High pressure small flow string control valve

A regulating valve, a tiny technology, applied in the field of control valves, can solve the problems such as the inability to meet the small flow adjustment, the internal parts of the valve are easily damaged by erosion, and the flow channel of the labyrinth group is small, so as to ensure the sealing performance, avoid bending deformation, and throttle The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

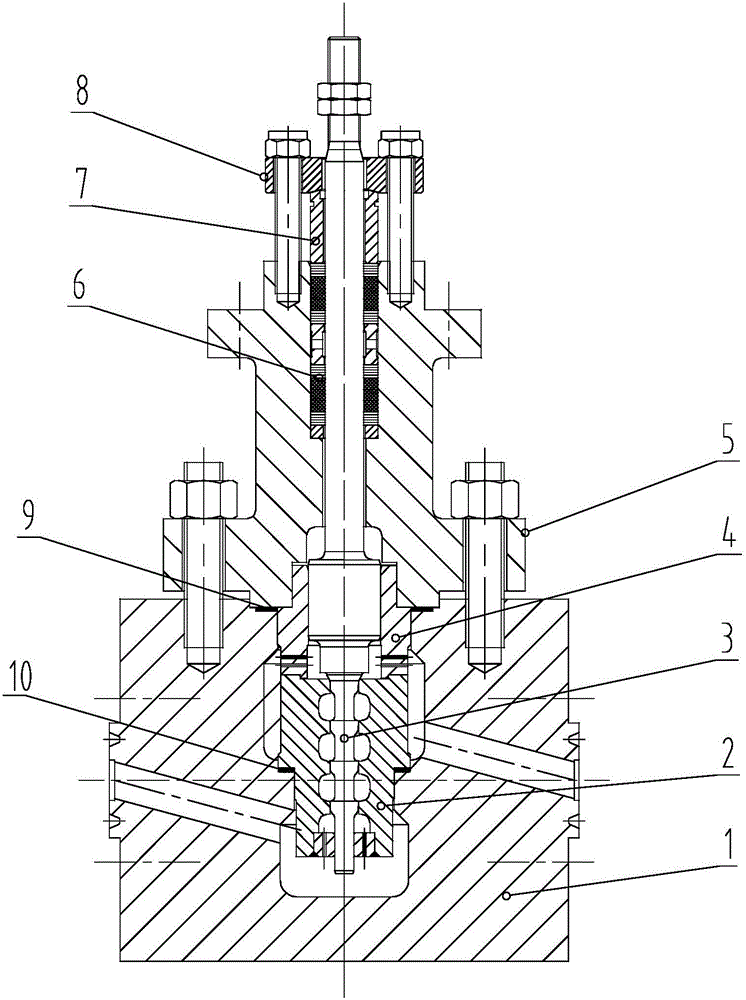

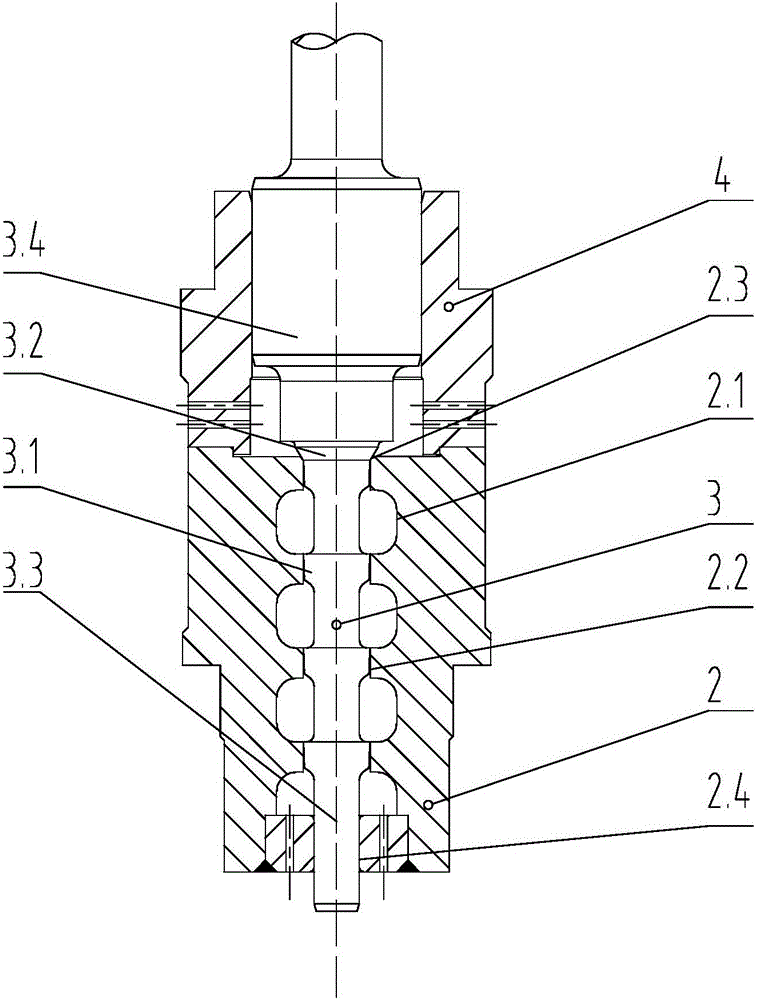

[0022] Such as Figure 1~2 As shown, the present invention mainly includes a valve body 1, a valve seat 2 is provided in the valve body 1, a second gasket 10 is provided between the valve body 1 and the valve seat 2, and a guide sleeve 4 is provided at the upper end of the valve seat 2. The upper end of the valve body 1 is connected to the upper cover 5 by bolts, and the upper cover 5 presses the guide sleeve 4 and the valve seat 2 in the valve body 1 , and a first gasket 9 is arranged between the valve body 1 and the upper cover 5 .

[0023] The upper end of the upper cover 5 is connected to the packing pressure plate 8 by bolts. A spool 3 is installed in the valve seat 2, and the upper end of the spool 3 passes through the guide sleeve 4 and the upper cover 5 to extend out of the packing plate 8. A packing 6 is arranged between the valve core 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com