

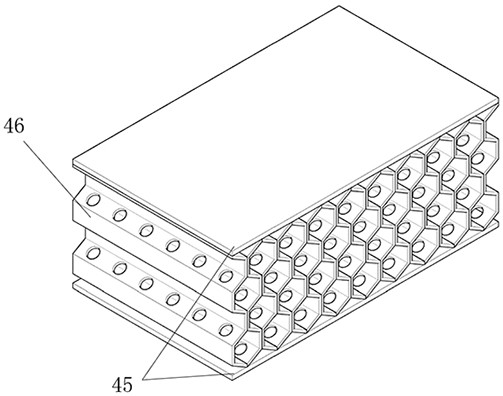

The invention discloses a honeycomb sandwich structure and profile steel combined rectangular steel arch tunnel supporting structure which comprises a secondary lining layer, a waterproof layer, a primary support sprayed concrete layer, an upper rectangular steel arch formed by combining a plurality of sections of honeycomb sandwich structures and profile steel, a bottom traditional strip-shaped steel arch, feet-lock bolts and connecting devices between the steel arches. The surface of the rectangular steel arch combined by the upper multi-section honeycomb sandwich structure and the profile steel is rectangular, the contact area of the steel arch and surrounding rock is increased, the surface is of a layer of honeycomb sandwich structure, the honeycomb sandwich structure deforms through stress of surrounding rock, energy of the surrounding rock is released, and the energy of the surrounding rock is released. The deformation amount of the steel arch under different tunnel conditions can be met by adjusting the number of layers of honeycombs in the honeycomb sandwich structure, so that the supporting structure has the capacity of coordinating deformation with surrounding rocks and also has the rigidity for preventing the surrounding rocks from deforming excessively. The problem that a high-crustal-stress soft rock large-deformation tunnel primary support is prone to deformation and damage can be effectively solved.

Description

A rectangular steel arch tunnel support structure combining honeycomb sandwich structure and section steel technical field The invention belongs to technical field of tunnel engineering, be specifically related to a kind of rectangular steel combined with honeycomb sandwich structure and section steel Arch tunnel support structure. Background technique With the continuous development of my country's transportation construction industry, the problem of high ground stress in deep buried tunnels in weak strata has become a The leading factor endangering the safety of tunnel engineering. The rock mass around the tunnel often undergoes rapid deformation of a large magnitude, and the ensuing It is a thorny problem such as support distortion, damage and intrusion into the clearance. If the high ground stress is not properly released, it is easy to cause secondary lining in the later stage. The cracking and deformation of the masonry will seriously affect the safety and nor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21D11/20

CPCE21D11/20Y02E10/20

Inventor 李宁刘宝莉陈志敏赵维飞王洪杨易朴蒋逸文

Owner CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com