Rotating direct-driven electric diaphragm

A direct-drive, aperture technology, applied in optics, optical components, instruments, etc., can solve problems such as high production costs and poor adjustment stability, and achieve the effects of reducing driving resistance, avoiding stuttering, and stabilizing lighting conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

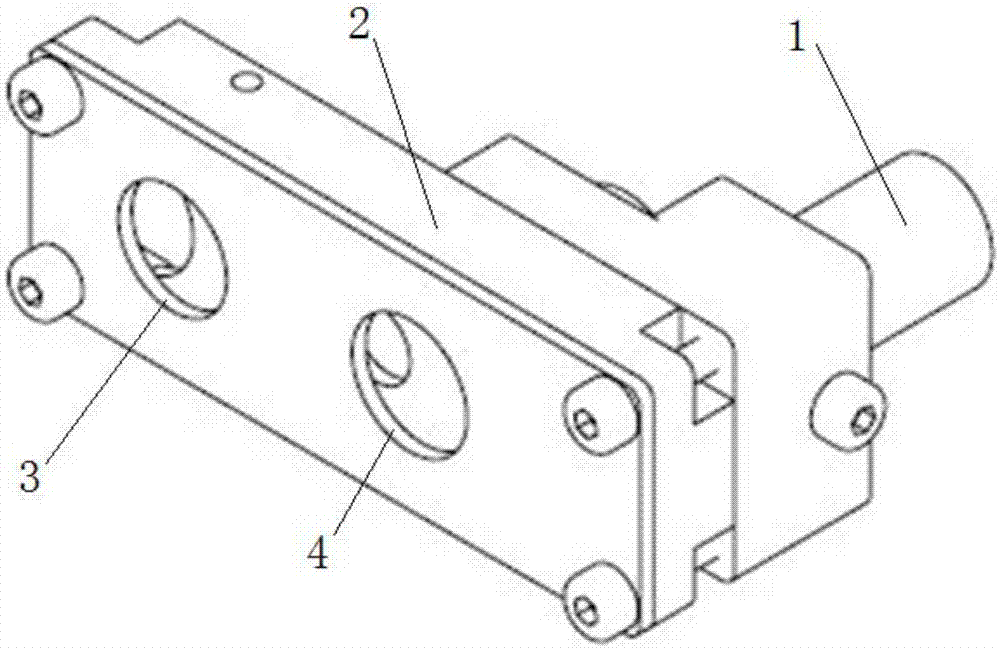

[0030] Such as figure 1 As shown, this embodiment is a rotary direct-drive electric diaphragm, which includes a motor 1 and a diaphragm main body 2 with a rectangular inner cavity.

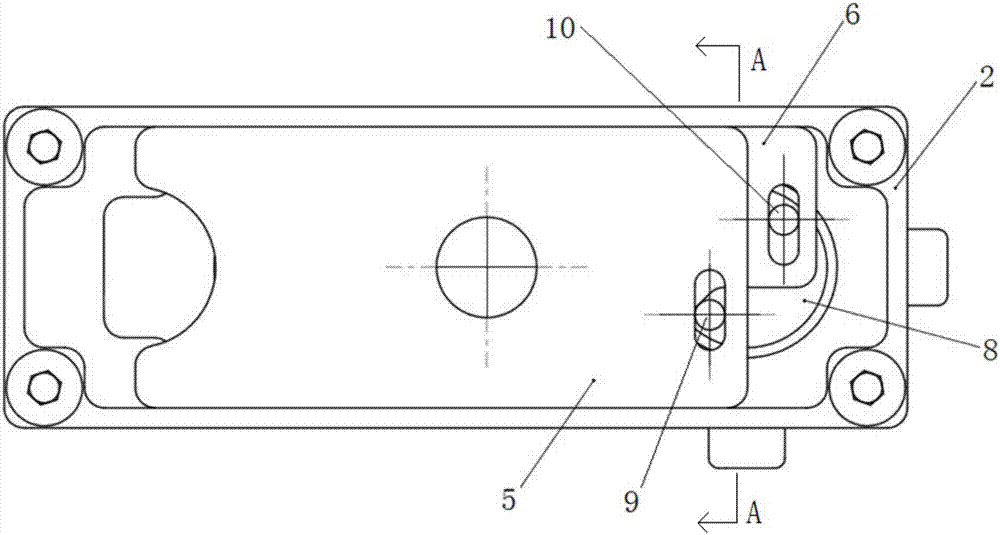

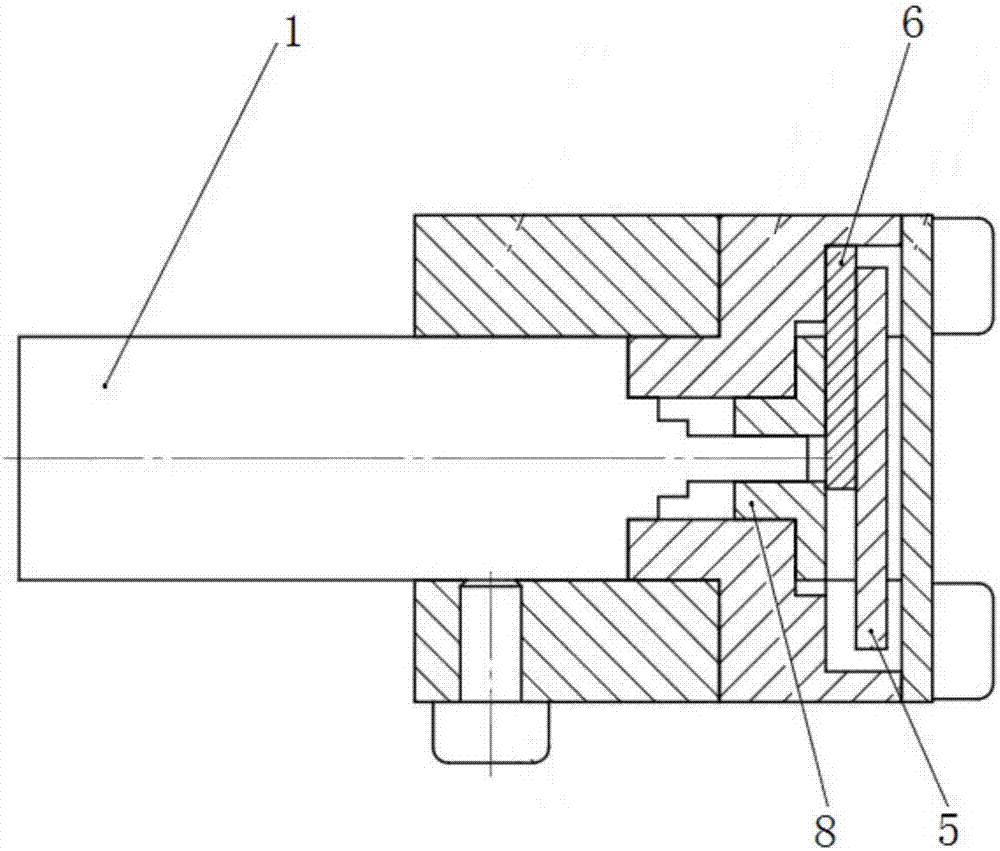

[0031] see Figure 2 to Figure 5 A rectangular first baffle 5 and a rectangular second baffle 6 are provided in the inner cavity of the diaphragm main body 2 , and the second baffle 6 is provided with a diaphragm hole 7 . The motor 1 is connected with the rotor 8, and the rotor 8 is provided with two first sliders 9 and a second slider 10 in eccentric positions, and the first baffle 5 and the second baffle 6 are respectively provided with two sliders. Compatible sliding grooves. Wherein, the two sliders are sliders with a cylindrical protrusion structure, and the sliding groove is a sliding groove with a waist-shaped hole structure. The motor 1 drives the rotor 8 to rotate, and the slider on the rotor 8 slides in the sliding groove, thereby driving the first baffle 5 and the second baffle 6 to ...

Embodiment 2

[0033] Such as Image 6 As shown, this embodiment is another rotary direct-drive electric diaphragm, which includes a motor 1 and a diaphragm main body 2 with a fan-shaped internal cavity, and the diaphragm main body 2 is provided with a light-through hole 3 and an illumination hole 4 .

[0034] see Figure 7 to Figure 10 , the inner cavity of the diaphragm main body 2 is provided with an adjusting baffle 12, and the two opposite sides of the adjusting baffle 12 are arc-shaped sides that are in sliding contact with the inner cavity of the fan-shaped structure. The motor 1 is connected with the rotor 8 , the rotor 8 is provided with a slider 13 at an eccentric position, and the adjusting baffle 12 is provided with a sliding groove matching the slider 13 . Wherein, the slider is a slider with a cylindrical protrusion structure, and the sliding groove is a sliding groove with a waist-shaped hole structure. The motor 1 drives the rotor 8 to rotate, and the slider on the rotor 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com