LED filament lamp

A technology of LED filament lamps and LED filaments, which is applied to lighting devices, light sources, and light source fixation, can solve problems such as high cost and inconvenient operation, and achieve the effects of simple structure, cost saving, and support for automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Please refer to Figure 1-4 , Embodiment 1 of the present invention is:

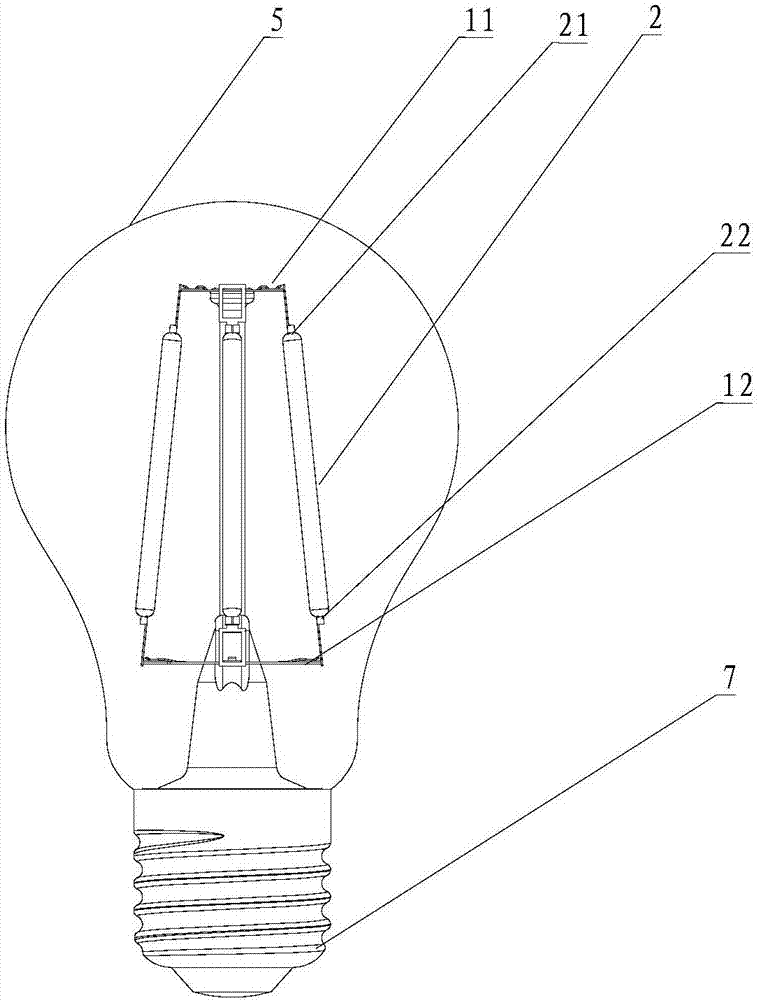

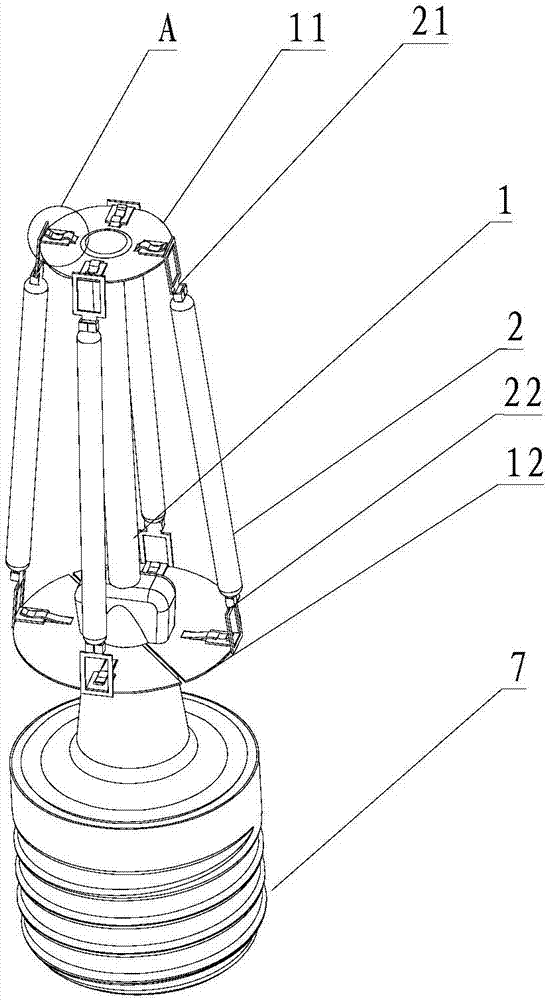

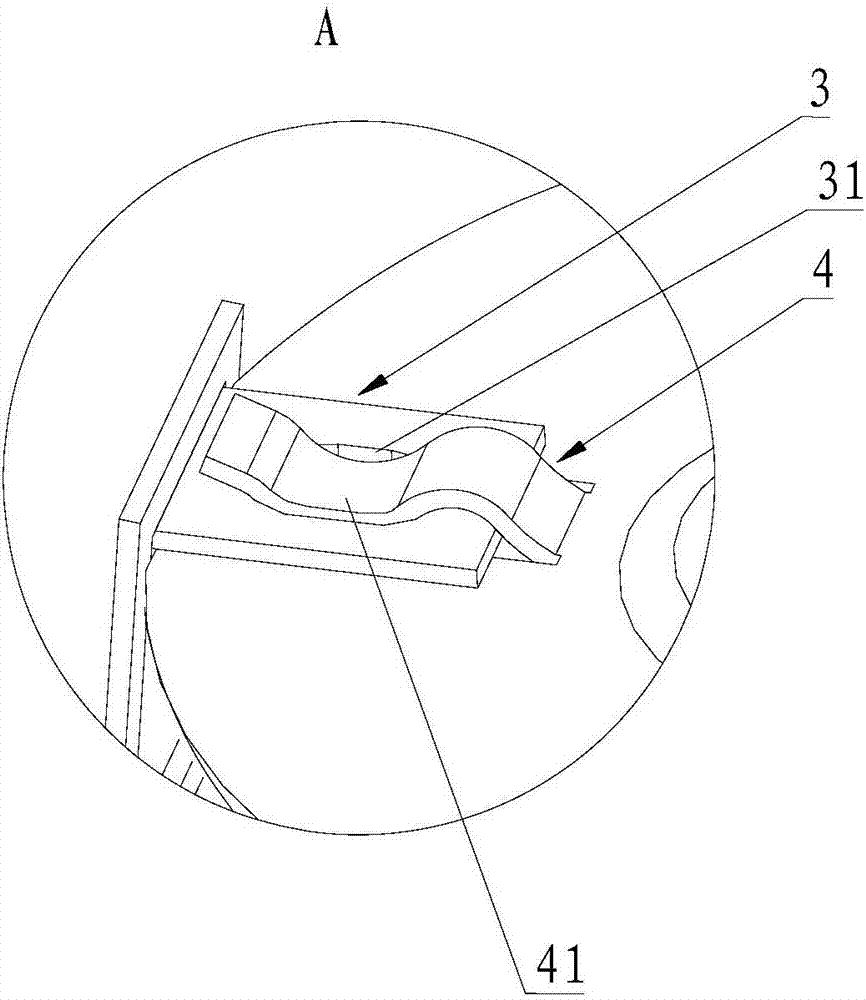

[0043] The LED filament lamp of this embodiment is composed of a lampshade 5, an LED filament strip 2, a stem 1, a driving part 6 and a lamp cap 7, and the stem 1, the LED filament strip 2 and the driving part 6 are respectively covered on the lampshade 5, the lampshade 5 is fixedly connected with the lamp cap 7. The two electrode ends of the LED filament strip 2 are provided with a connection structure 3, and the top and bottom positions of the glass stem 1 are correspondingly fixed with a disk-shaped first connection platform 11 and a second connection platform 12 with a conductive part 4. A connection platform 11 and a second connection platform 12 are arranged in parallel, and the first connection platform 11 arranged on the top is a small disc with a smaller size, and the small disc is integrally formed and inseparable; the second connection platform 12 located at the bottom It is a larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com