Adjustable light condensation plate drying device and using method thereof

A drying device and concentrating plate technology, which is applied in the directions of drying gas arrangement, drying solid materials, drying, etc., can solve problems such as energy waste, and achieve energy saving and flexible heating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

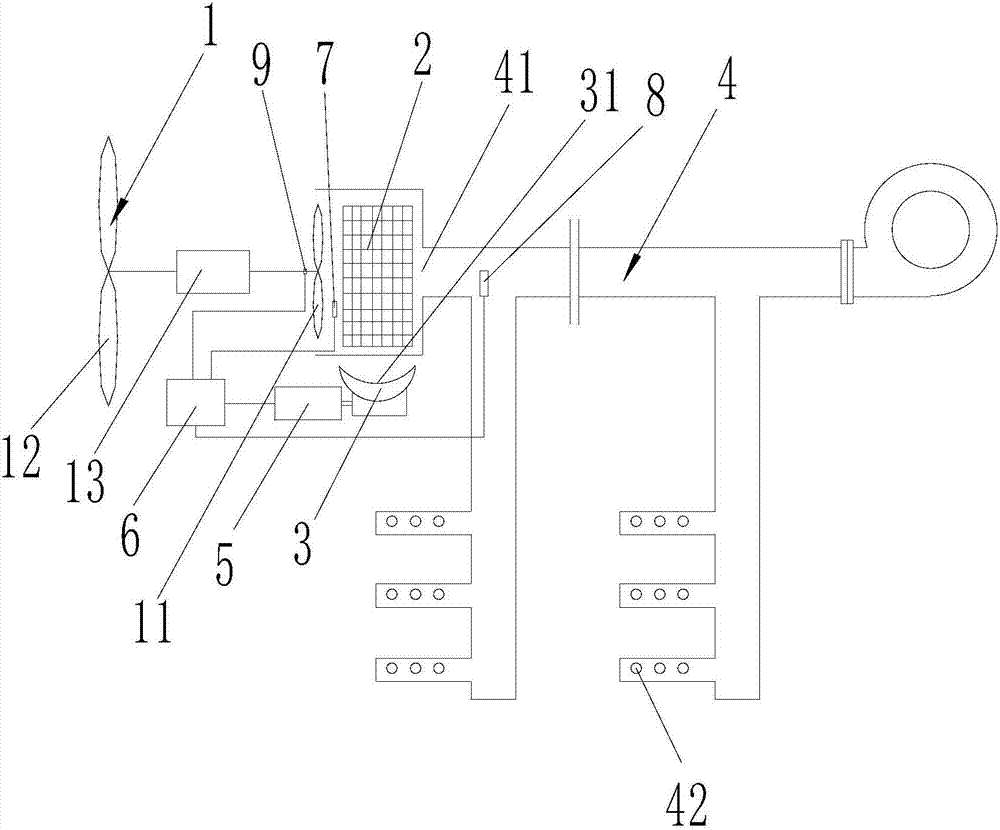

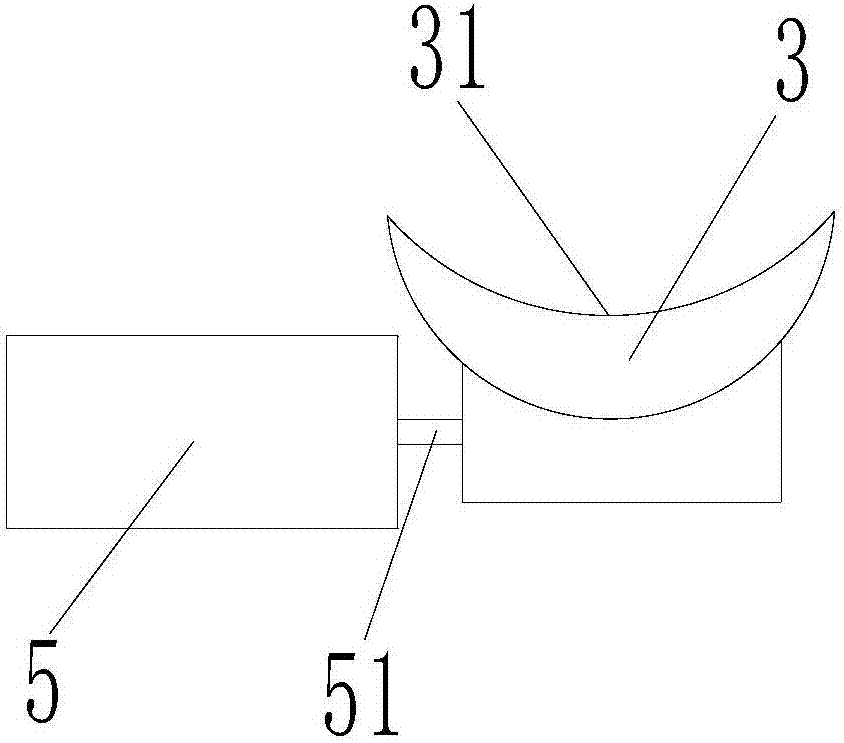

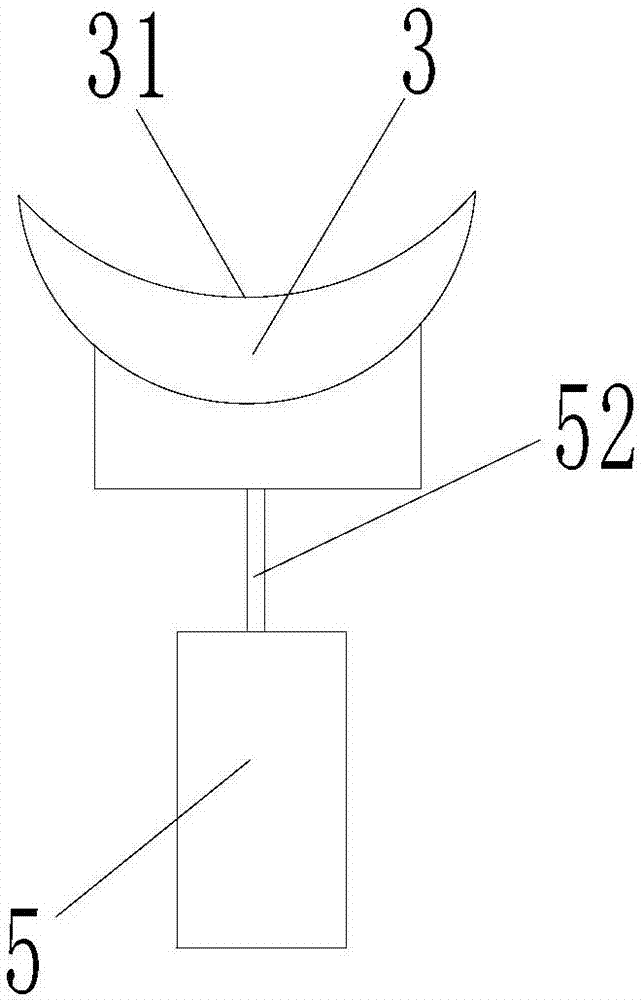

[0044] Such as figure 1 As shown, an adjustable condensing plate drying device includes an air supply device 1 , a heat exchanger 2 , a condensing plate 3 , an air equalizing device 4 and a driving mechanism 5 . The air equalizing device 4 has an air inlet 41 and an air exhaust port 42, the air supply device 1 corresponds to the air inlet 41, and the air supply device 1 blows air into the air equalizing device 4 through the air inlet 41, and the exhaust air of the air equalizing device 4 Port 42 is discharged to dry the external material. The heat exchanger 2 is arranged on the air inlet 41, and the concentrating plate 3 has a reflective surface 31 that can correspond to the heat exchanger 2, and the reflective surface 31 can receive sunlight and reflect it to the heat exchanger 2 to reflect the heat exchanger 2. Heating is performed so that the heat exchanger 2 can heat the air entering the air equalizing device 4 through the air inlet 41 . The driving mechanism 5 is connec...

Embodiment 2

[0058] One aspect of the present invention provides a method for using an adjustable concentrating plate drying device, using the adjustable concentrating plate drying device described in Example 1;

[0059] Such as Figure 4 As shown, it includes: the heating step of the heat exchanger, adjusting the position of the concentrating plate by driving the movement of the concentrating plate through the driving mechanism, so that the reflective surface of the concentrating plate corresponds to the heat exchanger accurately, and reflects sunlight to the heat exchanger through the reflective surface of the concentrating plate. on the heater to heat the heat exchanger;

[0060] In the air supply step, the air supply device blows air to the air inlet of the air equalizing device, so that the air absorbs the heat of the heat exchanger and enters the air equalizing device, and is discharged through the air outlet of the air equalizing device;

[0061] In the adjustment step, when the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com