Patents

Literature

30results about How to "Does not affect regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

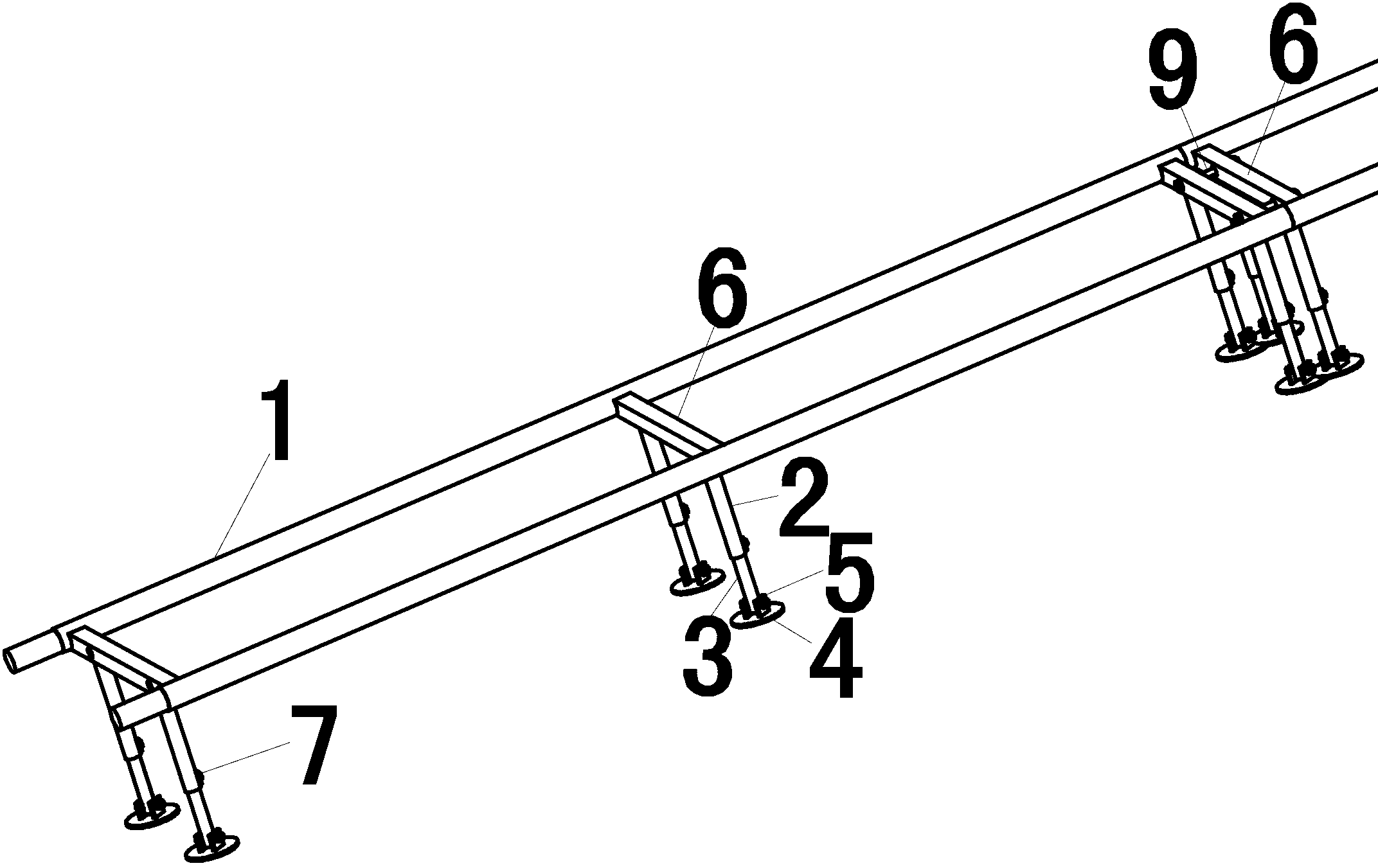

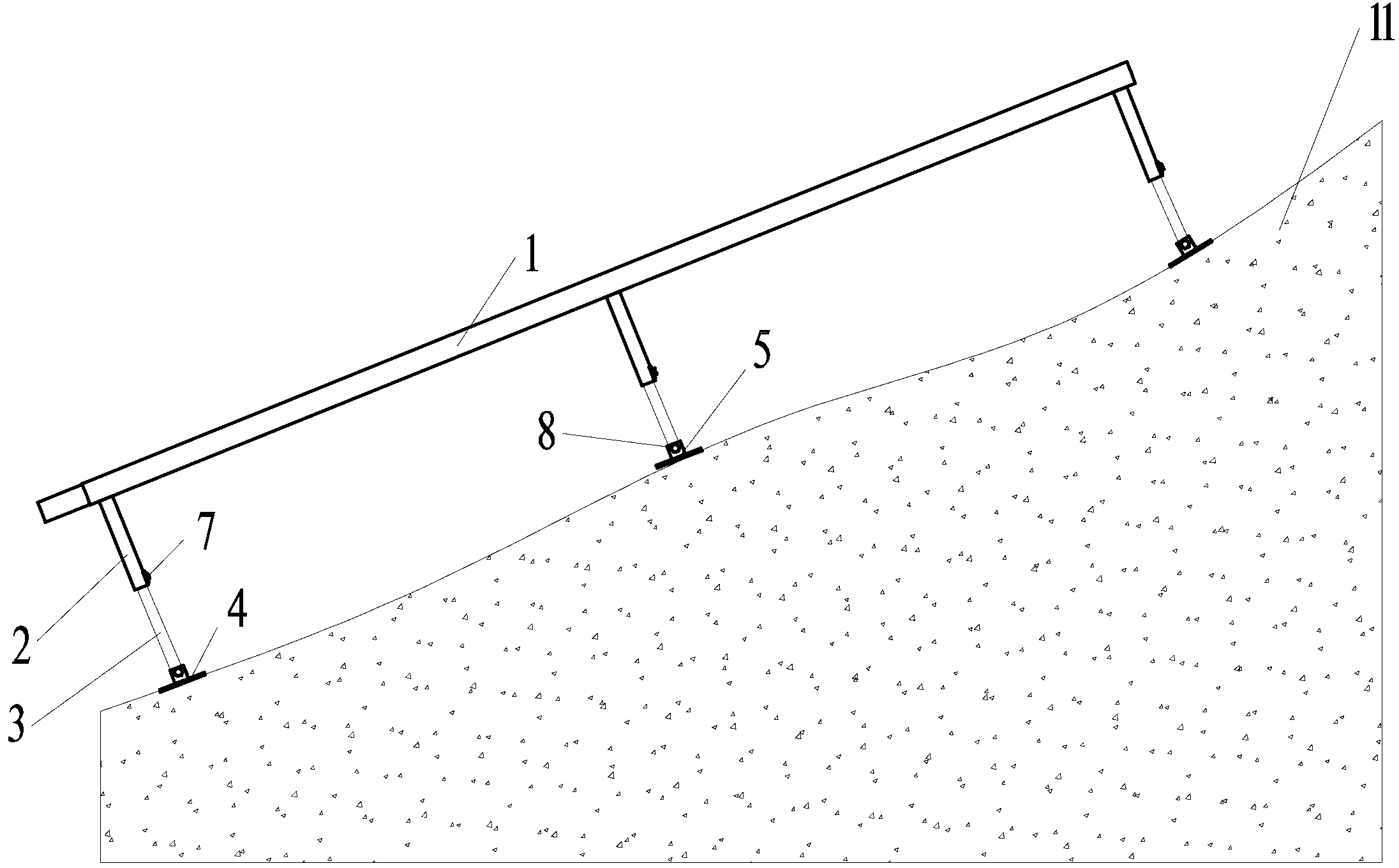

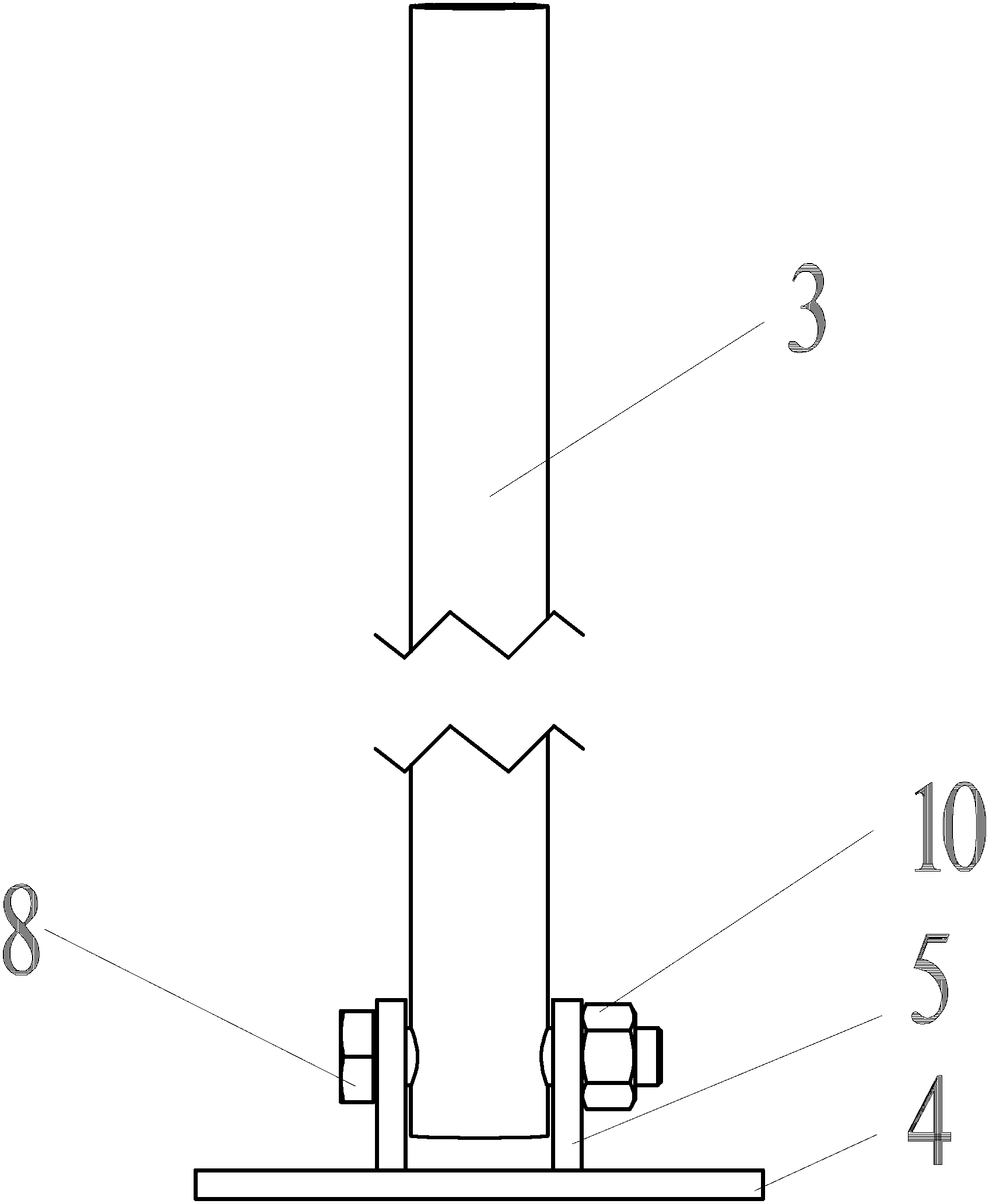

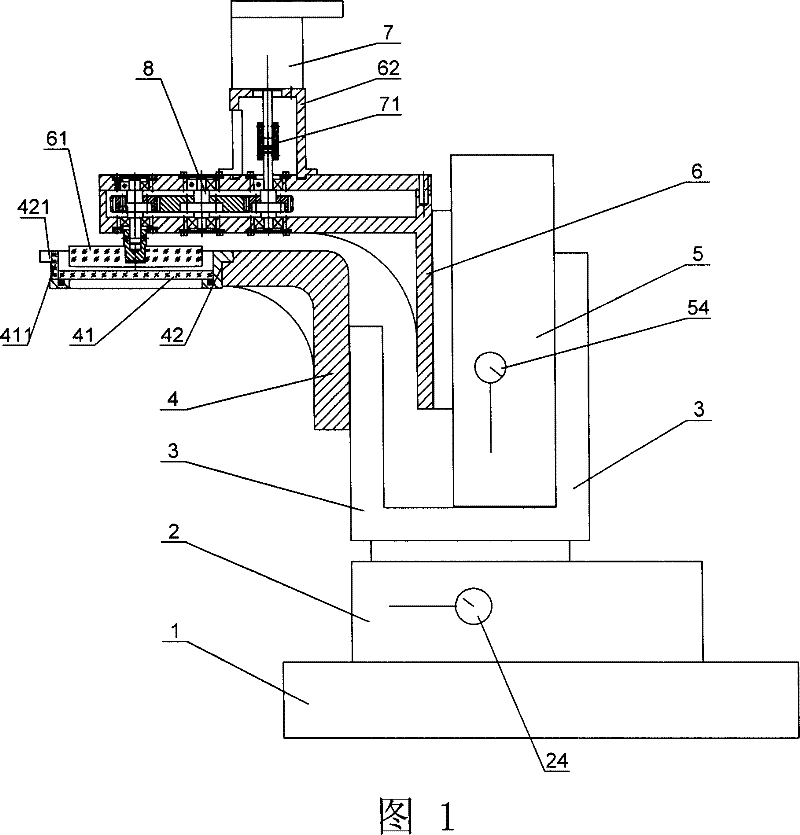

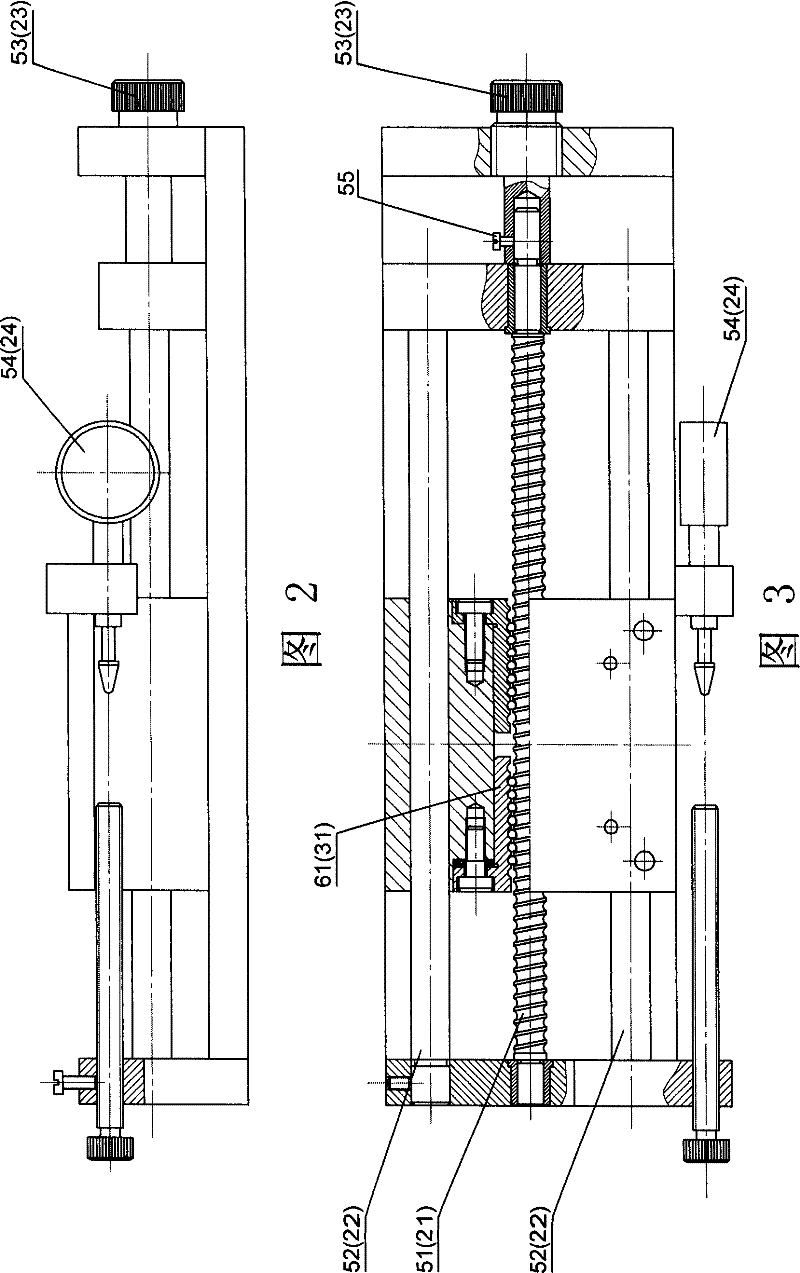

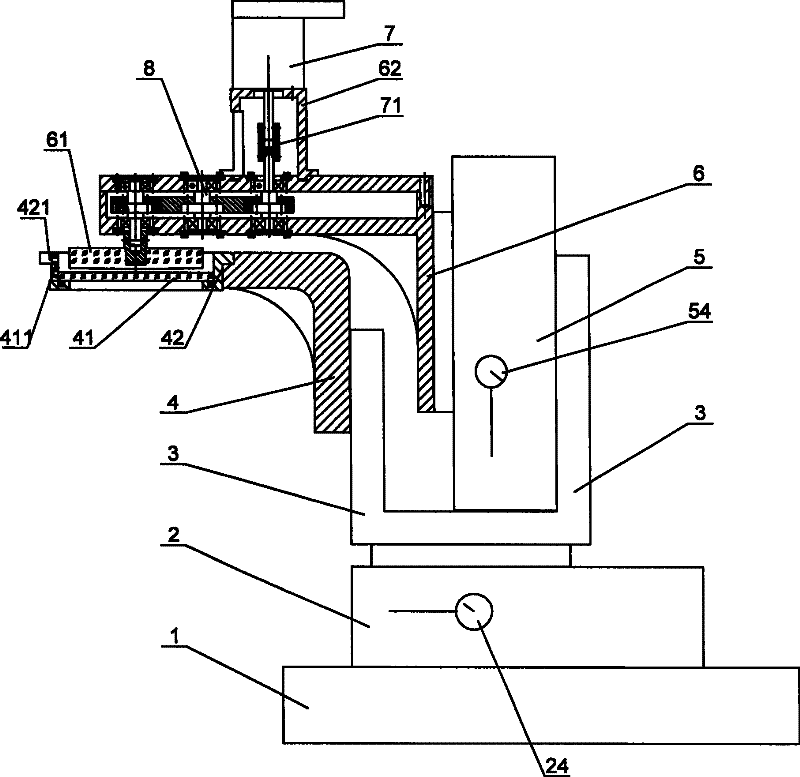

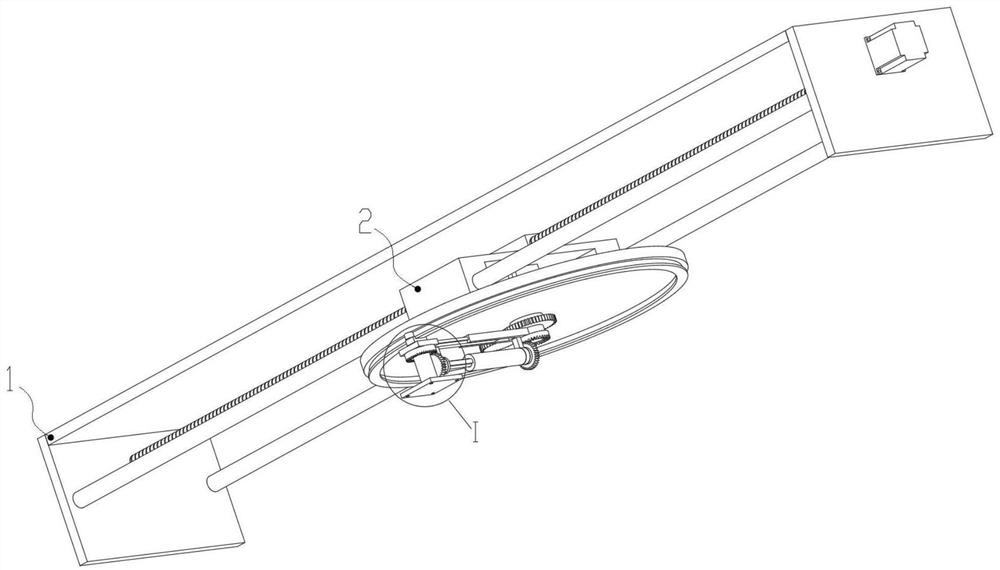

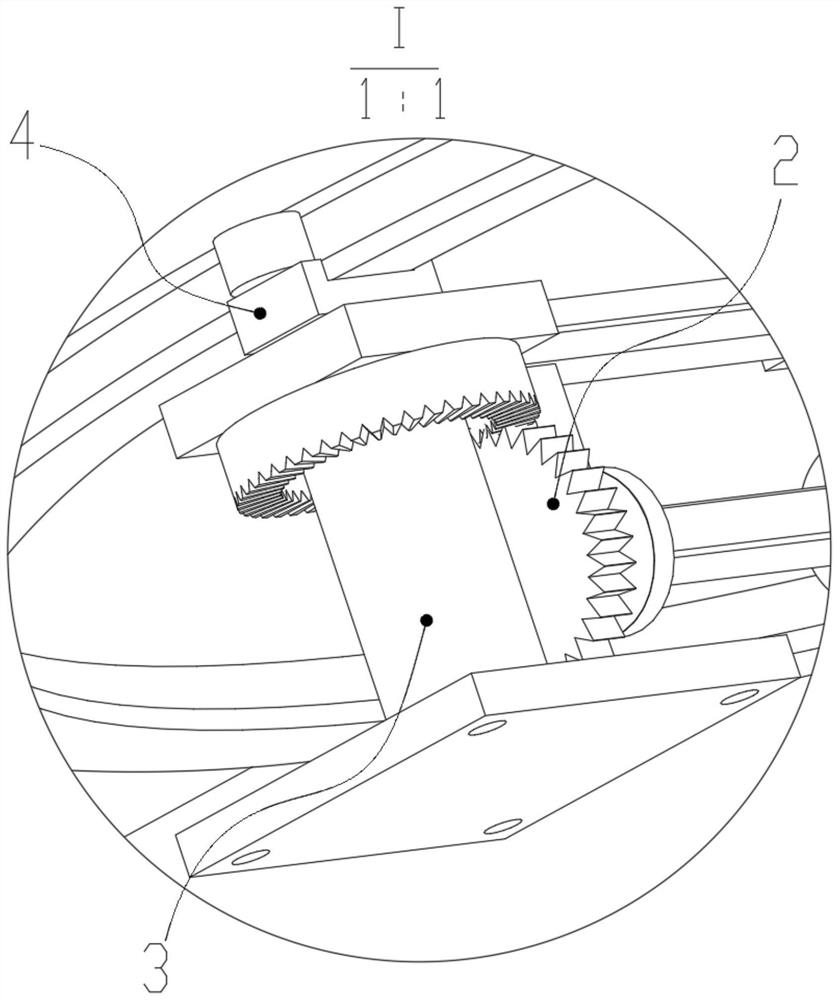

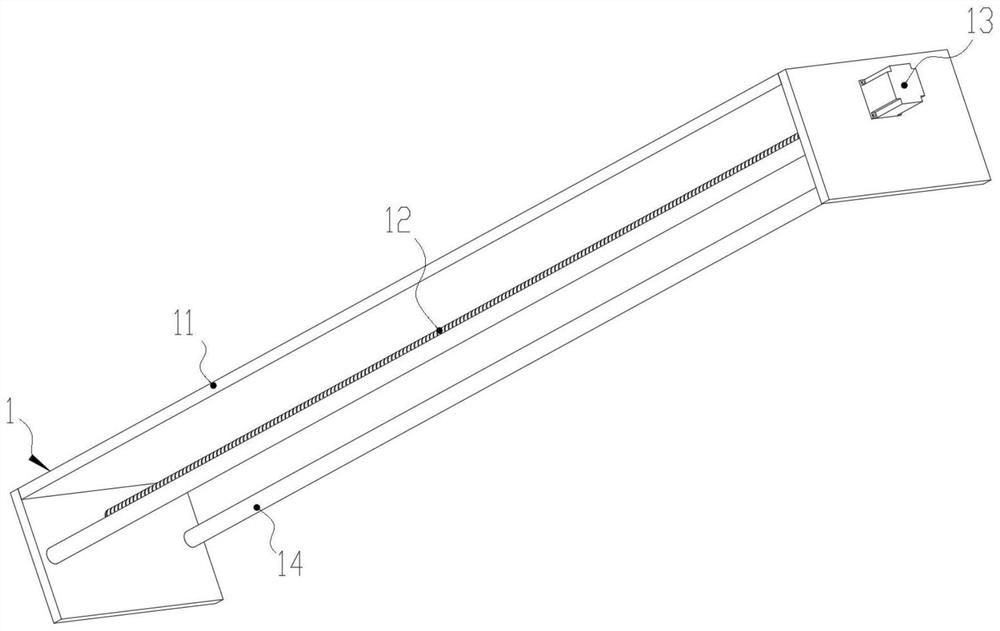

Supporting height adjustable and sole copying hillside orchard freight track

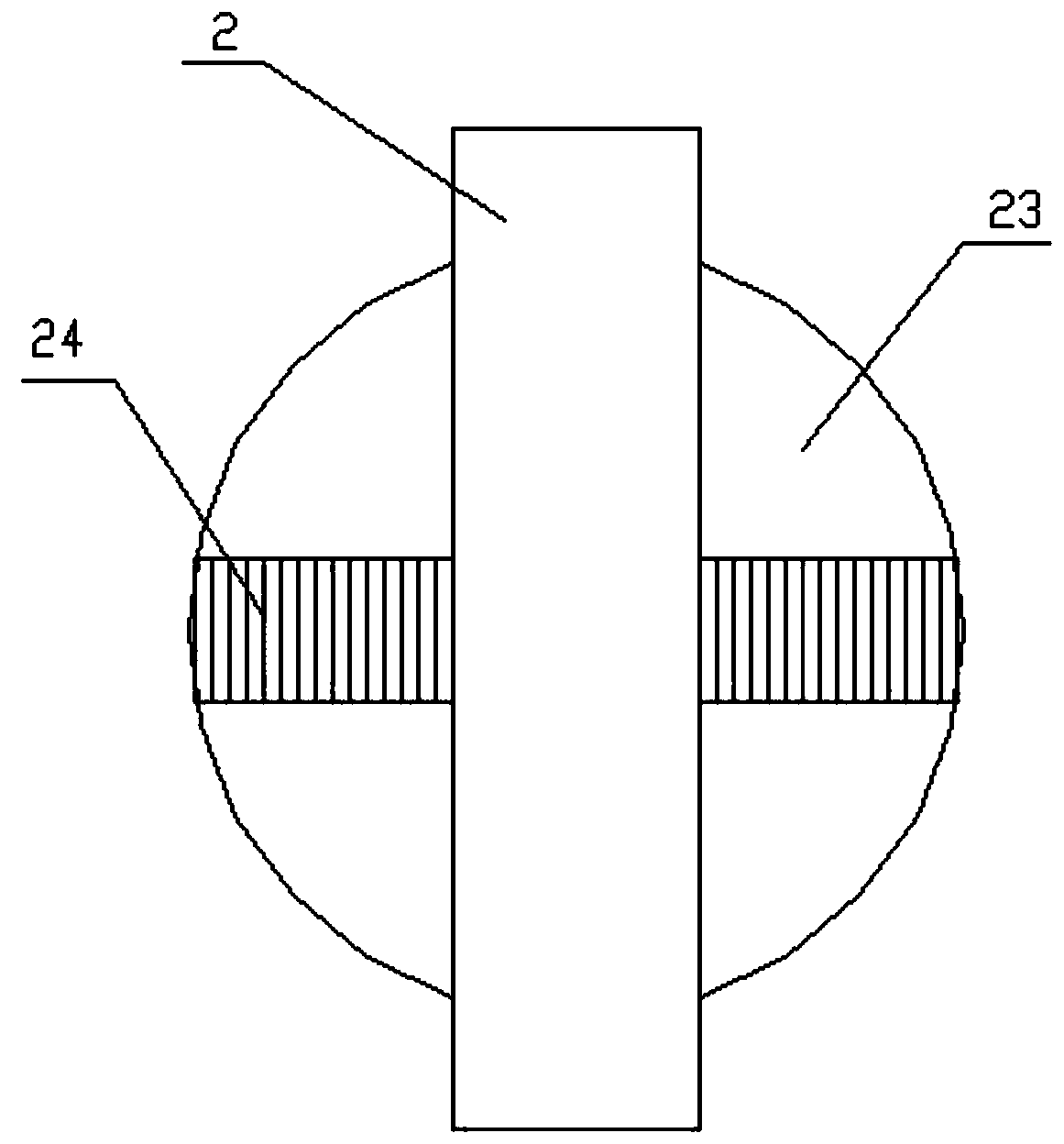

The invention discloses a supporting height adjustable and sole copying hillside orchard freight track. The supporting height adjustable and sole copying hillside orchard freight track comprises a track, first support columns, second support columns, support plates and connection clamp plates; more than two first support columns are connected to beams of the track; the front ends of the second support columns are inserted into the first support columns; the tail ends of the first support columns are provided with fixing devices; two connection clamp plates are arranged on the support plates; and the connection clamp plates are connected with the tail ends of the second support columns through first bolts. The supporting height adjustable and sole copying hillside orchard freight track has the advantages of solving the problems that the height of the track support columns and angles of the support plates cannot be adjusted, the utilization effect is poor and the like in the prior art, being simple in structure, easy to operate and high in production efficiency, being suitable for complex terrain of mountainous regions, being adjustable in support height, and the like. The sole allows copying.

Owner:SOUTH CHINA AGRI UNIV

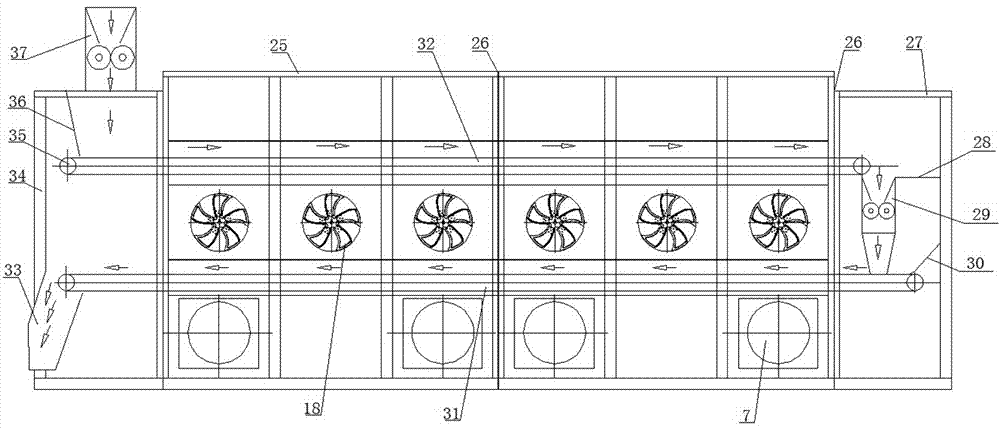

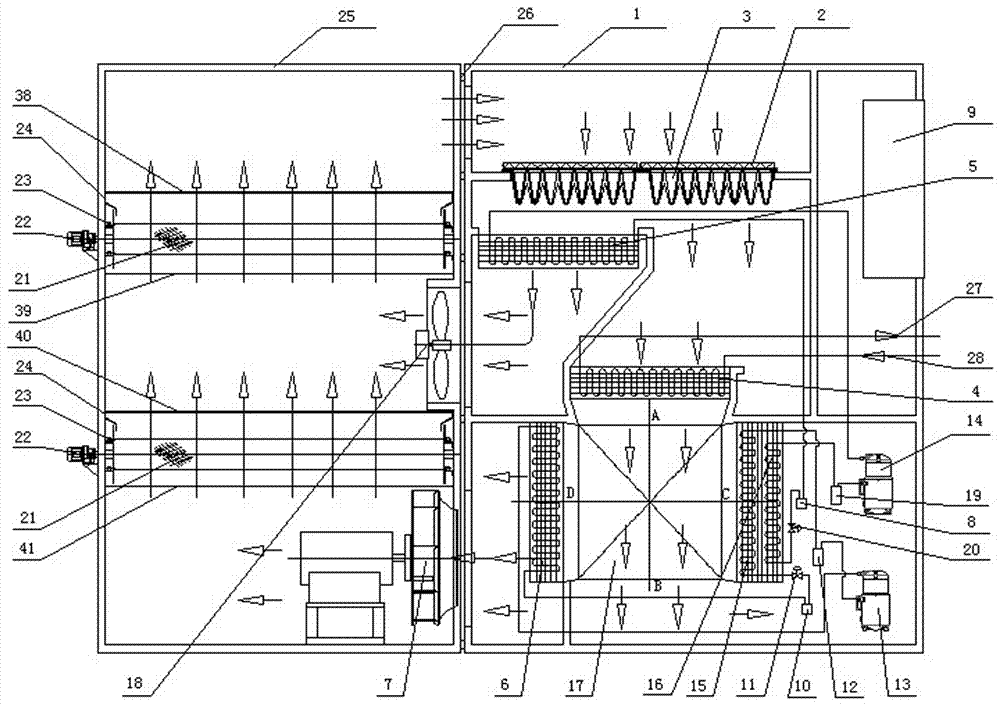

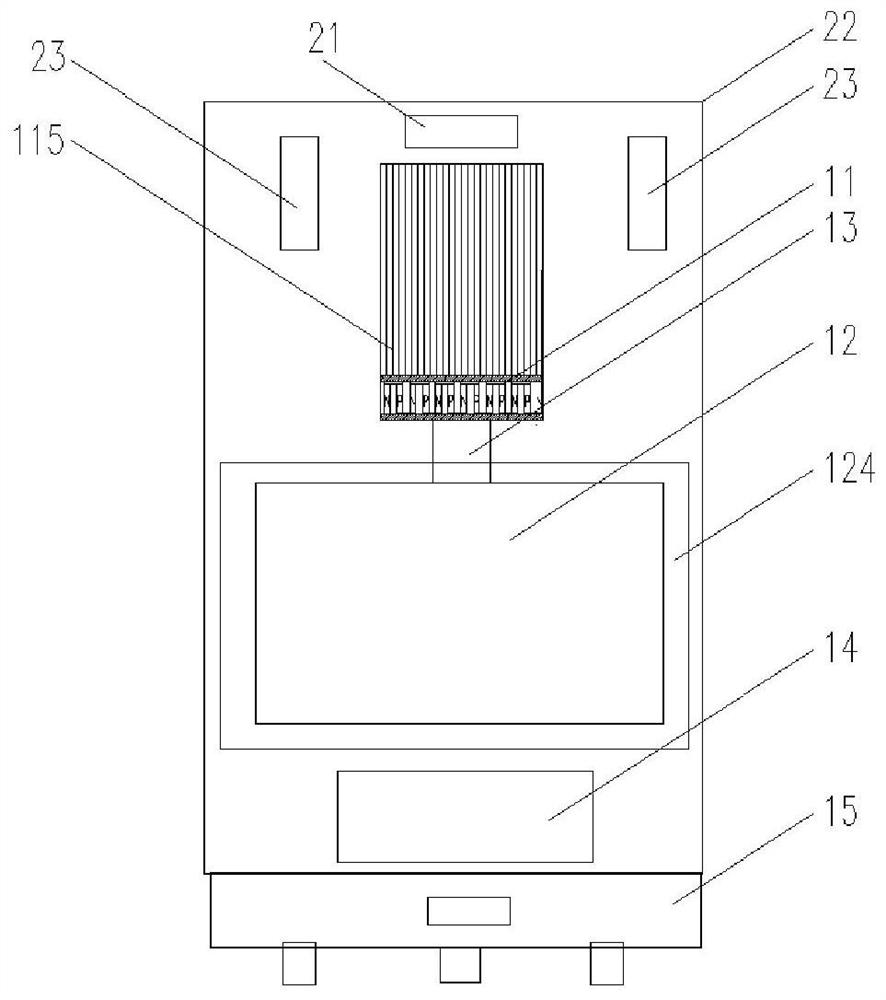

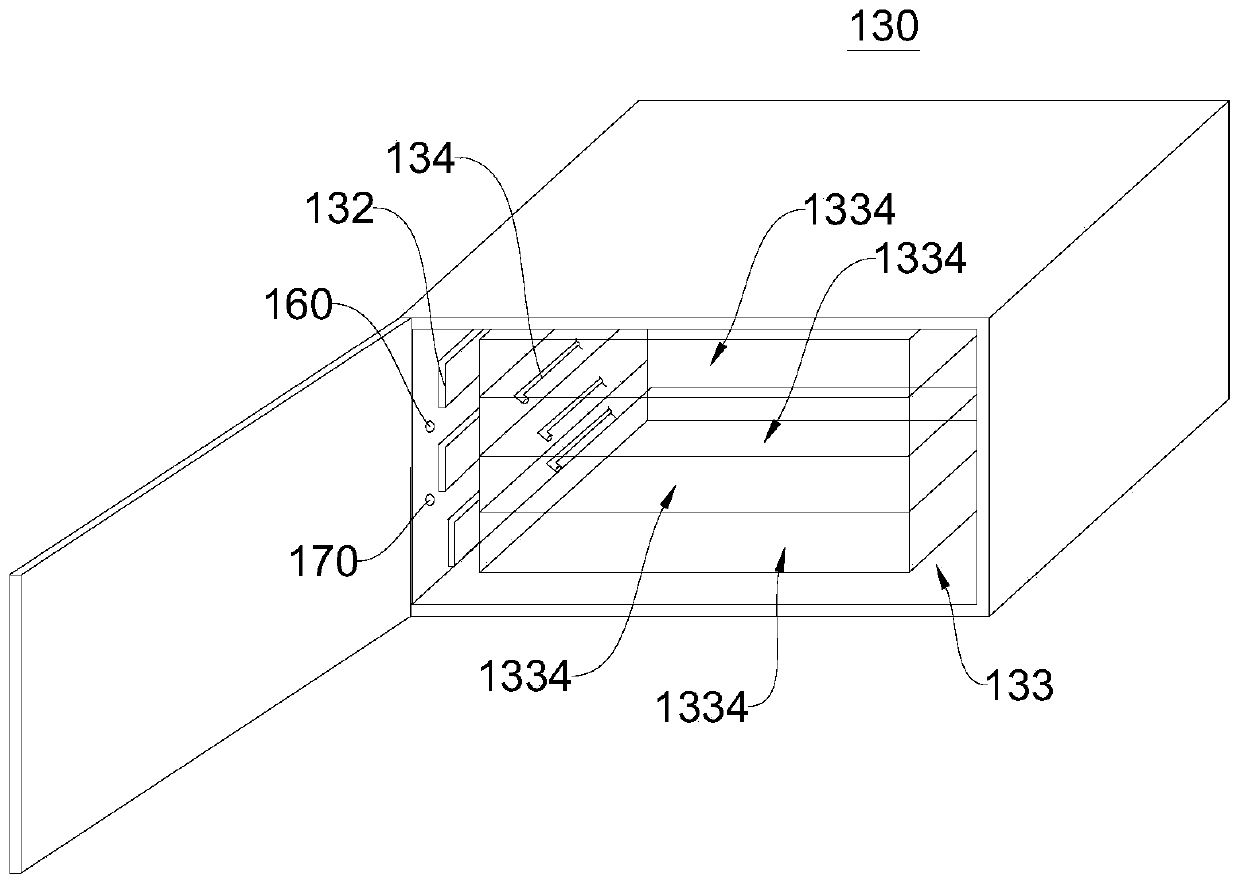

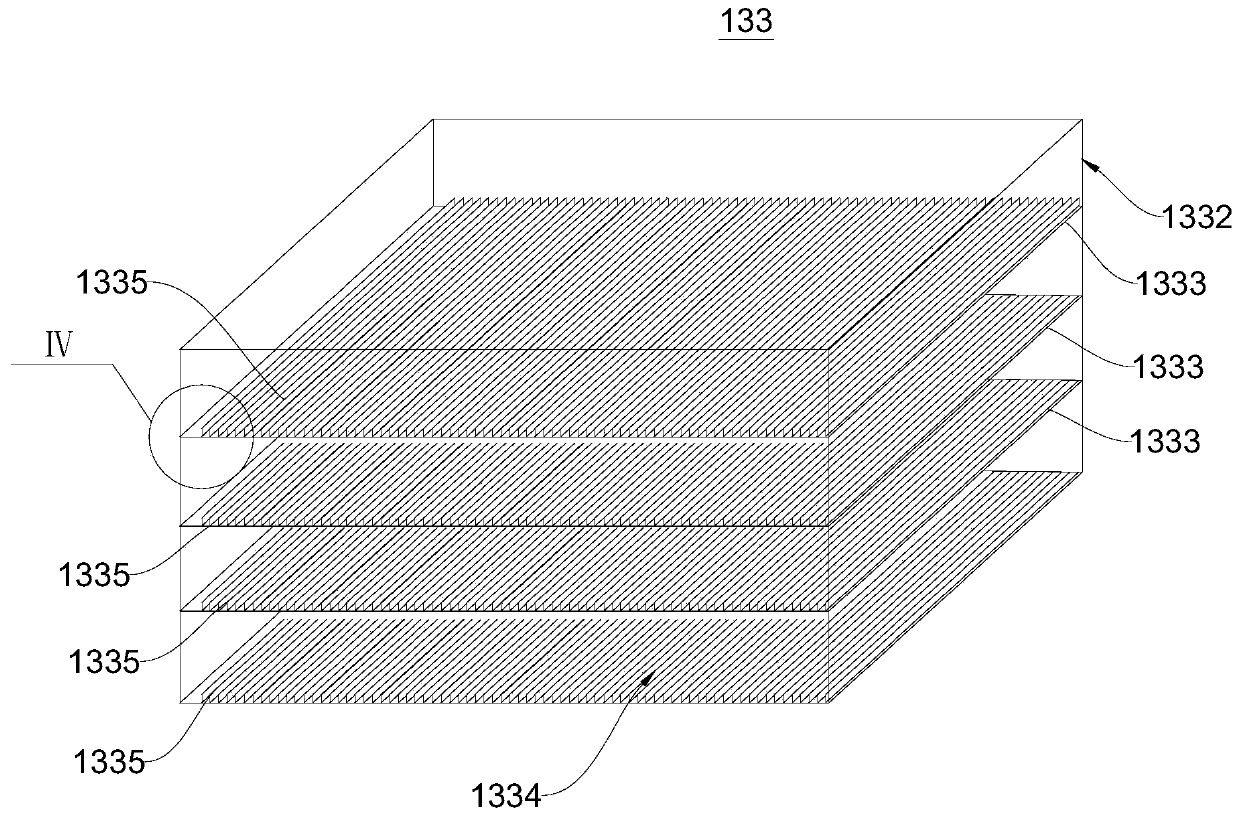

Energy recycling type temperature adjusting dehumidification sludge drying machine system

PendingCN107879594ANo emissionsWill not cause secondary environmental pollutionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeDry box

The invention discloses an energy recycling type temperature adjusting dehumidification sludge drying machine system. A sludge feeding bar cutting device is arranged at the top of an inlet / outlet transmission tank; sludge is extruded into a porous plate by using the sludge feeding bar cutting device through a rotating cutter; net strips are arranged inside a drying tank; a cut bar feeding device is arranged at one end of the net strip; a temperature adjusting dehumidification drying device is arranged on one side of the drying tank; the temperature adjusting dehumidification drying device is connected with the bottom of the drying tank through an air supply hole; the net strips are divided into two layers; the first layer of the net strips and the second layer of the net strips are arranged from top to bottom; the start end of the second layer of the net strips is arranged at the lower part of the tail end of the first layer of the net strips; materials of the first layer of the net strips drop into a crushing device at the tail end of first layer of the net strips; crushed sludge drops onto the start end of the second layer of the net strip and finally drops into a discharge hole.By adopting the system, sludge of which the water content rate is within 80-65% can be effectively treated, sludge bar extrusion is not affected, flexible adjustment is achieved, the supply amount can be adjusted through variable frequency of a screw rod pump, a good and uniform spreading effect is achieved, the air permeability of sludge bars can be adjusted, and the requirements of different types of sludge bar extrusion can be met.

Owner:BRIGHT AIR CONDITIONING

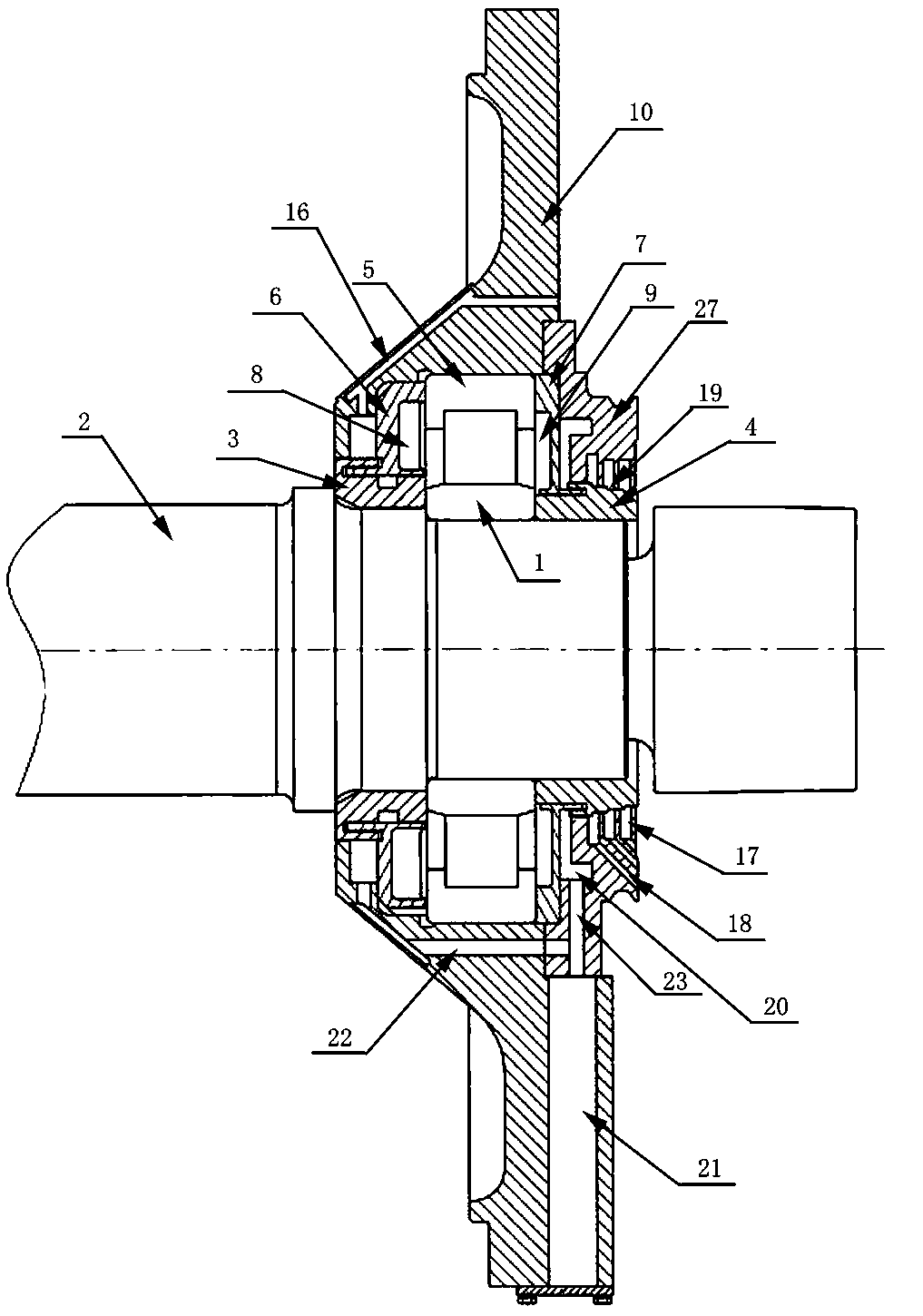

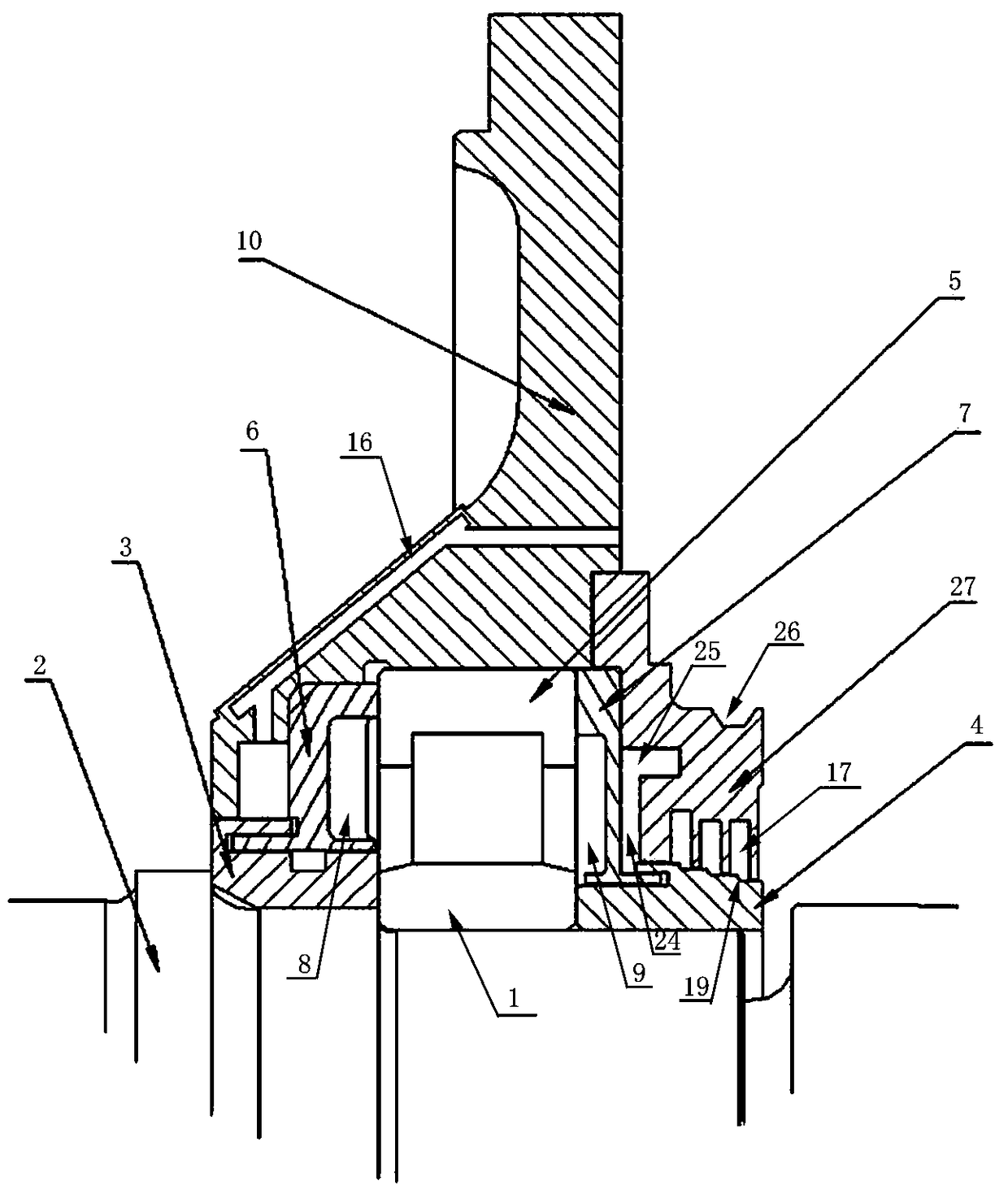

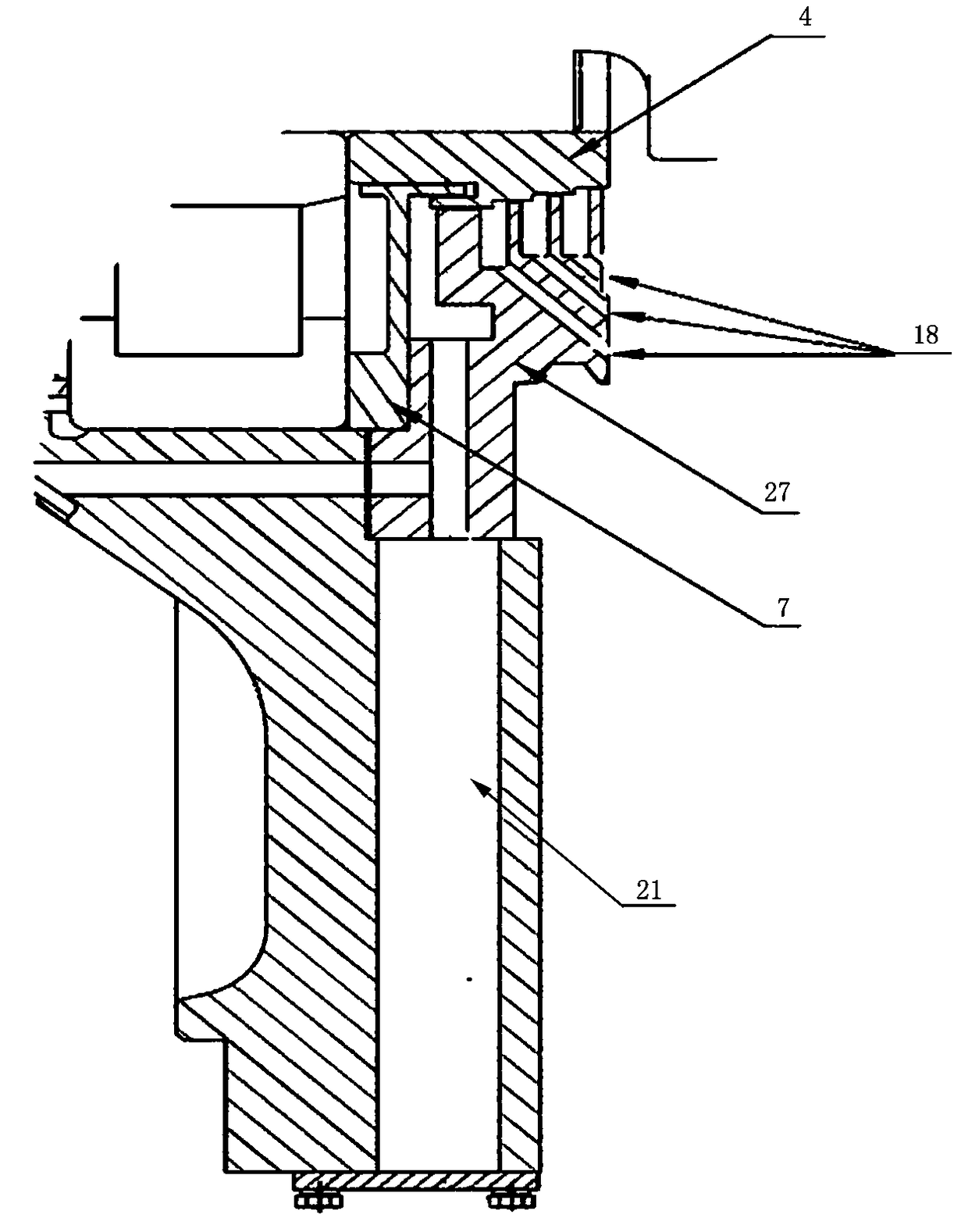

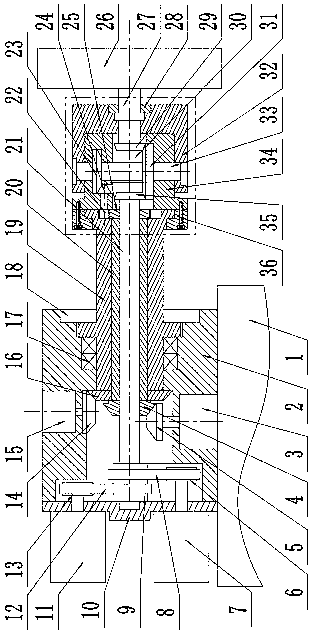

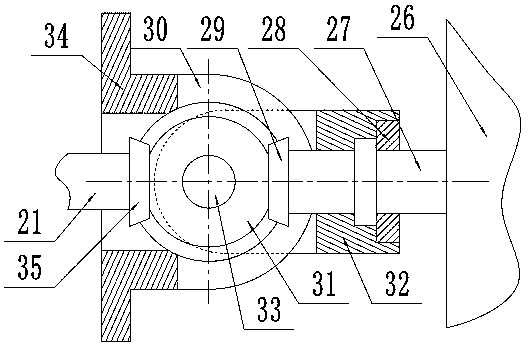

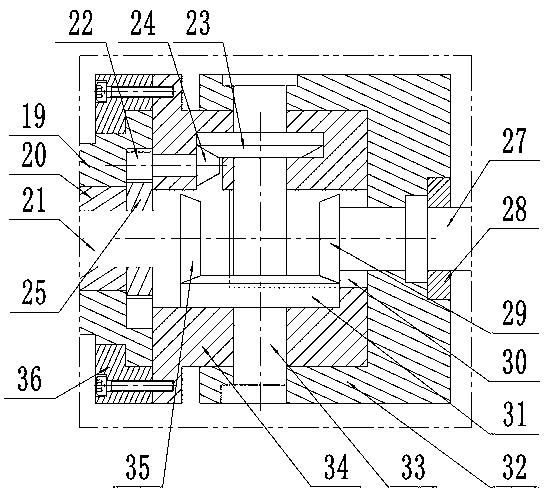

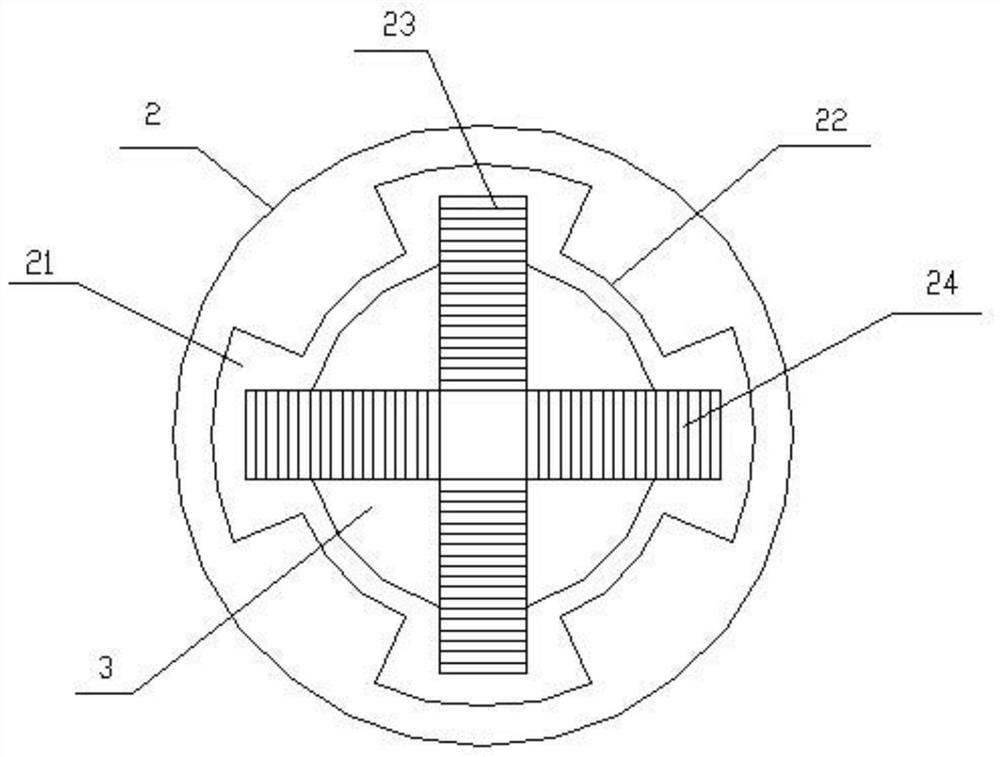

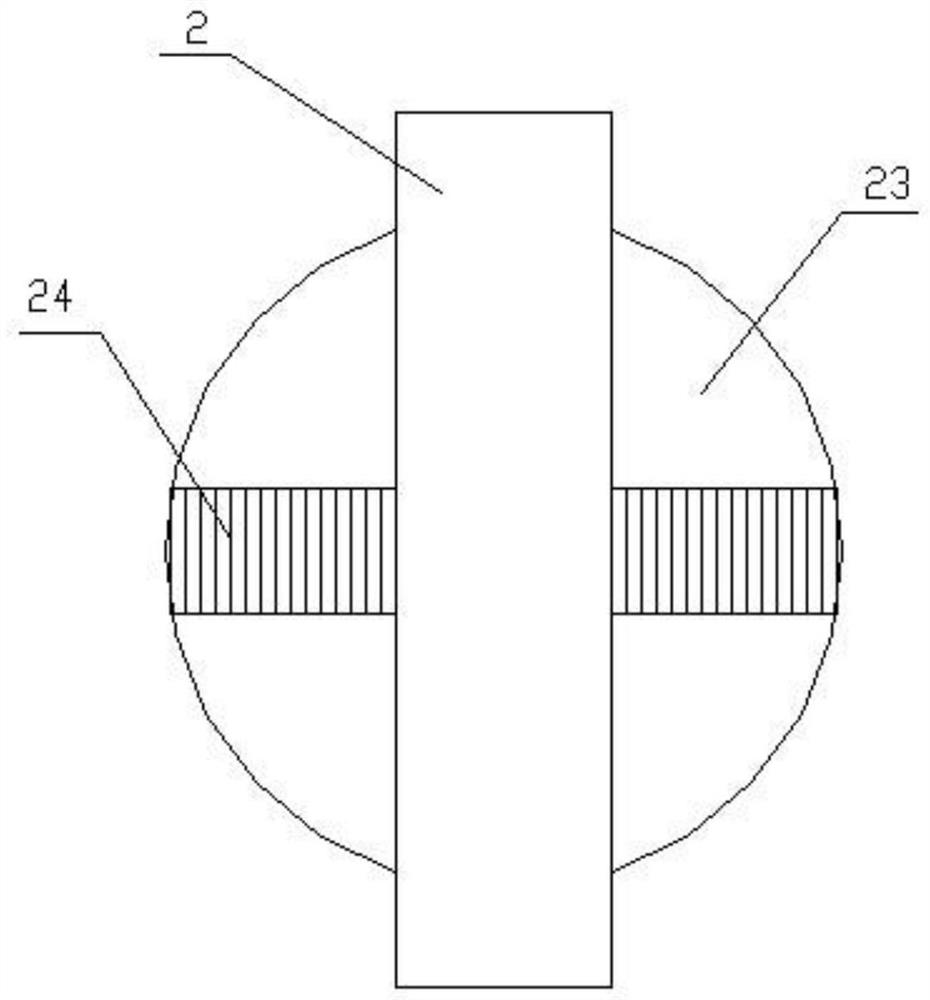

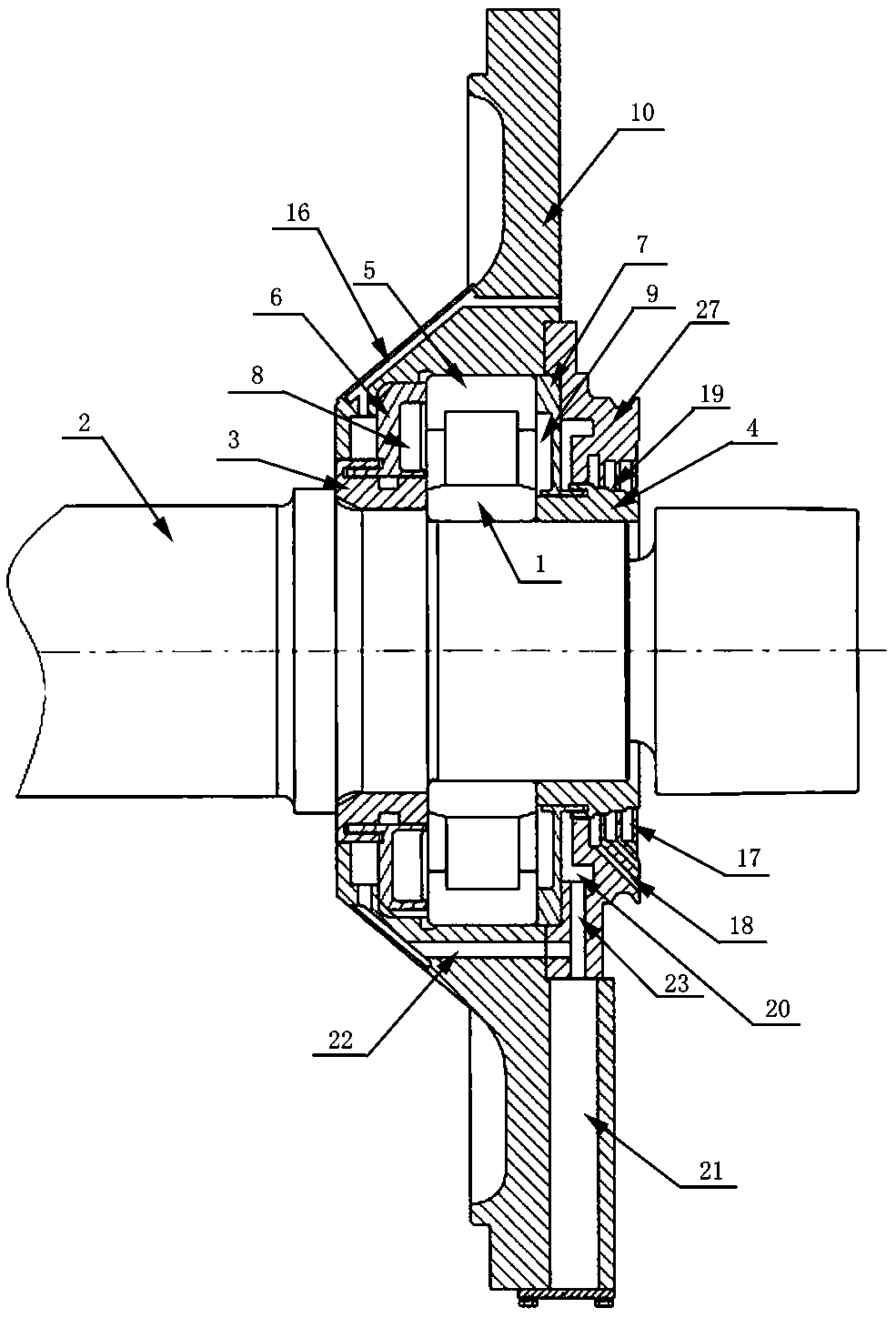

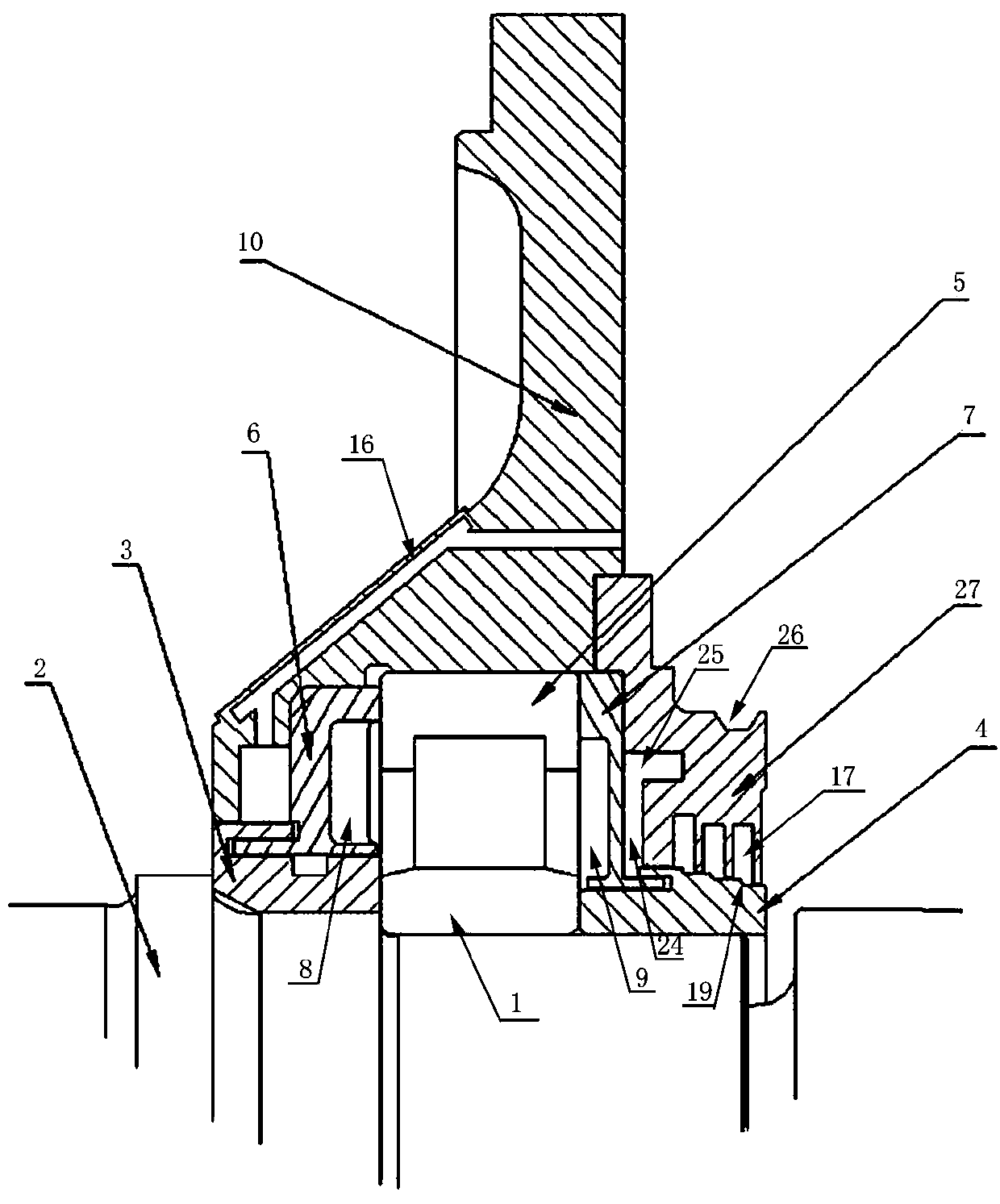

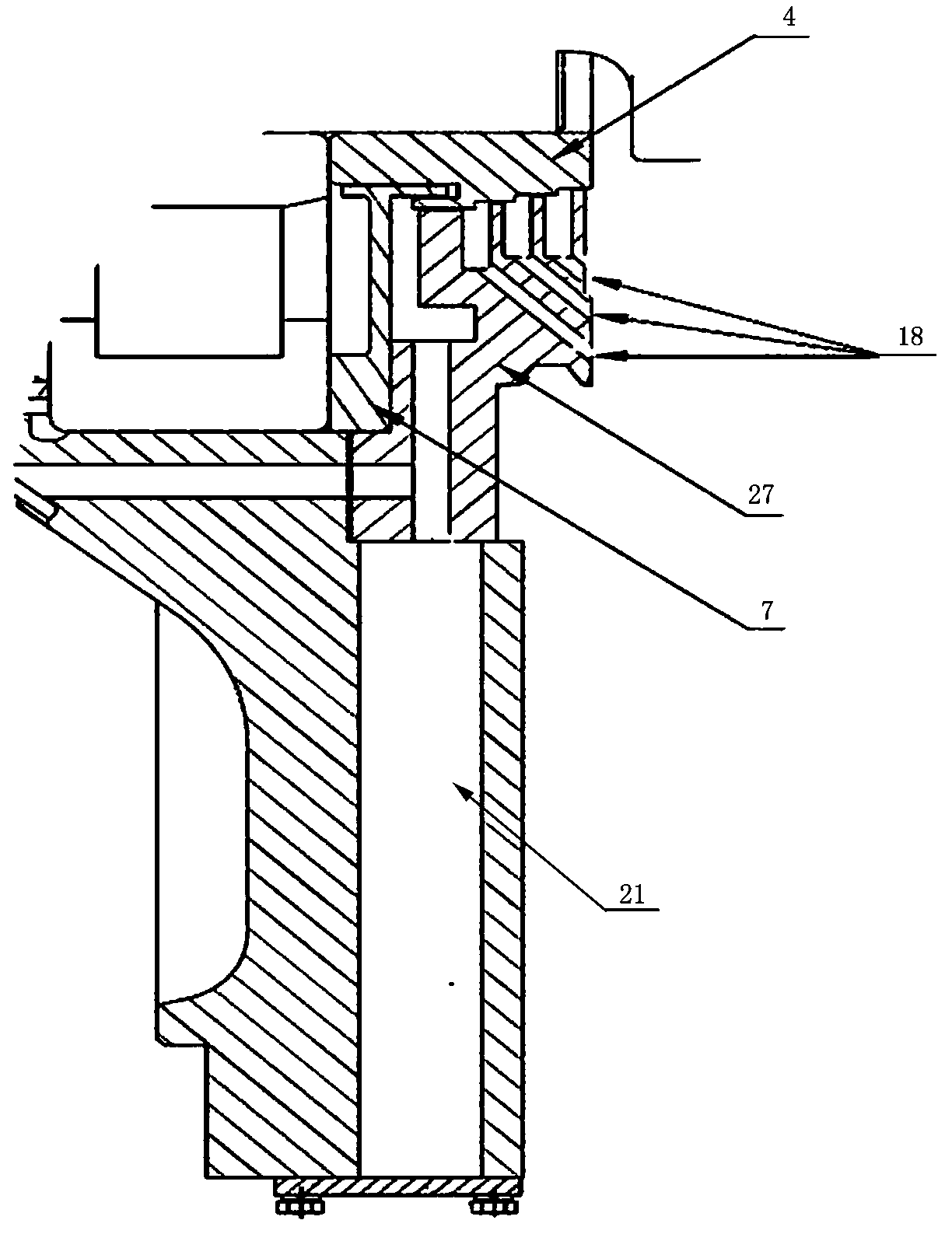

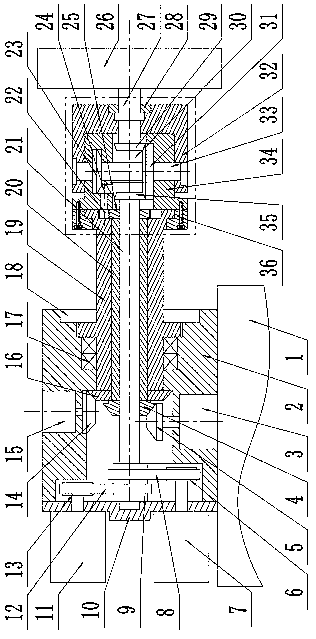

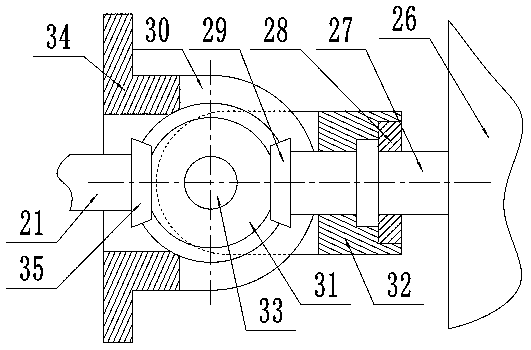

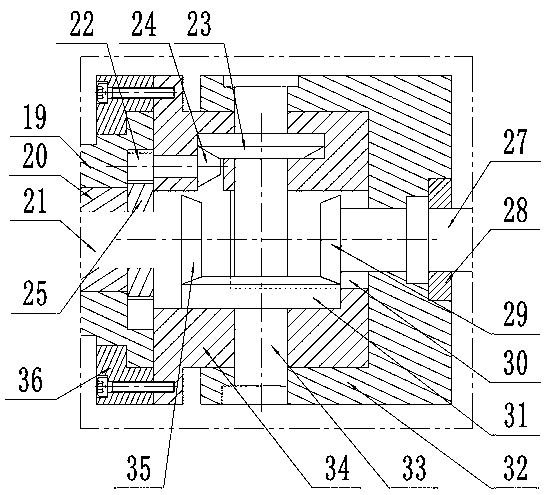

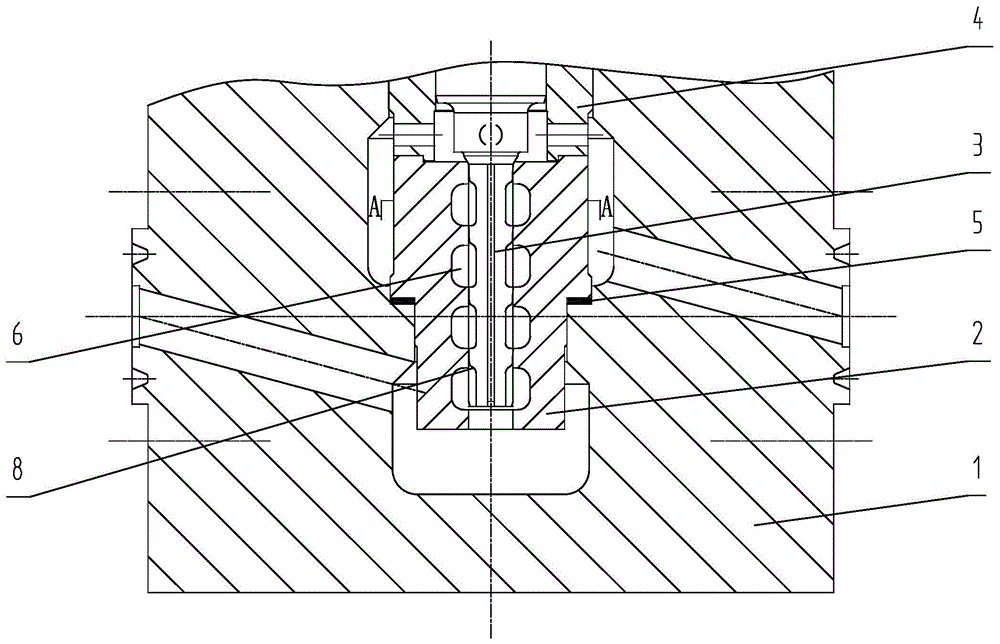

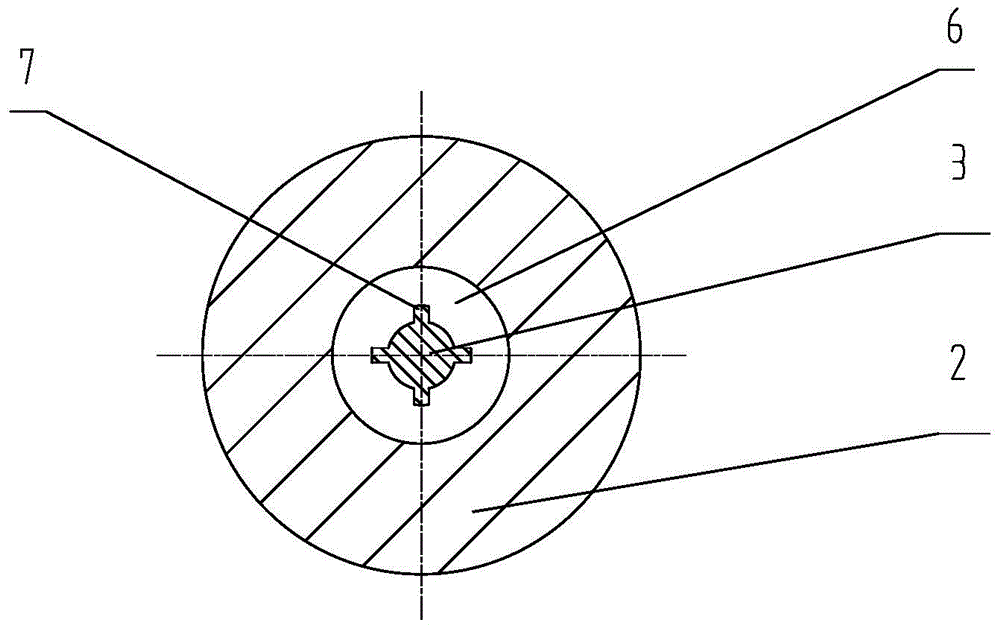

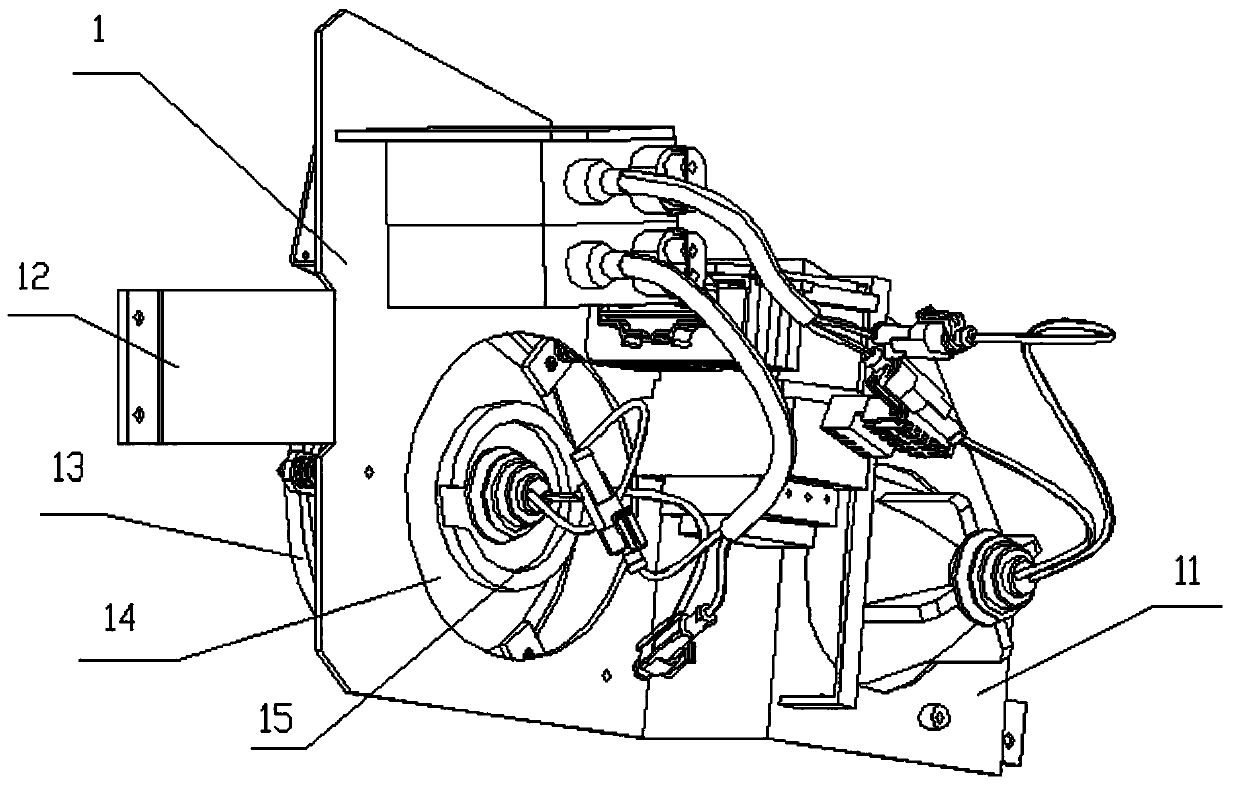

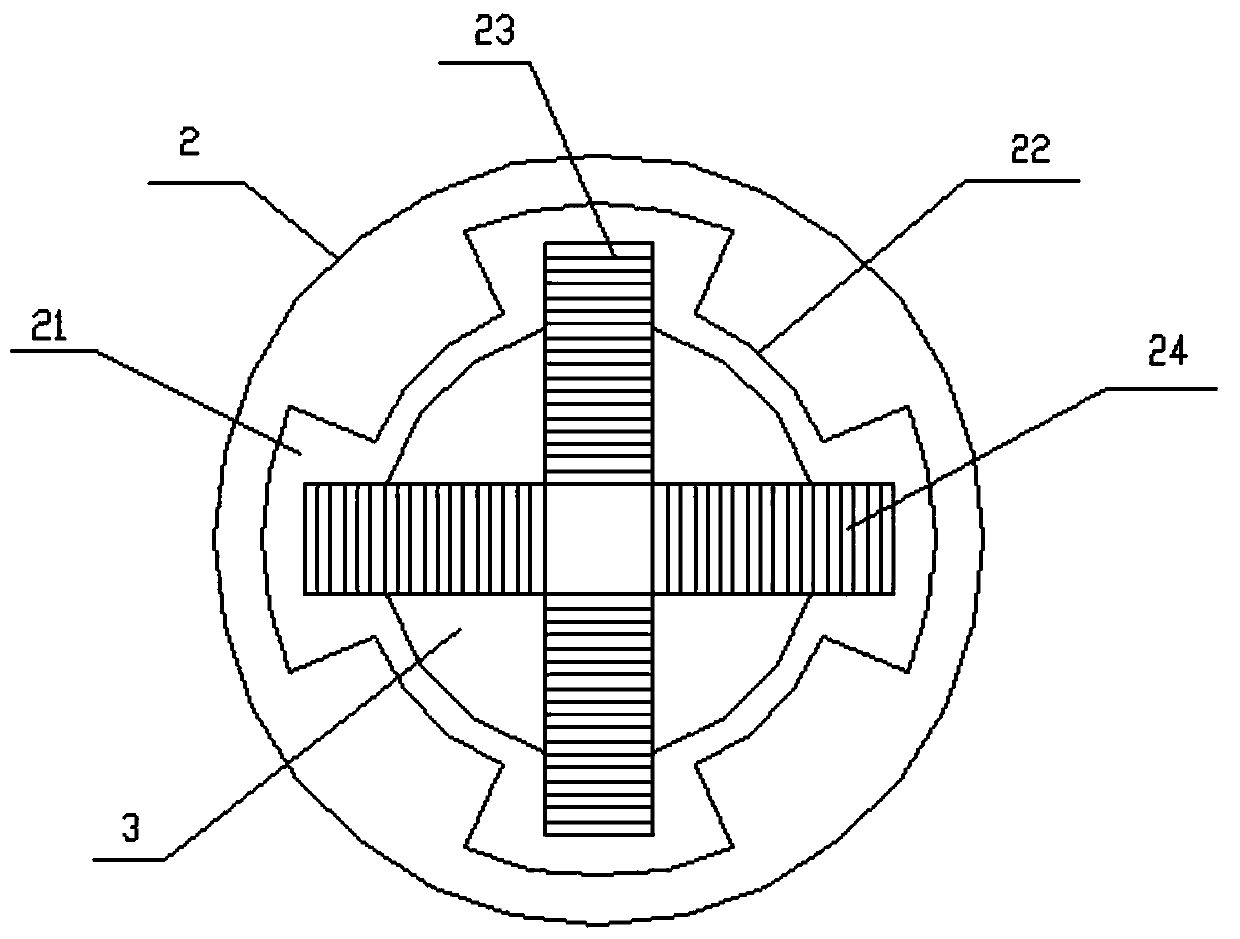

Multifunctional motor bearing sealing structure

ActiveCN108711997AMeet the sealing effectAvoid pollutionSupports/enclosures/casingsEngineeringReturn channel

The invention relates to the field of motor bearing sealing structures, in particular to a multifunctional motor bearing sealing structure. The objective of the invention is to solve problems that thecurrent bearing sealing structure has single function, lubricating grease in a bearing chamber easily enters the motor and oil mist in a gear box easily enters the bearing chamber. The structure is characterized in that a two-stage stair hole which is gradually expanded from the interior to the exterior is arranged in the end cover; an air charging channel is arranged in the end cover and two ends of the air charging channel communicates with the external atmosphere and a second through hole; an outer bearing cover is arranged to be adjacent to the outer side of the bearing cover; multiple annular grooves are arranged in the inner ring of the outer bearing cover; each annular groove communicates with an oil returning channel led to the gear box; annular stairs are arranged on the outer ring of an outer sealing ring by corresponding to the annular grooves; an oil returning cavity is arranged in the end face of the outer bearing cover; a waste oil storage chamber communicating with theoil returning cavity, and an air discharging channel are arranged in the end cover, wherein two ends of the air discharging channel communicate with the second through hole and the oil returning cavity. According to the invention, the structure is mainly used for sealing of the motor bearing.

Owner:CRRC YONGJI ELECTRIC CO LTD

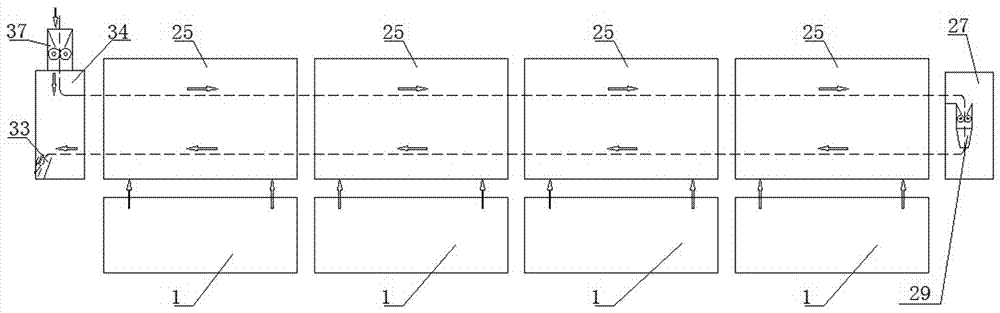

Partition wall plate steam curing method and steam curing method for concrete products

ActiveCN108407063AHigh flexibilityIncrease flexibilityCeramic shaping apparatusWater contentWall plate

The invention discloses a partition wall plate steam curing method and a steam curing method for concrete products, and relates to the technical field of concrete curing. According to the partition wall plate steam curing method, to-be-cured partition wall plates are bundled and then placed in a curing chamber, temperature control is conducted through an oil delivery pipeline for heating in the curing process, steam is introduced through a steam pipeline for humidity control, the temperature and humidity can be precisely controlled, meanwhile, adjusting and controlling of the humidity are notaffected by controlling over the humidity, and thus operation flexibility is high; and temperature control in the curing process is divided into three times of temperature increasing, the great curingeffect is obtained, finally, it is ensured that the water content on the surface of a component after natural temperature decreasing reaches the specified requirement, repeated detecting is avoided,and the time and labor are saved. The steam curing method for the concrete products comprises the partition wall plate steam curing method, the flexibility of temperature and humidity control can be significantly improved, and the temperature control precision is high.

Owner:四川省劲腾环保建材有限公司

Mass concrete pouring construction equipment and construction process

ActiveCN113737800AReduce laborLow costHydro energy generationFoundation engineeringArchitectural engineeringPipe

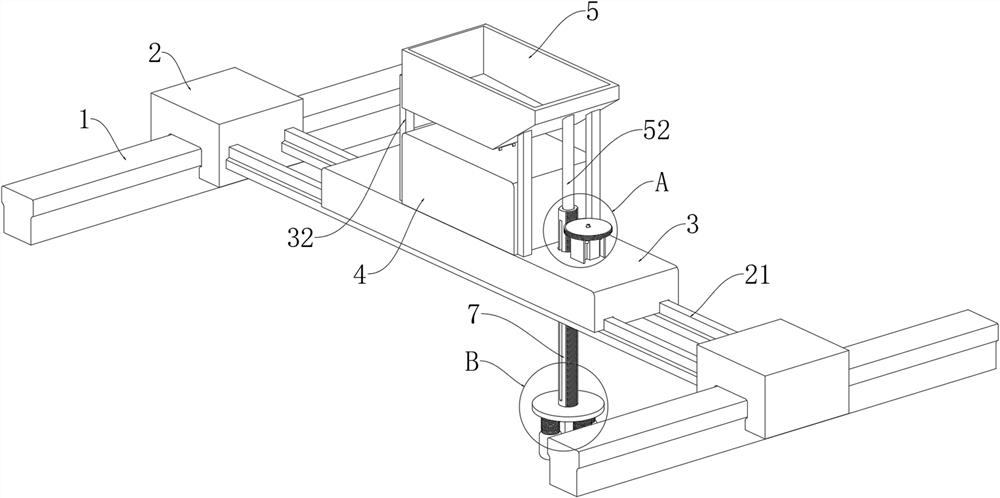

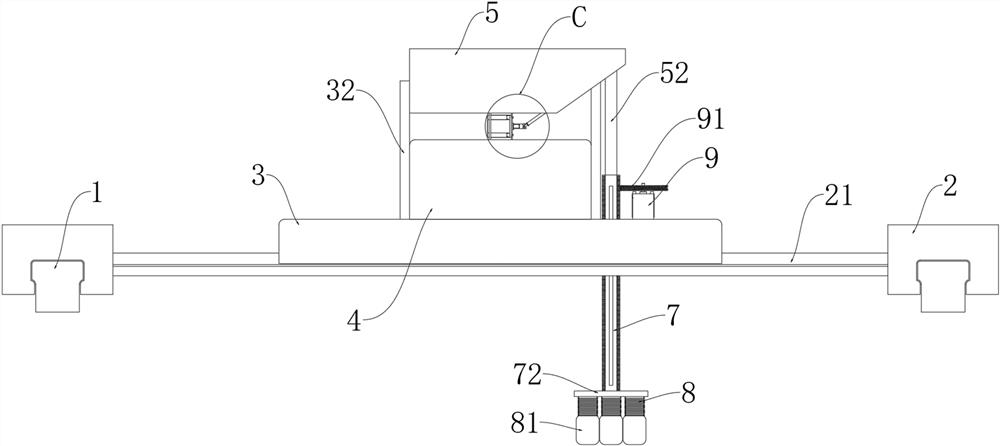

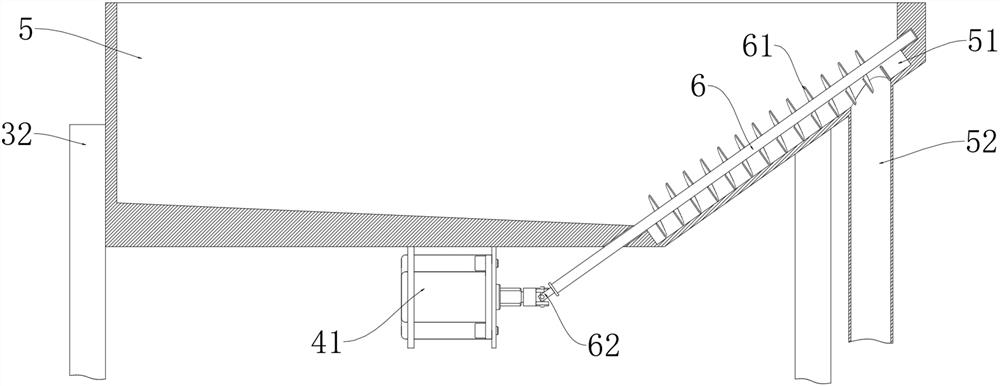

The invention discloses mass concrete pouring construction equipment. The mass concrete pouring construction equipment comprises two parallel main rails installed on the two sides of a foundation pit, each main rail is slidably provided with a main sliding block, and two secondary rails are jointly and symmetrically installed between the two main sliding blocks; the invention further discloses a mass concrete pouring construction process which comprises the following steps of anti-solidification material storage and feeding; automatically planning the travel; large-area layered pouring; performing large-area layered vibration; and automatically returning after pouring. Through cooperation of the main rail and the secondary rail, the equipment can freely move in two dimensions to achieve accurate positioning pouring, concrete solidification is avoided by arranging a spiral conveying blade in a hopper, a limiting pouring pipe and a vibrator synchronously move, the vibrator is located below the limiting pouring pipe, automatic vibrating and uniform laying are achieved during pouring, the equipment and labor cost is reduced, the construction efficiency is improved, layering is more accurate, and the layered pouring effect is improved.

Owner:南通同欧智能装备科技有限公司

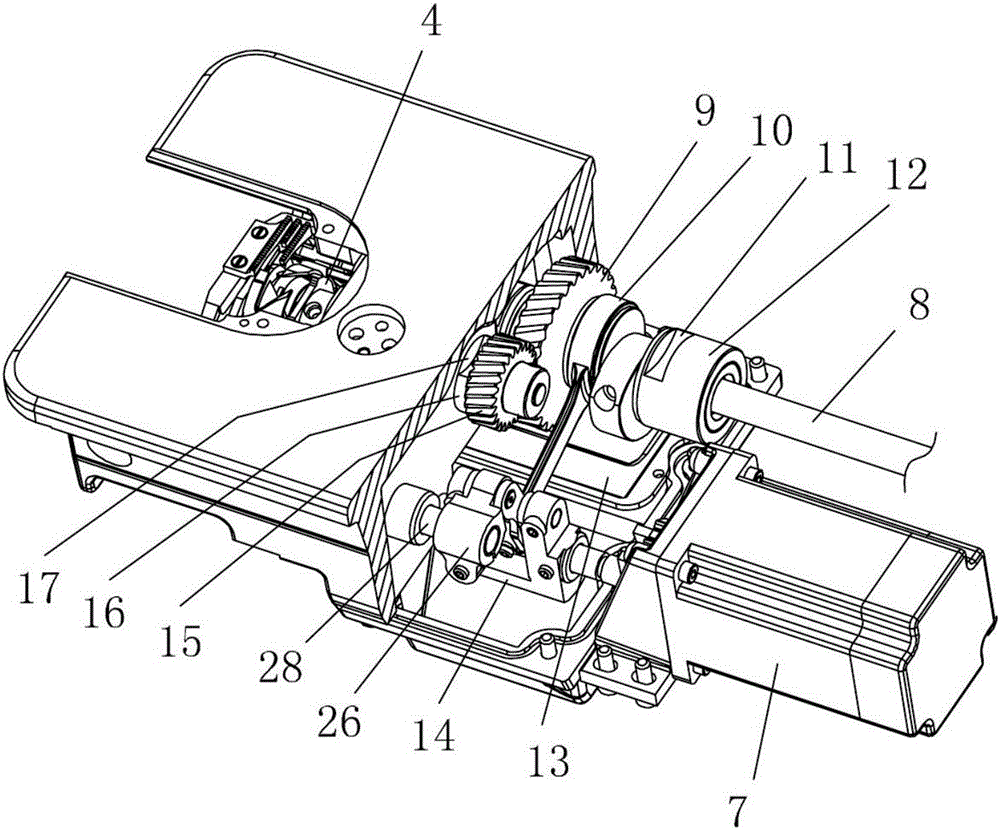

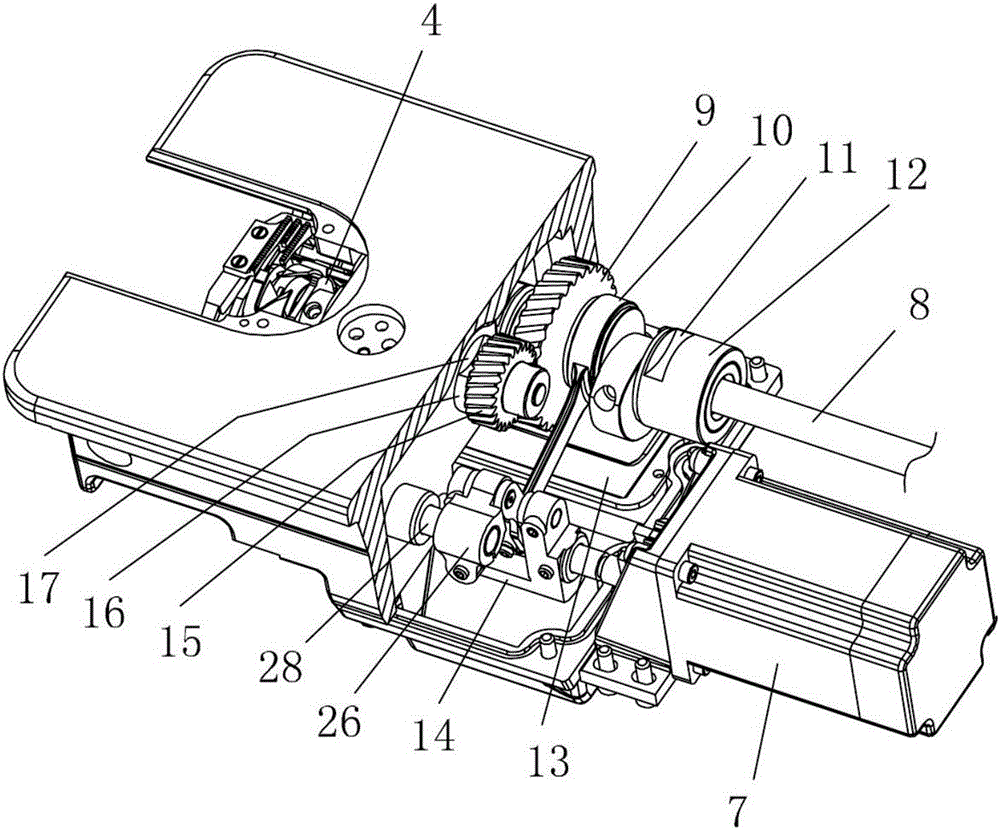

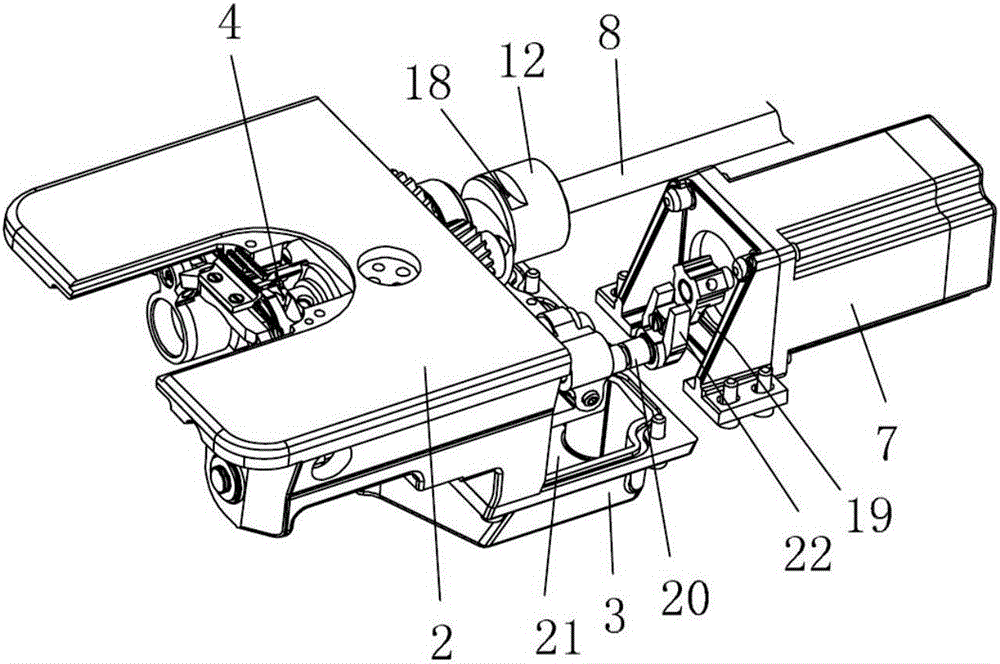

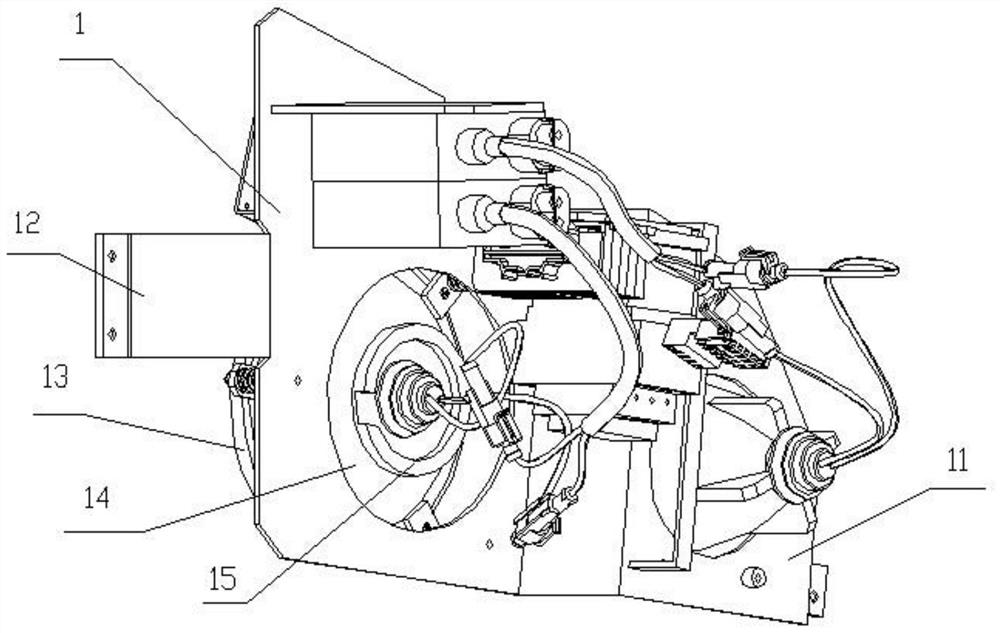

Dual-drive polishing device for machinery manufacturing

InactiveCN108568751AEffective regulationMeet the needs of different surface grindingGrinding drivesGrinding machinesDrive shaftGear wheel

The invention discloses a dual-drive polishing device for machinery manufacturing. The dual-drive polishing device comprises a moving mechanism, a drive box, a motor I, a driven gear I, a driving gearI, a driving belt pulley I, a polishing motor I, a drive belt I, a driven belt pulley, an end cover, a polishing motor II, a drive belt II, a driving belt pulley II, a driving gear II, a motor II, adriven gear II, a bearing, a fixing cover I, an outer sleeve, an inner sleeve and a drive shaft. The dual-drive polishing device is reasonable and simple in structure, low in production cost and convenient to mount; the motor II and the motor I are arranged, the polishing angle of a grinding wheel can be effectively adjusted, the requirement of polishing of different surfaces of the same part is met, and the polishing efficiency and accuracy are improved. The motor I and the motor II are both stepping motors, so that accurate control through the prior art is facilitated. A transition end surface gear is arranged and can effectively transfer power of polishing motors to the grinding wheel, and the adjustment of different angles of the grinding wheel is not affected.

Owner:JINING UNIV

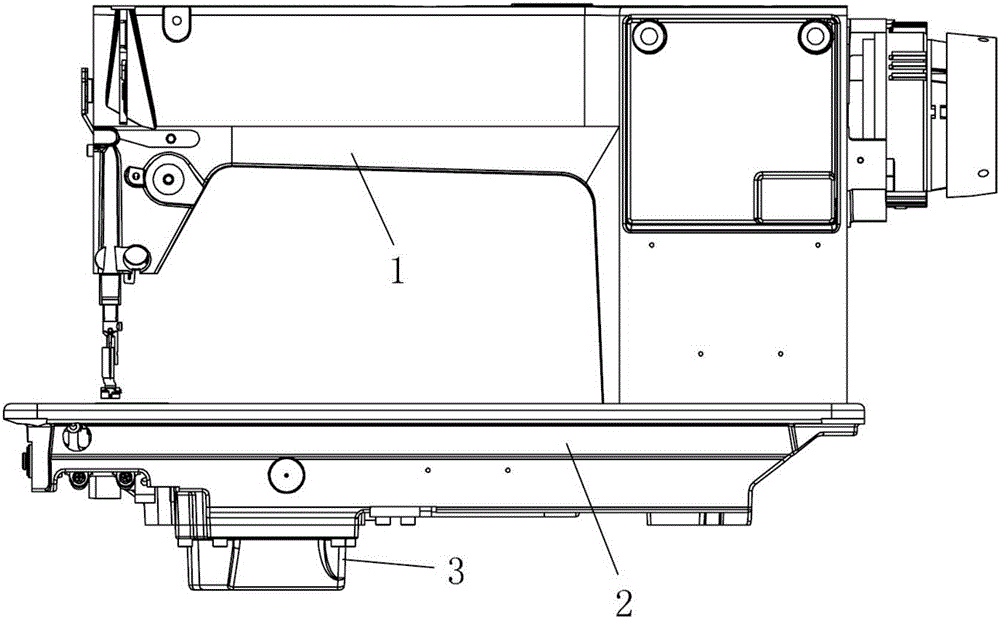

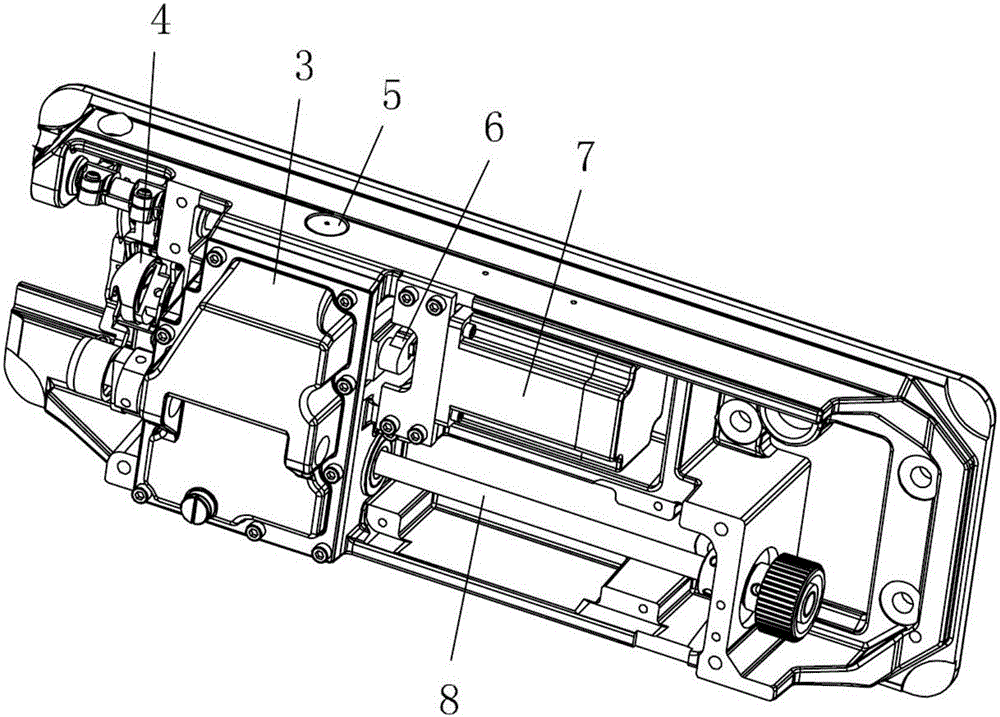

Lubrication system of sewing machine

ActiveCN106757853AOutstanding and Beneficial Technical EffectsAggregate Demand DecreasesLubrication/cooling devicesGear transmissionLubrication

The invention belongs to the technical field of sewing machines and particularly relates to a lubrication system of a sewing machine. A transmission chamber is arranged on the lower portion of a sewing machine shell, a feed lifting rock shaft drives a rotating hook shaft to rotate through a second transmission mechanism, an oil box is mounted on the lower portion of the transmission chamber, an oil storage cavity is arranged in the oil box which seals the lower end face of the transmission chamber, the second transmission mechanism is in gear transmission, a driving gear mounted on the feed lifting rock shaft meshes with a driven gear mounted on the rotating hook shaft, an oil storage tray is mounted in the transmission chamber and on the lower side of the driving gear, and the lower portion of the driving gear is immersed with oil fluid when a specific quantity of oil fluid is accumulated in the oil storage tray. The lubrication system of the sewing machine has the advantages that the oil fluid in the oil storage tray can be thrown out when the driving gear rotates at a high speed and sputtered on the inner walls of parts and components and the transmission chamber, so that lubrication oil is better in atomization effect in the transmission chamber, all the components can be lubricated effectively, and operating noise is reduced greatly.

Owner:ZHEJIANG DUMA SEWING MACHINE

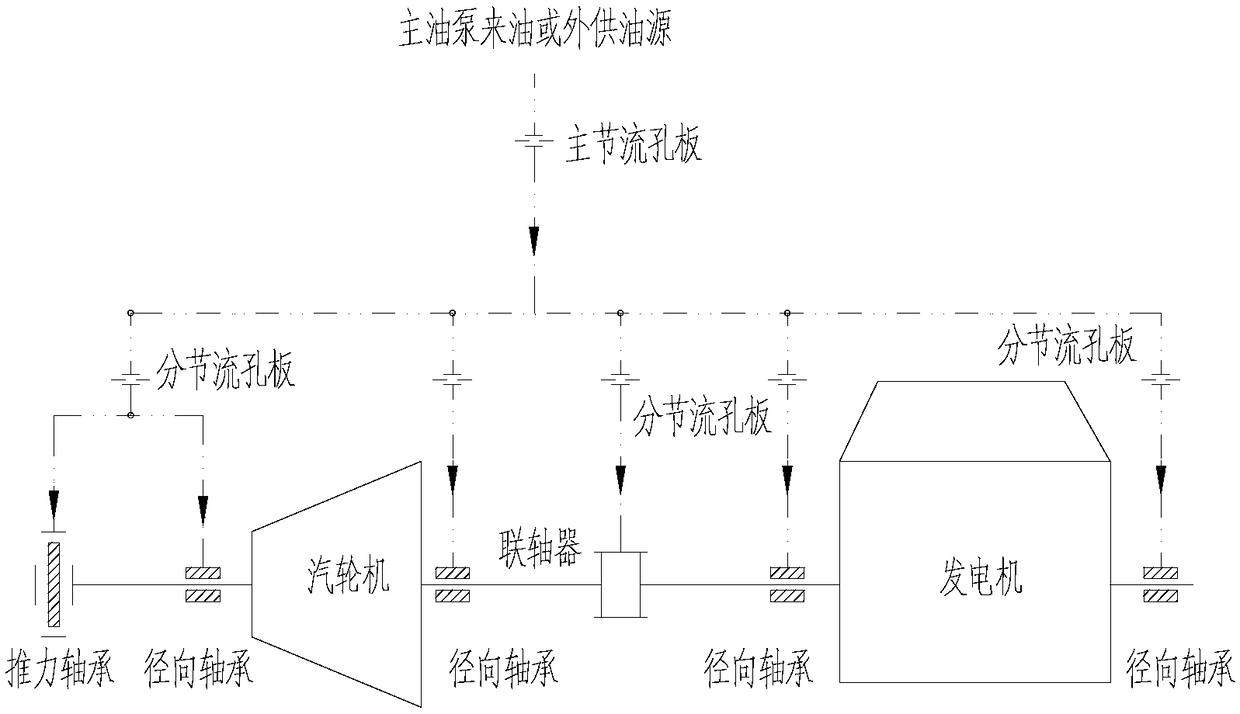

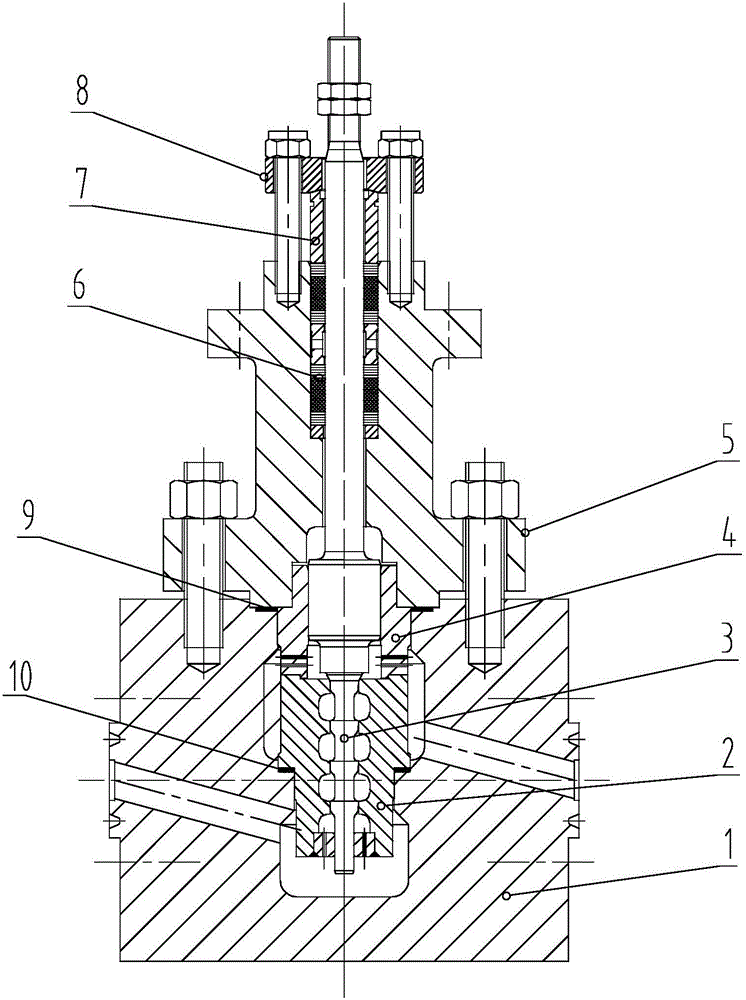

Self-operated multi-stage throttling lubricating oil pressure regulating valve

PendingCN109268551ASimple structureReduce volumeValve members for absorbing fluid energyEqualizing valvesSpool valveEngineering

The invention relates to a self-operated multi-stage throttling lubricating oil pressure regulating valve. A casing is composed of an inner casing body and an outer casing body, the outer casing bodyis provided with an inlet and outlet flange and a leakage opening pipe joint, and the bottom of the inner casing body is provided with an inclined hole to make an outlet and a cavity in the bottom ofthe inner casing body communicated; a sliding valve is sleeved with the casing, a flange extending from a bottom cover is sleeved with the casing and forms a limiting part for the downward movement ofthe sliding valve, a flange extending from the upper side of the sliding valve is sleeved with a spring, and the upper portion of the spring sleeves a flange extending from a gland; the upper end ofthe casing is provided with an upper cover, and a boss with an external thread and an internal thread hole extends from the upper cover; a screw rod is screwed into the internal thread hole of the boss of the upper cover and presses the gland, and the upper portion of the screw rod is fastened and fixed to the upper cover through a nut. By means of the valve, multi-stage throttling of lubricatingoil can be achieved in a limited space, and the vibration noise of a pipeline is effectively reduced; the downstream lubricating oil pressure can be adjusted online, and setting in debugging tests isfacilitated; the damping property of the valve can effectively relieve the drastic fluctuation of regulating the downstream lubricating oil pressure.

Owner:SHANGHAI MARINE EQUIP RES INST

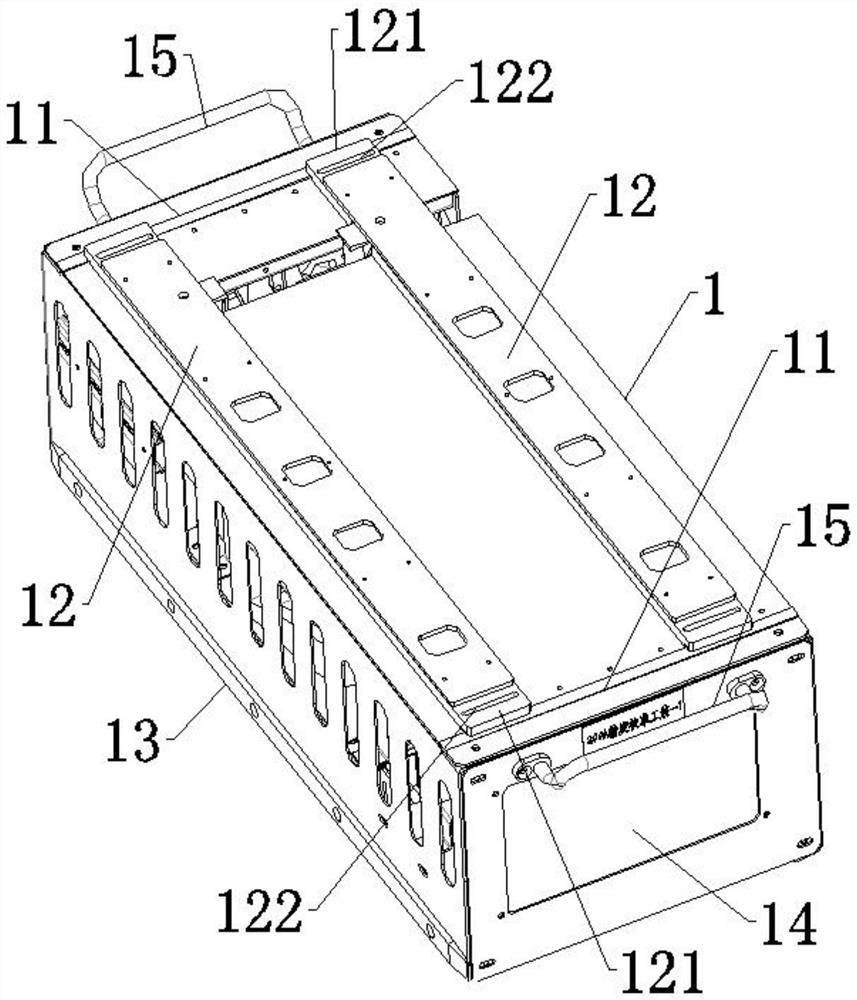

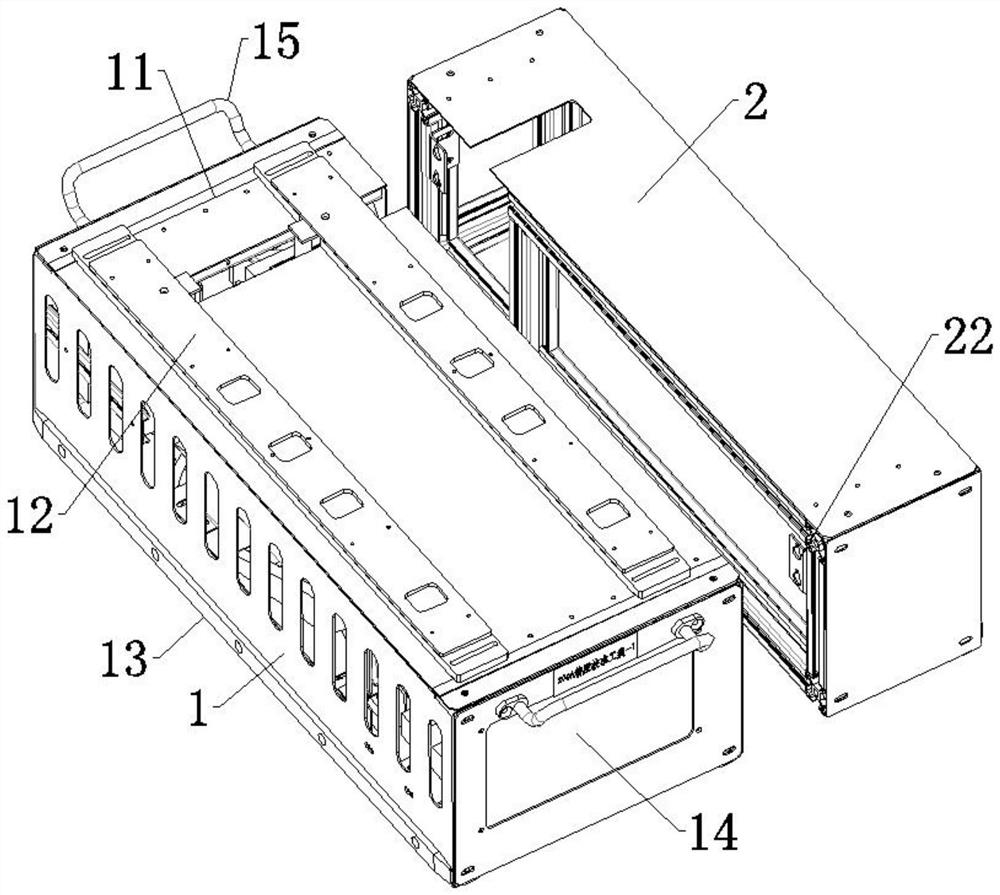

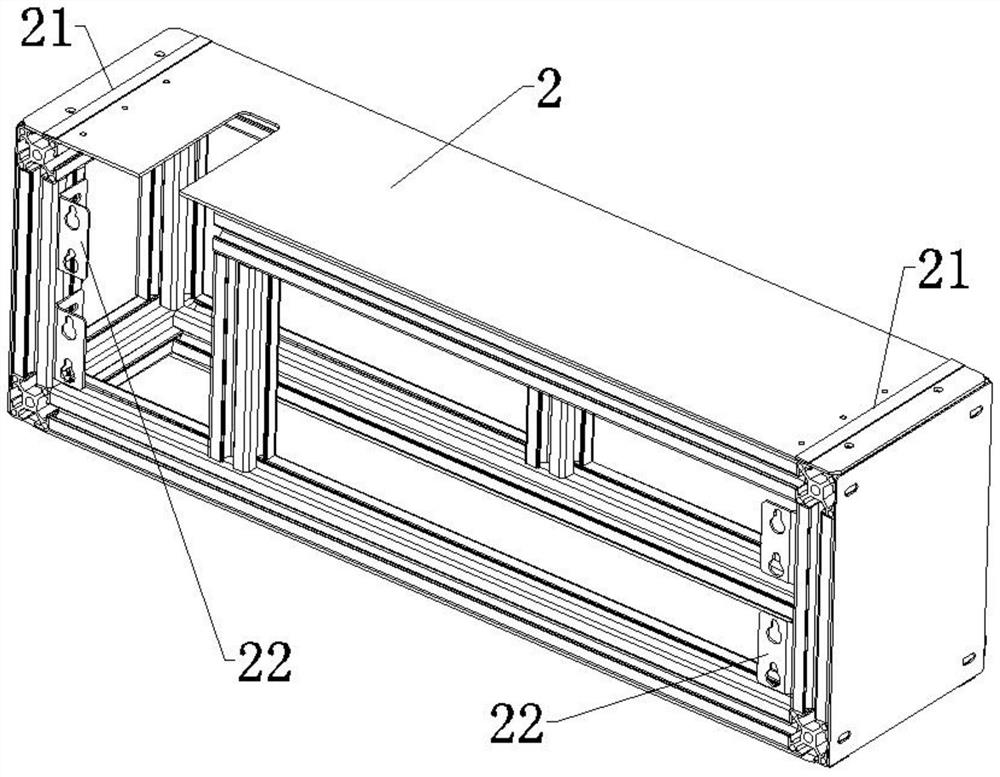

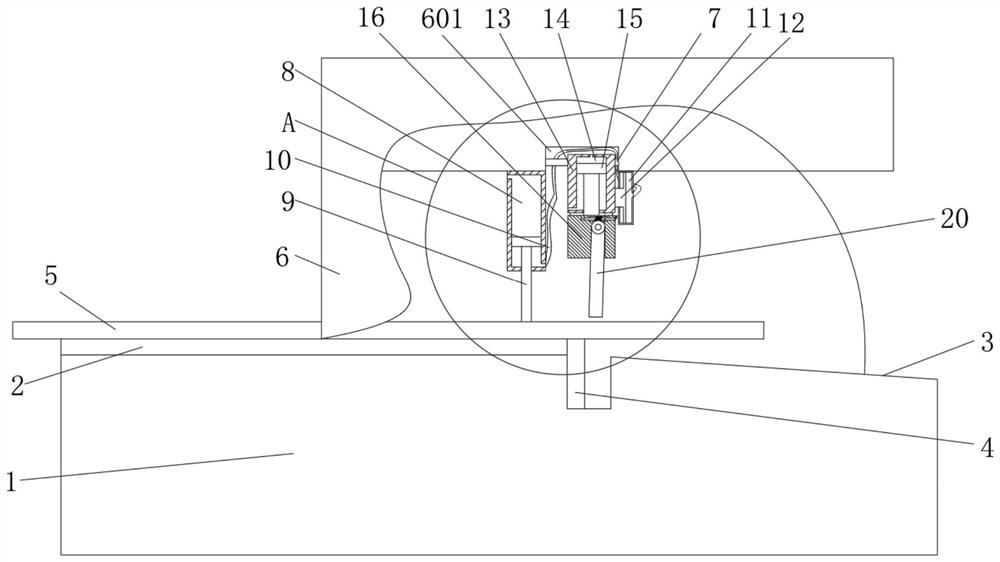

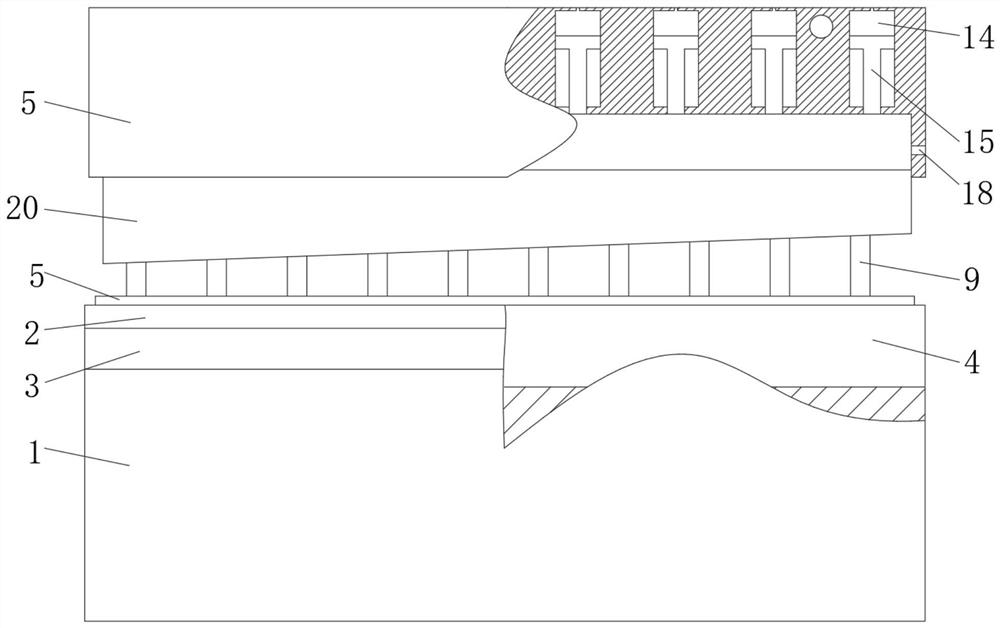

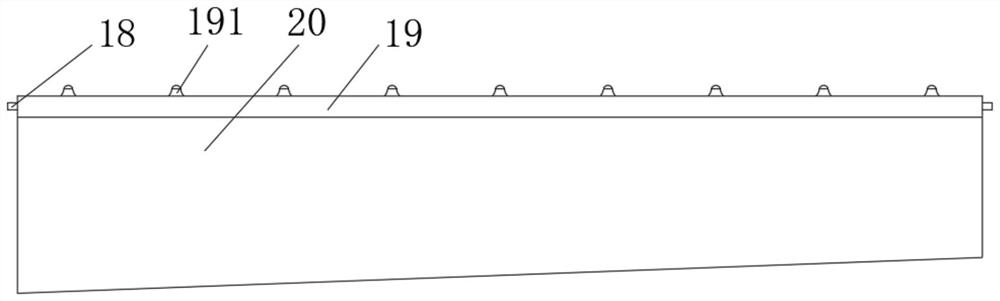

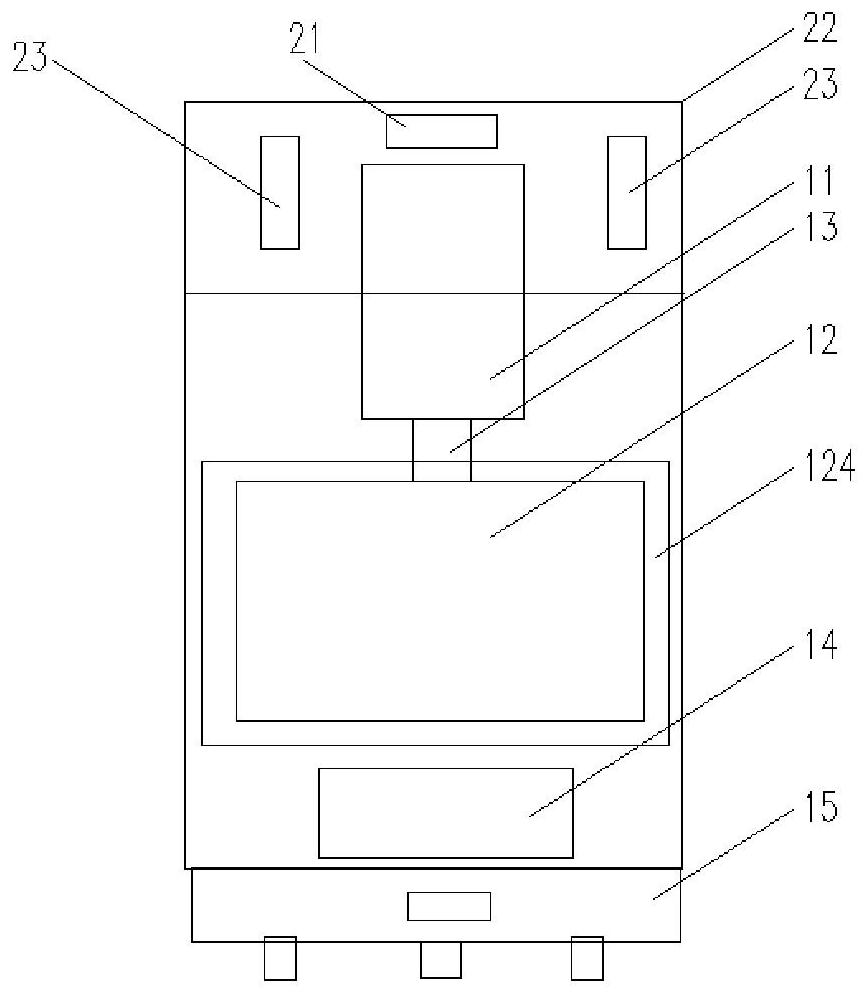

Battery cell precision calibration tool for formation and capacity grading equipment

PendingCN113013495AEasy access to electricityCompact structureFinal product manufactureSecondary cells charging/dischargingWireless routerData connection

The invention discloses a battery cell precision calibration tool for formation and capacity grading equipment in the technical field of formation and capacity grading calibration, and the tool comprises a tool box body which is a fully-closed ventilated hollow box body, wherein two calibration graduated scales and two electrode plates are respectively arranged at the top of the tool box body; the two calibration graduated scales are arranged on the two opposite side edges of the top of the tool box body in parallel, quick insertion and quick connection can be achieved when the square battery cell formation and capacity grading equipment is detected, electricity taking and data connection of devices of the equipment can be completed only by aligning the device with an electricity taking port of the formation and capacity grading equipment and pushing the device in, so the installation is very convenient. And the wireless router and the universal meter are integrated in the device, so the device can more conveniently detect the data of the formation and capacity grading equipment, and all detection devices are cooperatively connected and mounted in an integral protection box body, so that the circuit is more regular.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

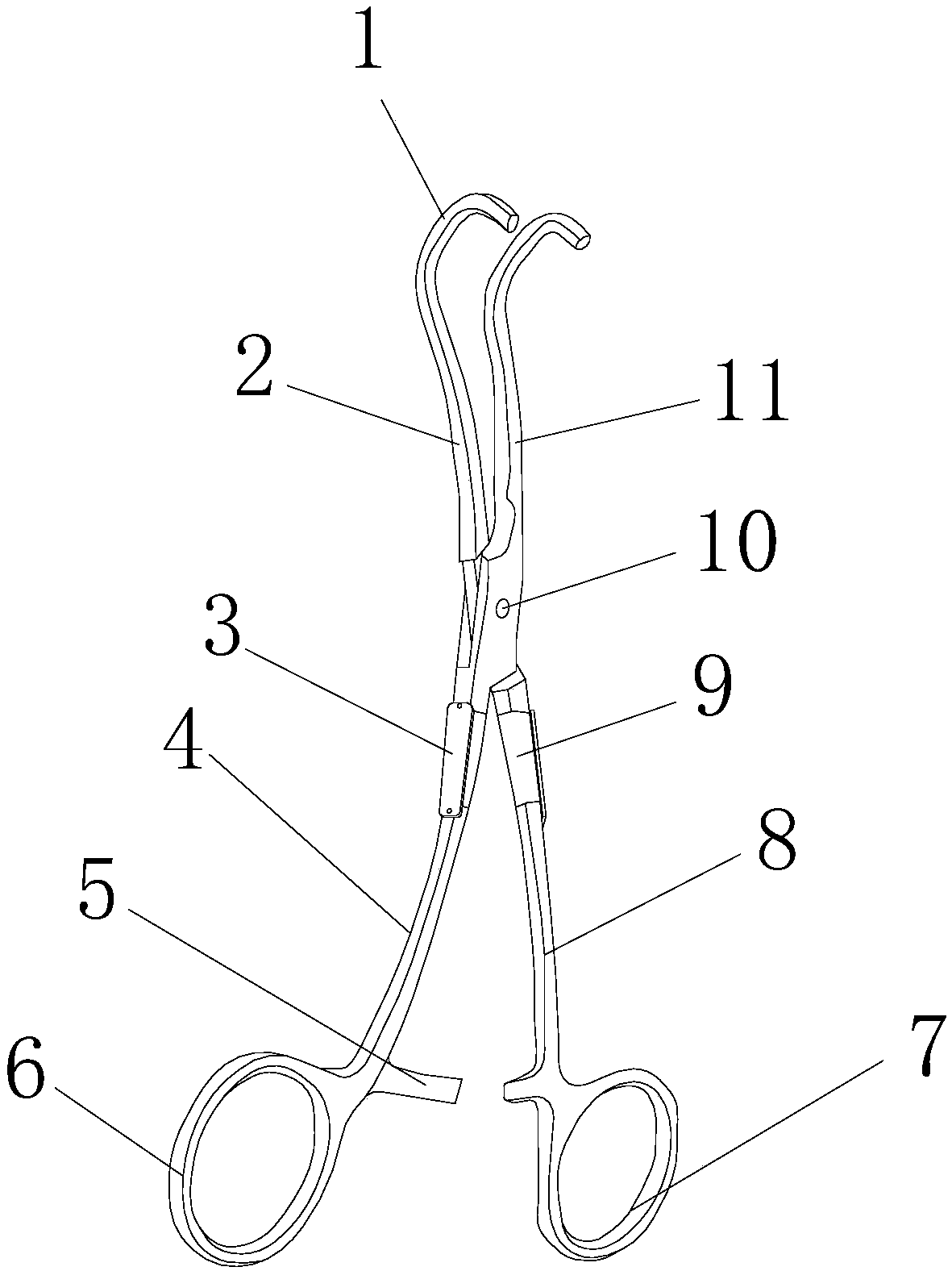

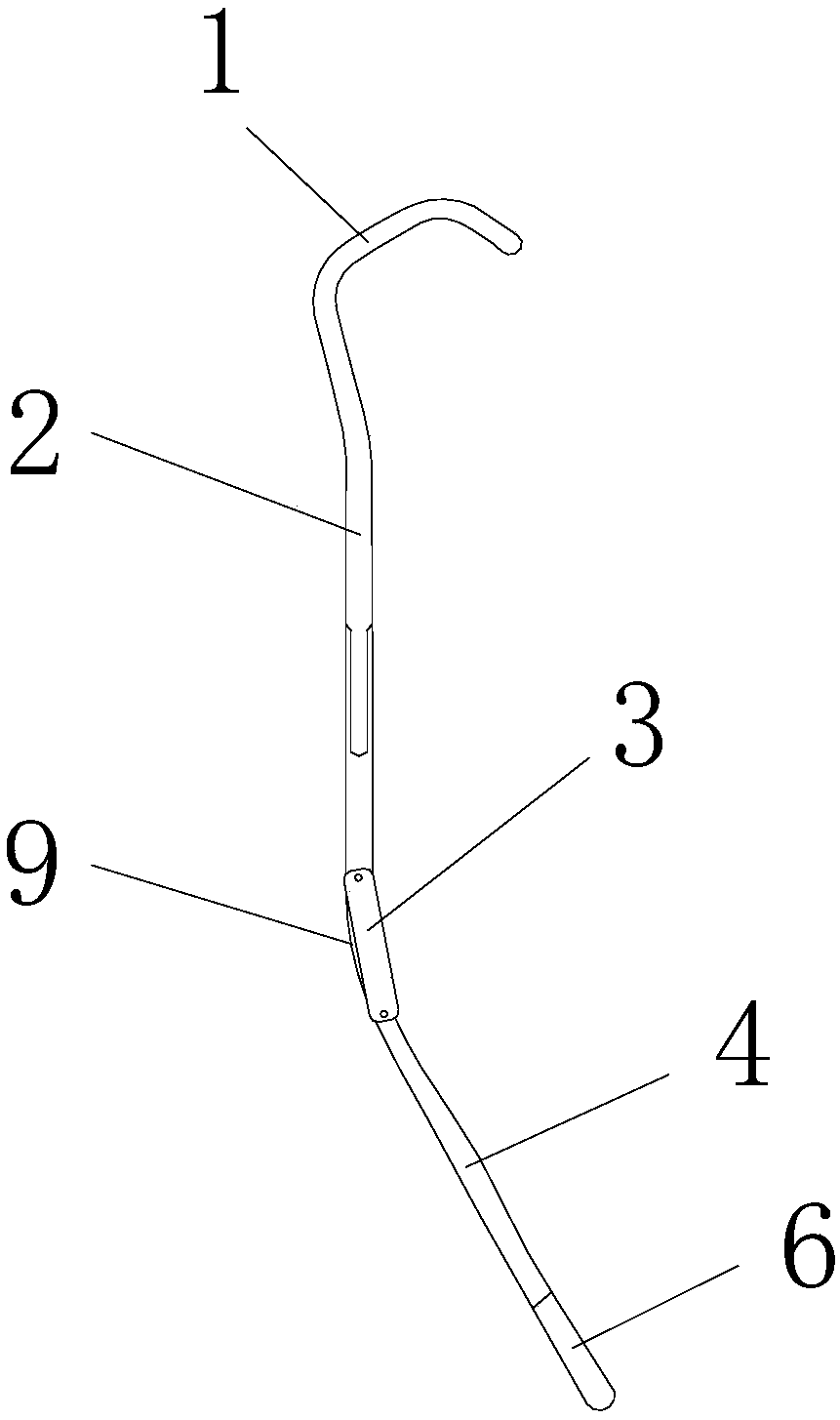

Iliac vein lateral forceps for urinary and proctology department

The invention discloses iliac vein lateral forceps for a urinary and proctology department. The iliac vein lateral forceps comprise a bent head, a lateral plate, a first forceps handle, a second forceps handle and solid aluminum alloy flexible pipes, wherein a first finger ring is arranged at one end of the first forceps handle, a first forceps head is arranged at the other end of the first forceps handle, the first forceps handle and the first forceps head are fixedly connected through the solid aluminum alloy flexible pipe, a lateral plate is further arranged on one side of the first forcepshandle and one side of the first forceps head, a second finger ring is arranged at one end of the second forceps handle, and a second forceps head is arranged at the other end of the second forceps handle. According to the iliac vein lateral forceps disclosed by the invention, the forceps heads and the forceps handles are connected through the solid aluminum alloy flexible pipes; furthermore, thelateral plate is arranged on the sides of the forceps heads and the sides of the forceps handles, and the two ends of the lateral plate are respectively in rotary connection with the forceps heads and the forceps handles through pin shafts; thus, the use of the lateral forceps has certain strength, and angle adjustment among the forceps handles and the forceps heads is not affected. Therefore, the iliac vein lateral forceps disclosed by the invention is suitable for operations at different positions and has the advantage of more simpleness and more convenience in use.

Owner:成都三木行新能源科技有限公司

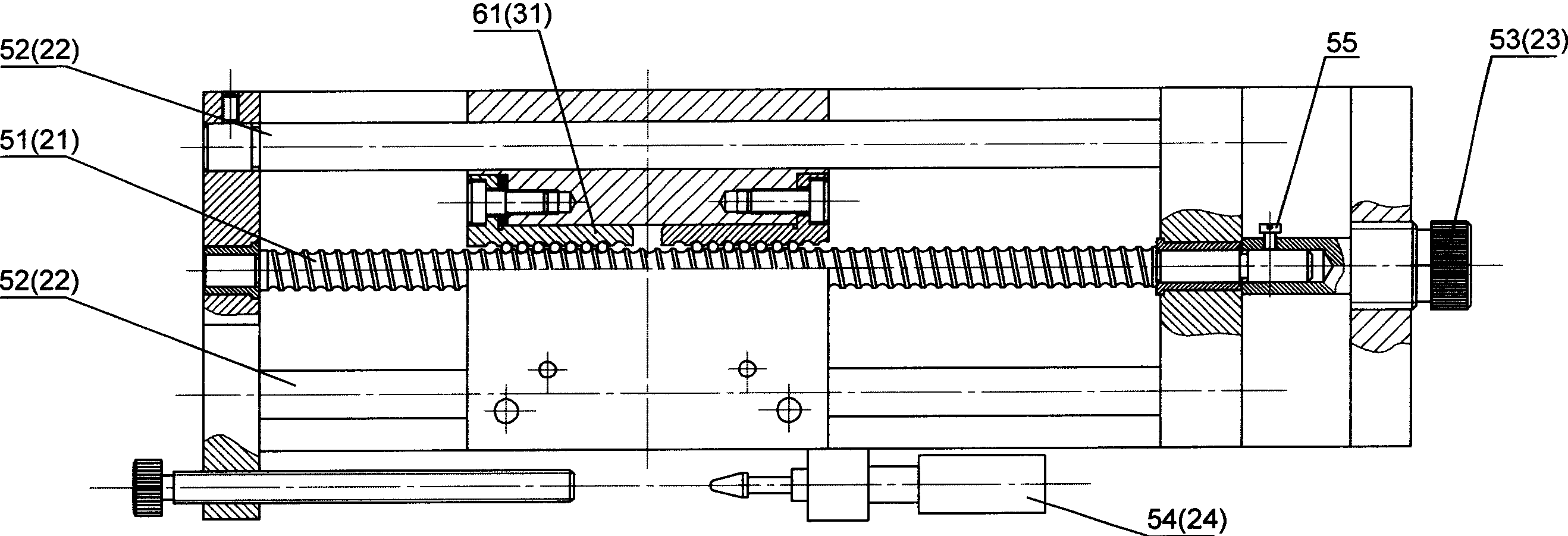

Self-adjusting plate shearing machine

InactiveCN113210699AAccurate self-regulationAvoid Angular AutoReply SituationsShearing machinesShearing machine accessoriesOil canMetal machining

The invention relates to the technical field of metal machining, and discloses a self-adjusting plate shearing machine. The self-adjusting plate shearing machine comprises a material pressing cylinder, a moving body and a gap cylinder are installed on one side of the material pressing cylinder, a material pressing rod is movably sleeved with the material pressing cylinder, a series connection pipe is fixedly connected to an outlet in the bottom end of the material pressing cylinder, a gap adjusting rod is movably sleeved with the gap cylinder, and a protruding block is fixedly connected to the center of the bottom of the left side of the gap cylinder. Through the designed material pressing cylinder, the series connection pipe and the gap cylinder, when the material pressing cylinder presses a plate, oil can be synchronously supplied to the gap cylinder through the downward pressing distance, so that the moving body with an upper blade can move proportionally according to the thickness of the plate, and the blade gap can be accurately and automatically adjusted according to the thickness of the plate; and meanwhile, through an designed adjusting lead screw, when the blade gap is self-adjusted, the adjusting lead screw can be influenced by movement of the moving body, and self-adjustment of the shearing angle of the upper blade is completed.

Owner:原旭东

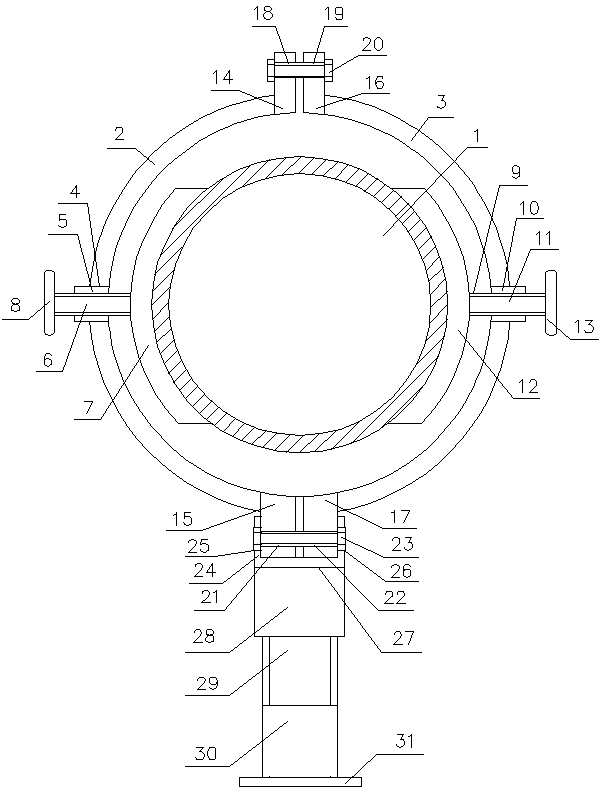

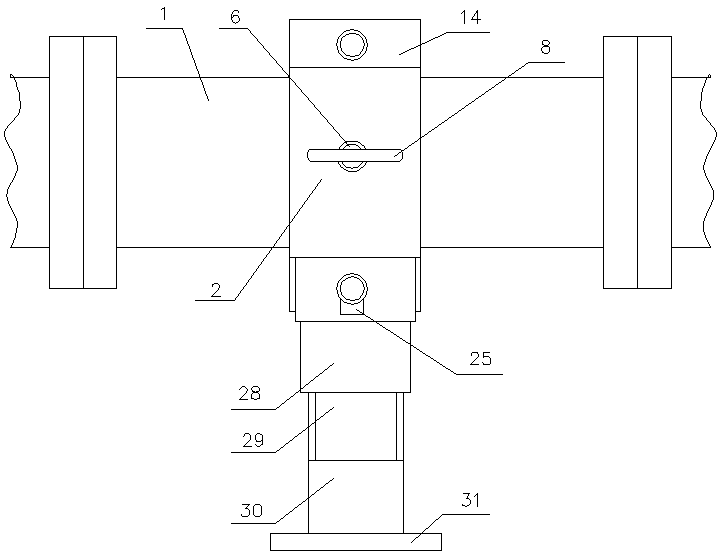

Novel oilfield flow string fixing device and use method

InactiveCN110469716AEasy to useStrong and safe supportPipe supportsAgricultural engineeringEngineering

Provided are a novel oilfield flow string fixing device and a use method. The novel oilfield flow string fixing device comprises an oilfield flow string, and the oilfield flow string is provided witha front arc-shaped pinch plate and a rear arc-shaped pinch plate. The oilfield flow string is buckled by the front arc-shaped pinch plate and the rear arc-shaped pinch plate. Clearance exit between the front arc-shaped pinch plate and the oilfield flow string and between the rear arc-shaped pinch plate and the oilfield flow string. A front threaded hole is formed in the front arc-shaped pinch plate, and a front threaded sleeve is welded to the front threaded hole. The front threaded sleeve is connected with a front threaded rod, and a front fastening arc clamping plate is welded to the front end of the front threaded rod. A front adjusting rod is welded to the rear end of the front threaded rod, dan a rear threaded hole is formed in the rear arc-shaped pinch plate. A rear threaded sleeve is welded to the rear threaded hole, and the rear threaded sleeve is connected with a rear threaded rod. A rear fastening arc clamping plate is welded to the front end of the rear threaded rod. A rearadjusting rod is welded to the rear end of the rear threaded rod. The oilfield flow string is clamped and fixed by the front fastening arc clamping plate and the rear fastening arc clamping plate. Thenovel oilfield flow string fixing device is used for fixing the oilfield flow string.

Owner:刘丽

Lubricating oil atomizing system of sewing machine transmission chamber

InactiveCN106521837AOutstanding and Beneficial Technical EffectsAggregate Demand DecreasesLubrication/cooling devicesOil absorptionSewing machine

The invention relates to a lubricating oil atomizing system of a sewing machine transmission chamber. The lubricating oil atomizing system is characterized in that the transmission chamber is arranged on the lower portion of a sewing machine shell, an oil box is mounted on the lower portion of the transmission chamber, an oil storage cavity is arranged in the oil box, and the oil box seals the lower end face of the transmission chamber; a feed lifting rock shaft and a rotating shuttle shaft extend into the transmission chamber; a drive gear is mounted on the feed lifting rock shaft, a driven gear is mounted on the rotating shuttle shaft, and the drive gear meshes with the driven gear; an oil storage support plate is mounted in the transmission chamber on the lower side of the drive gear, and the lower portion of the drive gear is immersed by oil when a certain amount of oil is stored in the oil storage support plate; an oil absorption channel is arranged in the transmission chamber, and the lower end of the oil absorption channel is immersed by oil when a certain amount of oil is stored in the oil storage cavity. The lubricating oil atomizing system has the advantages that the oil is thrown out by the drive gear and splashes to various parts and the inner wall of the transmission chamber, and accordingly a good atomizing effect of the lubricating oil in the transmission chamber is achieved, the parts can be effectively lubricated, and work noise is lowered greatly.

Owner:ZHEJIANG DUMA SEWING MACHINE

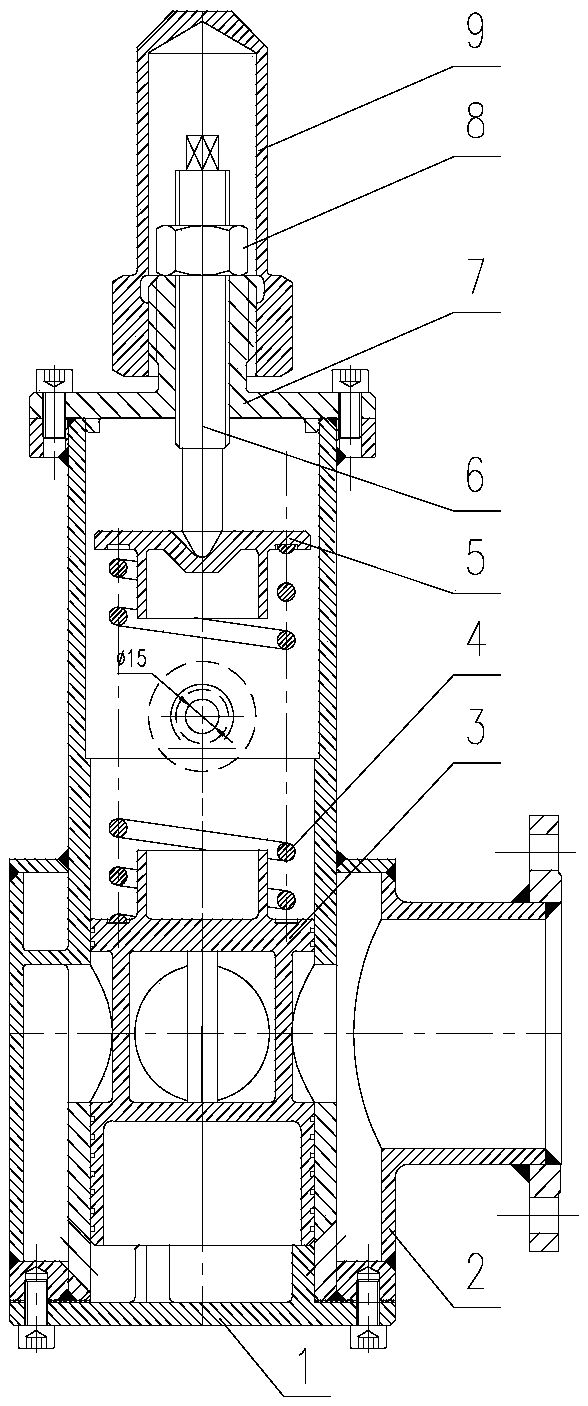

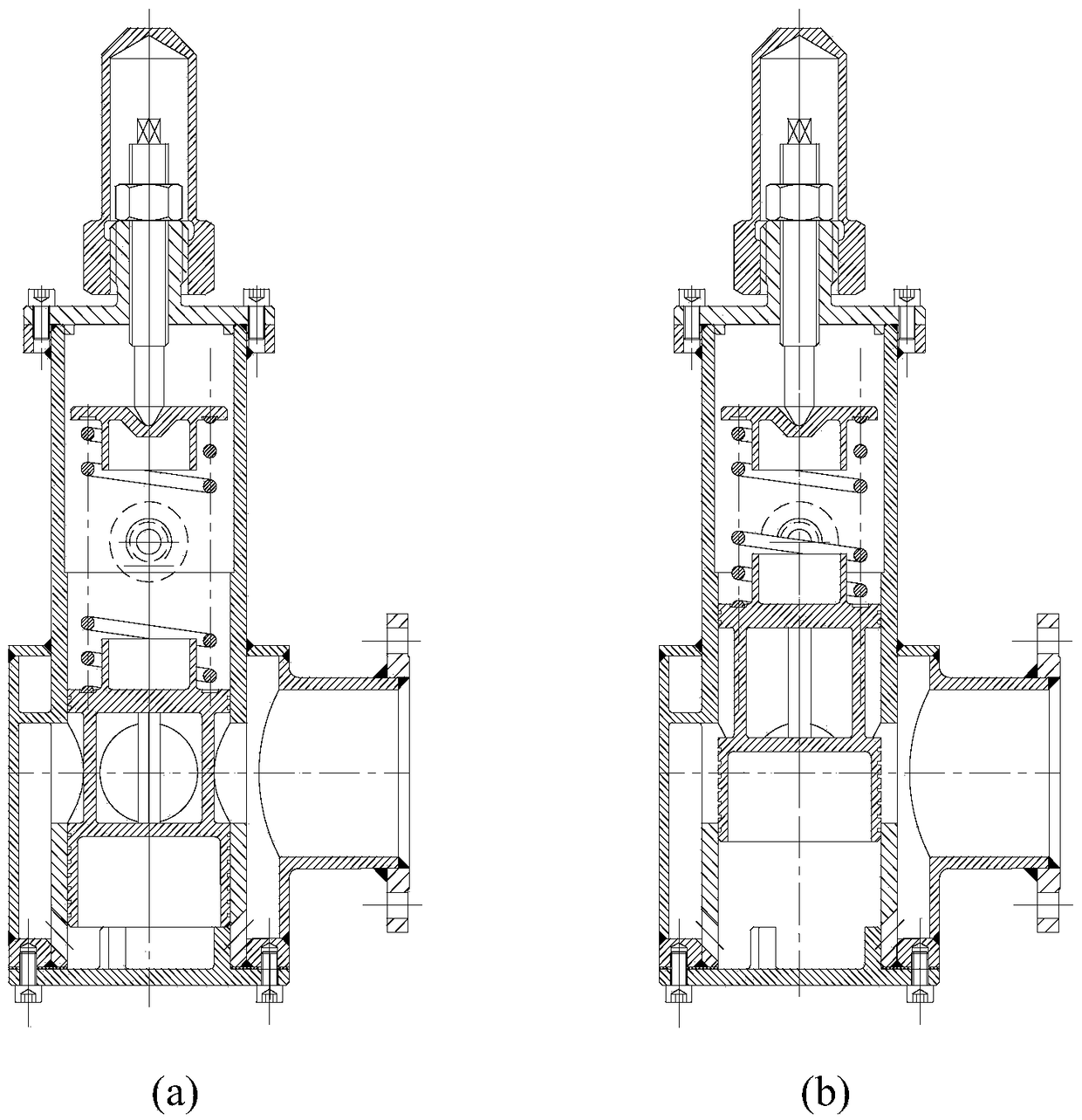

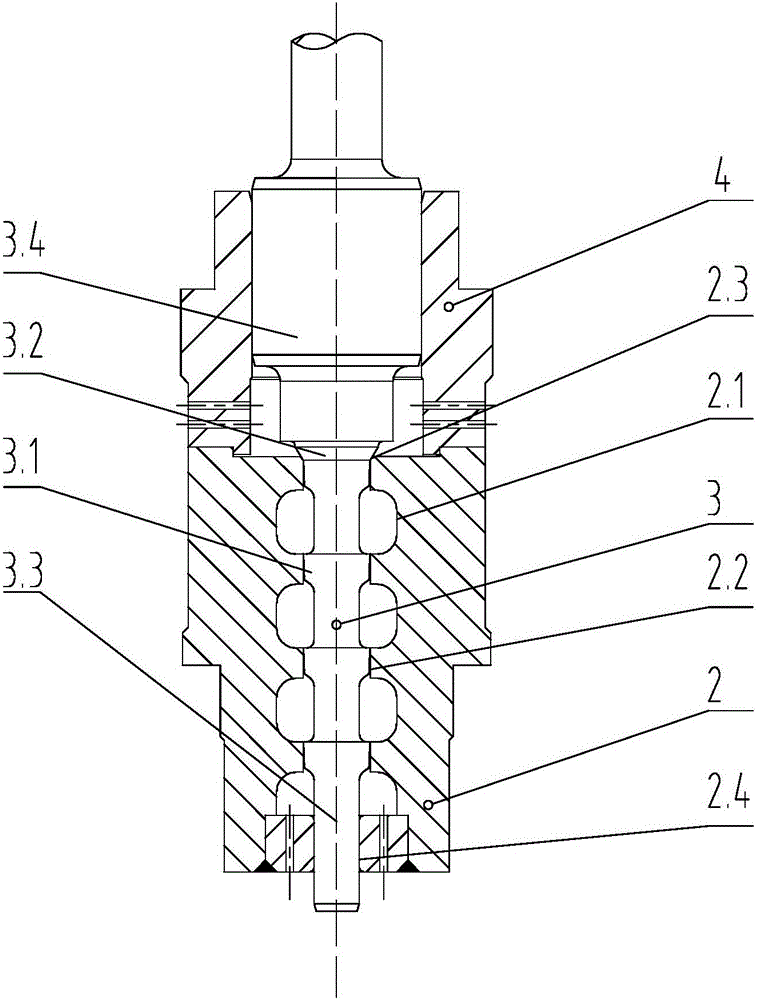

High pressure small flow string control valve

ActiveCN103591353BAvoid cavitationAvoid destructionValve members for absorbing fluid energyEqualizing valvesEngineeringControl valves

The invention relates to a regulating valve, in particular to a high-pressure and micro-flow tandem type regulating valve, and belongs to the technical field of control valves. The high-pressure and micro-flow tandem type regulating valve comprises a valve body, wherein a valve seat is arranged in the valve body, a second gasket is arranged between the valve body and the valve seat, a guide pressing sleeve is arranged at the upper end of the valve seat, the upper end of the valve body is connected with an upper cover through a bolt, the upper cover tightly presses the guide pressing sleeve and the valve seat in the valve body, and a first gasket is arranged between the valve body and the upper cover. The upper end of the upper cover is connected with a packing pressing board through a bolt. A valve element assembly is installed in the valve seat in a matched mode, the upper end of the valve element assembly penetrates through the guide pressing sleeve, the upper cover extends out of the packing pressing board, packing is arranged between the valve element assembly and the upper cover, a packing pressing cover is arranged between the packing and the packing pressing board, and the packing pressing board tightly presses the packing pressing cover and the packing. According to the high-pressure and micro-flow tandem type regulating valve, the tandem type structure is adopted, the multi-stage depressurization function is achieved, the flow velocity of media is reduced, the inner parts of the valve are protected effectively, and the noise of the valve is lowered; meanwhile, the phenomenon that as the throttling area is small when micro-flow regulation is performed, the valve is blocked can be avoided; the valve element assembly is of a double-guide structure and is prevented from bending and deforming, the regulation stability of the valve is improved, and the service life of the valve is prolonged.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

A device for adjusting the angle of led lights

Owner:YANYANG LAMP SET TIANCHANG CITY

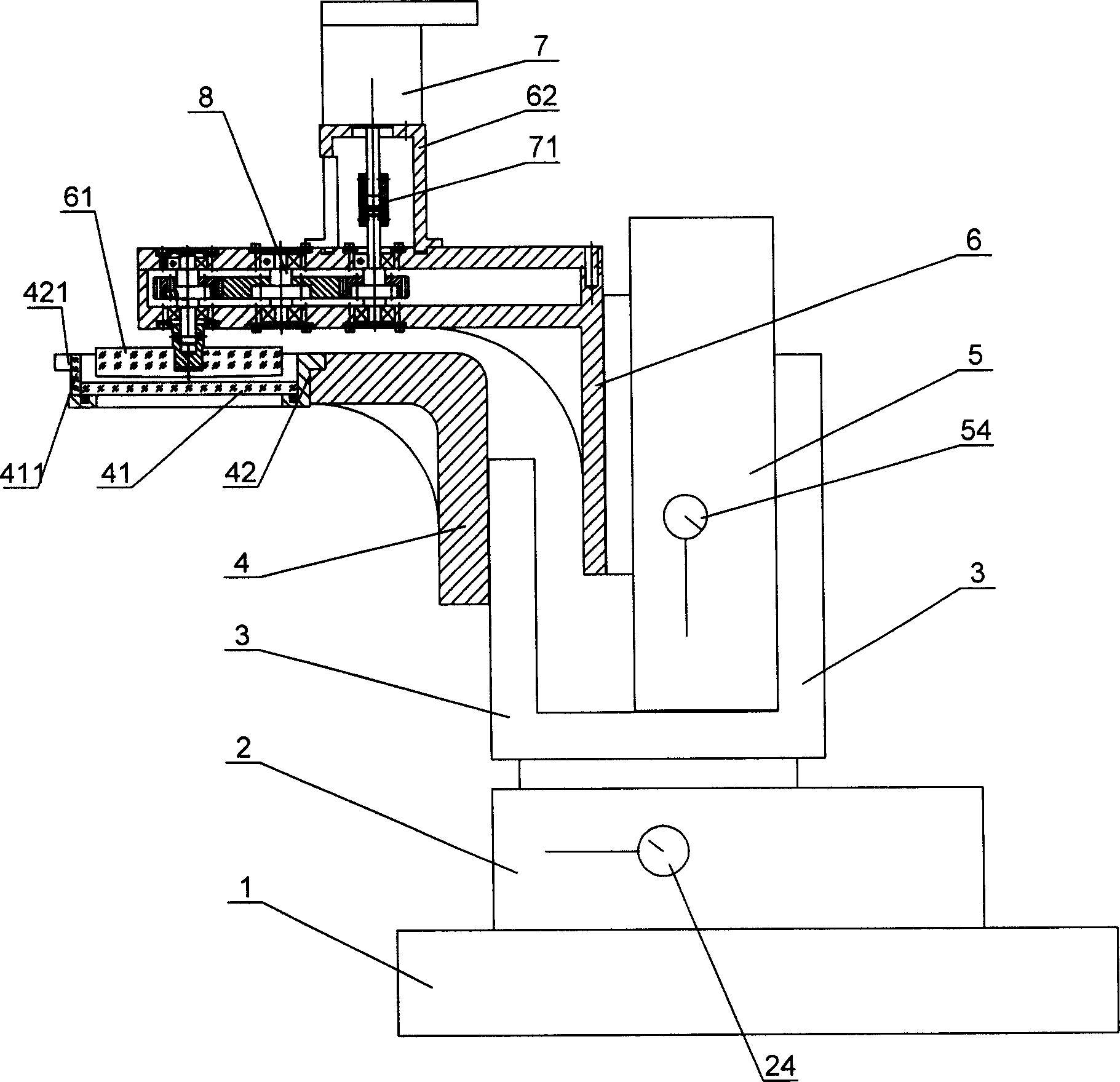

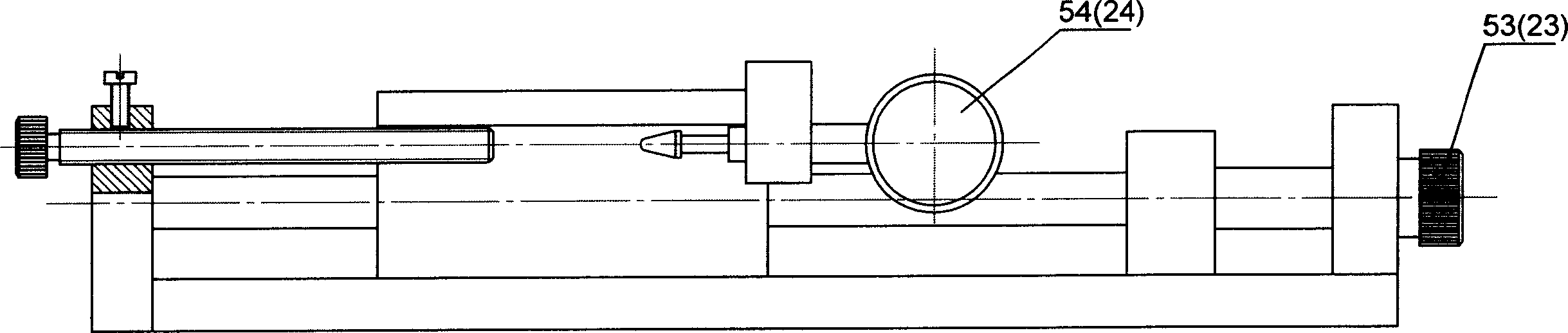

Microscopically-observable cone-plate shear field generator

InactiveCN1866006AEasy to observe in real timeEasy to disassembleBiological testingShear fieldMicroscope

The disclosed generator for cone plate shearing field comprises: a base with a vertical drive device, a U-shape frame with bottom connected to the drive device, a frame for fill-liquid utensil on one side of U-shape frame with another side fixed another vertical drive device, a cone plate frame with back end connected to last drive device and its front end fixed a cone plate opposite the utensil, and a motor with gear on cone plate frame. This invention is fit to different microscope and brings convenience to user.

Owner:BEIHANG UNIV

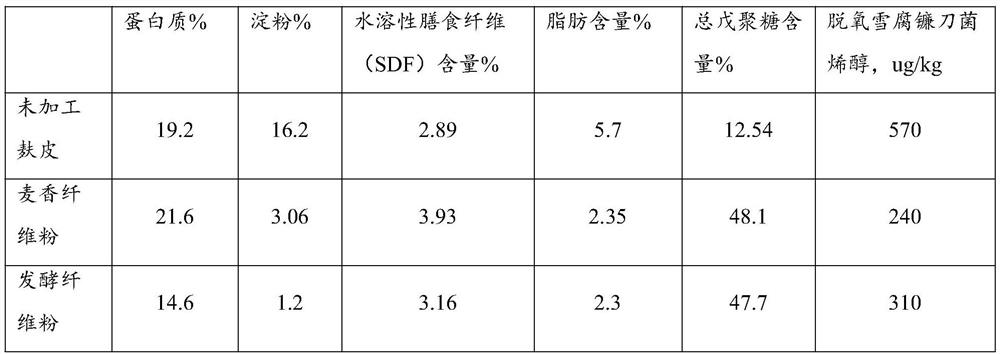

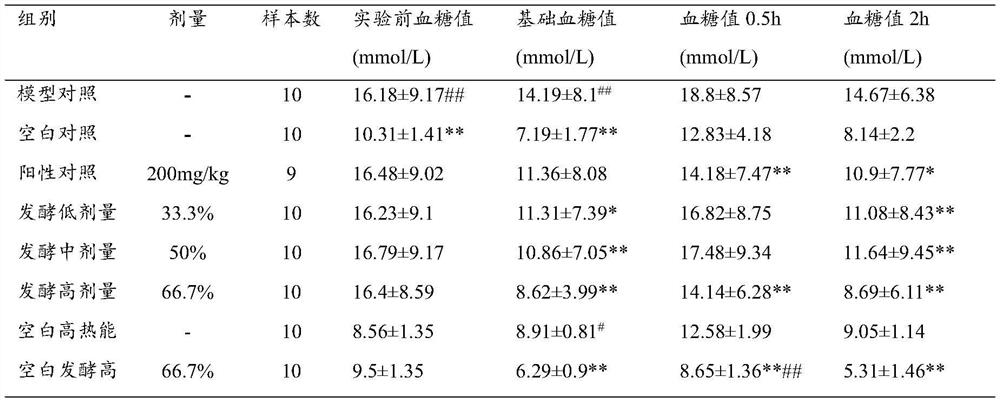

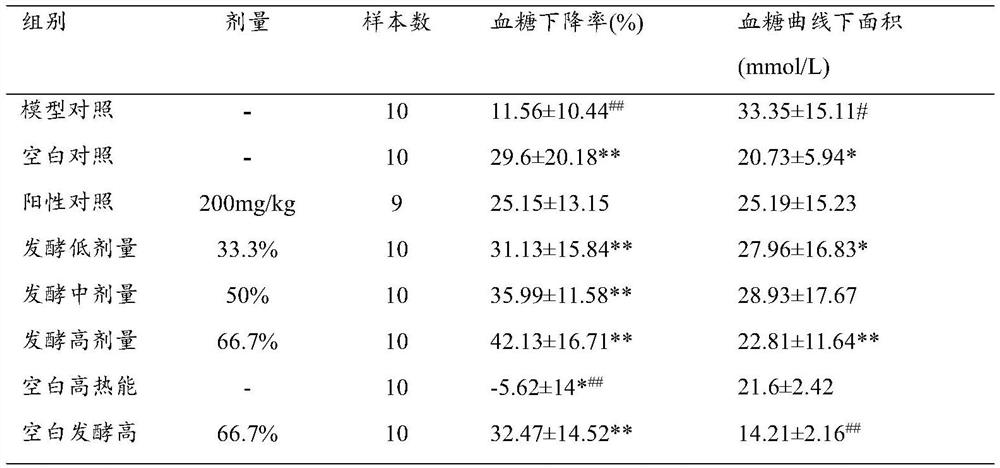

Wheat bran fiber powder with high pentosan content as well as preparation method and application of wheat bran fiber powder

PendingCN114868868ALower blood sugarDoes not affect regulationOrganic active ingredientsMetabolism disorderFiberWheat bran fiber

According to the preparation method and application of the bran fiber powder raw material with the high pentosan content, the method is rich in raw material source, mild in condition and simple in process, has important significance on wheat bran resource comprehensive utilization, and has wide market application prospects.

Owner:BINZHOU ZHONGYU FOOD +1

Microscopically observable cone-plate shear field generator

InactiveCN1866006BEasy to observeReal-time observationBiological testingMicroscopic observationEngineering

The invention discloses a cone-plate shear field generating device capable of microscopic observation, which includes: a base; a longitudinal driving device arranged on the base; a U-shaped bracket, the bottom of which is connected and arranged on the base On the longitudinal driving device; a liquid pan bracket, which is arranged on one side of the U-shaped bracket, and a liquid pan is arranged on the liquid pan bracket; a vertical driving device, which is arranged on the other side of the U-shaped bracket One side; a cone-plate support, the rear end of which is connected to the vertical drive device, and the lower part of the front end of the cone-plate support is provided with a cone-plate, the cone-plate is facing the liquid container, and is connected to the liquid container Coaxial; a motor, which is arranged on the cone-plate support, and the motor is connected with the cone-plate through a reduction transmission device. The structure of the invention does not affect the adjustment of the optical path of the microscope, so it can be used in conjunction with different types of microscopes, which is convenient for users.

Owner:BEIHANG UNIV

Multifunctional Motor Bearing Sealing Structure

ActiveCN108711997BReduce oilMeet the sealing performanceSupports/enclosures/casingsInlet channelEngineering

The present invention relates to fields relating to electric motor bearing sealing structures, and in particular to a multi-functional electric motor bearing sealing structure, aiming at solving the technical problems of single function of the current bearing sealing structure, lubricating grease in a bearing chamber tending to enter an electric motor, and oil mist in a gear box tending to enter the bearing chamber. The following technical solution is mainly used: an end cover is provided with a two-step stepped hole gradually expanding from inside to outside; the end cover is further provided with an air inlet channel with two ends respectively in communication with the outside atmosphere and a second through hole; an outer bearing cover is arranged adjacent to an outer side of a bearing cover; an inner ring of the outer bearing cover is provided with several annular grooves, and each annular groove is in communication with an oil return channel leading to a gear box; an outer ring of an outer sealing ring is provided with annular steps corresponding to the annular grooves; an inner end face of the outer bearing cover is further provided with an oil return cavity; and the end cover is further internally provided with a waste oil storage chamber in communication with the oil return cavity, and an exhaust channel with two ends respectively in communication with the second through hole and the oil return cavity. The present invention is mainly used for sealing a bearing of an electric motor.

Owner:CRRC YONGJI ELECTRIC CO LTD

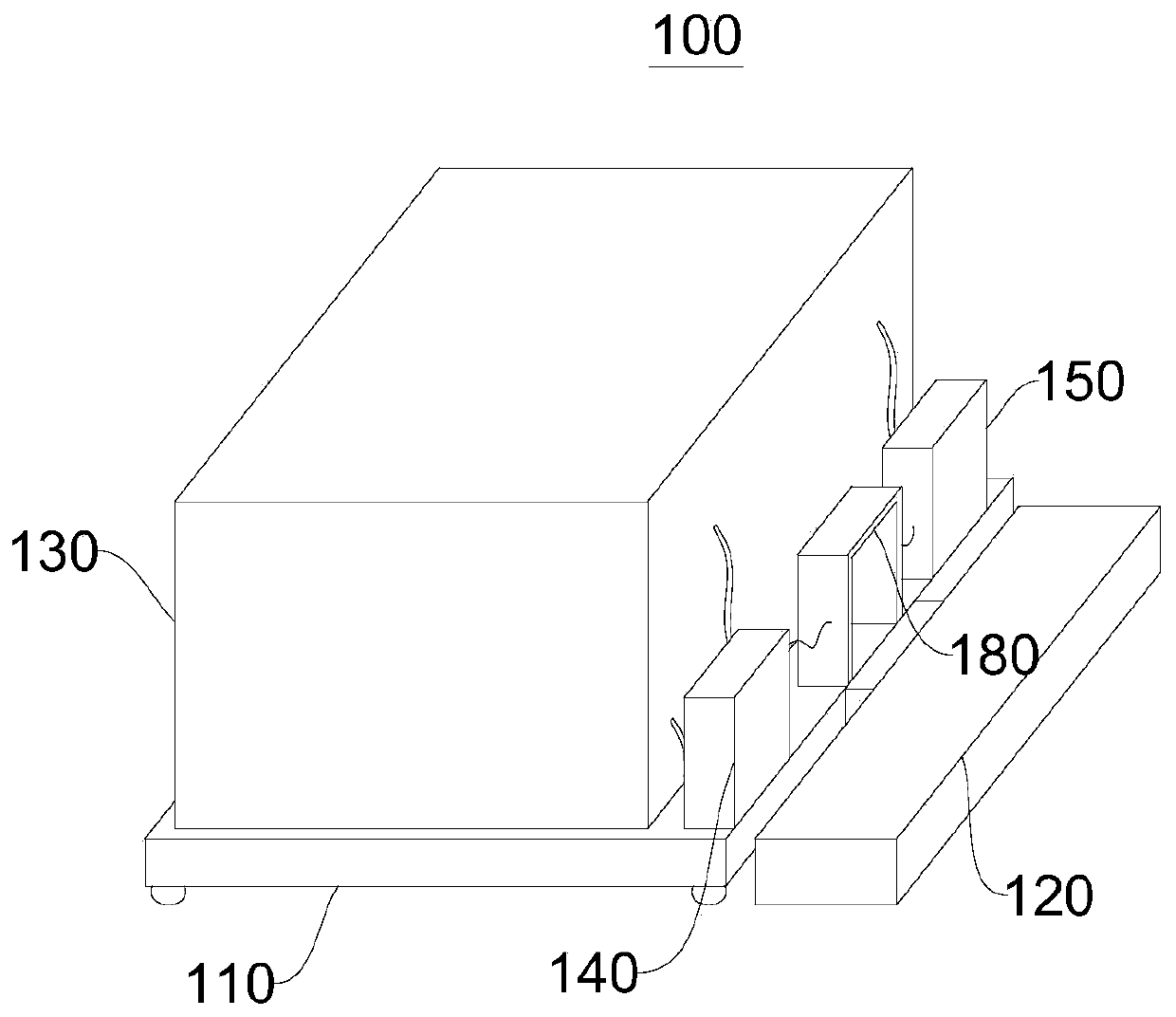

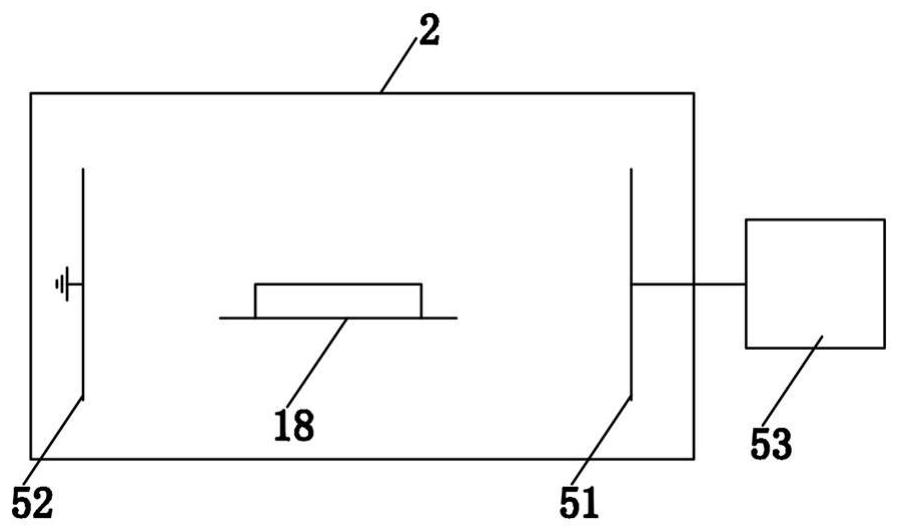

Control method and device for air conditioner cluster, air conditioner cluster and smart home system

ActiveCN111174377BDoes not affect regulationAccurate Actual Air IndexMechanical apparatusLighting and heating apparatusControl engineeringProcess engineering

The invention discloses a control method for an air conditioner cluster, which belongs to the technical field of air conditioning. The method includes: controlling the movement of two or more movable air conditioners according to two or more set cruising routes; The actual air index; determine the corrected second actual air index of the first position according to two or more air indices; control two or more movable air conditioners to adjust the actual air in the first position according to the second actual air index index. Accurate actual air indicators can be obtained by adopting the technical scheme. The embodiment of the invention also discloses a control device for an air conditioner cluster, an air conditioner cluster and a smart home system.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

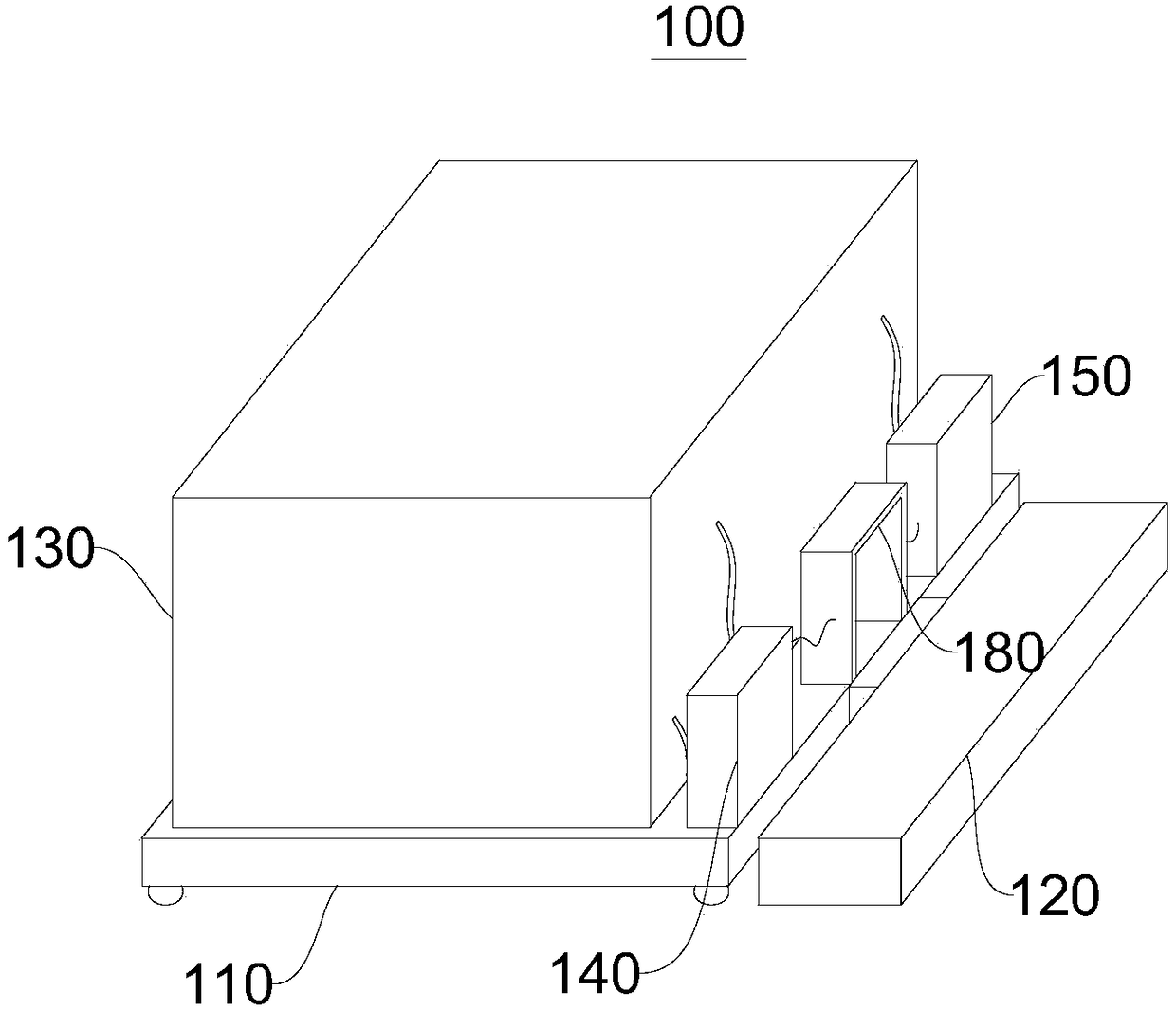

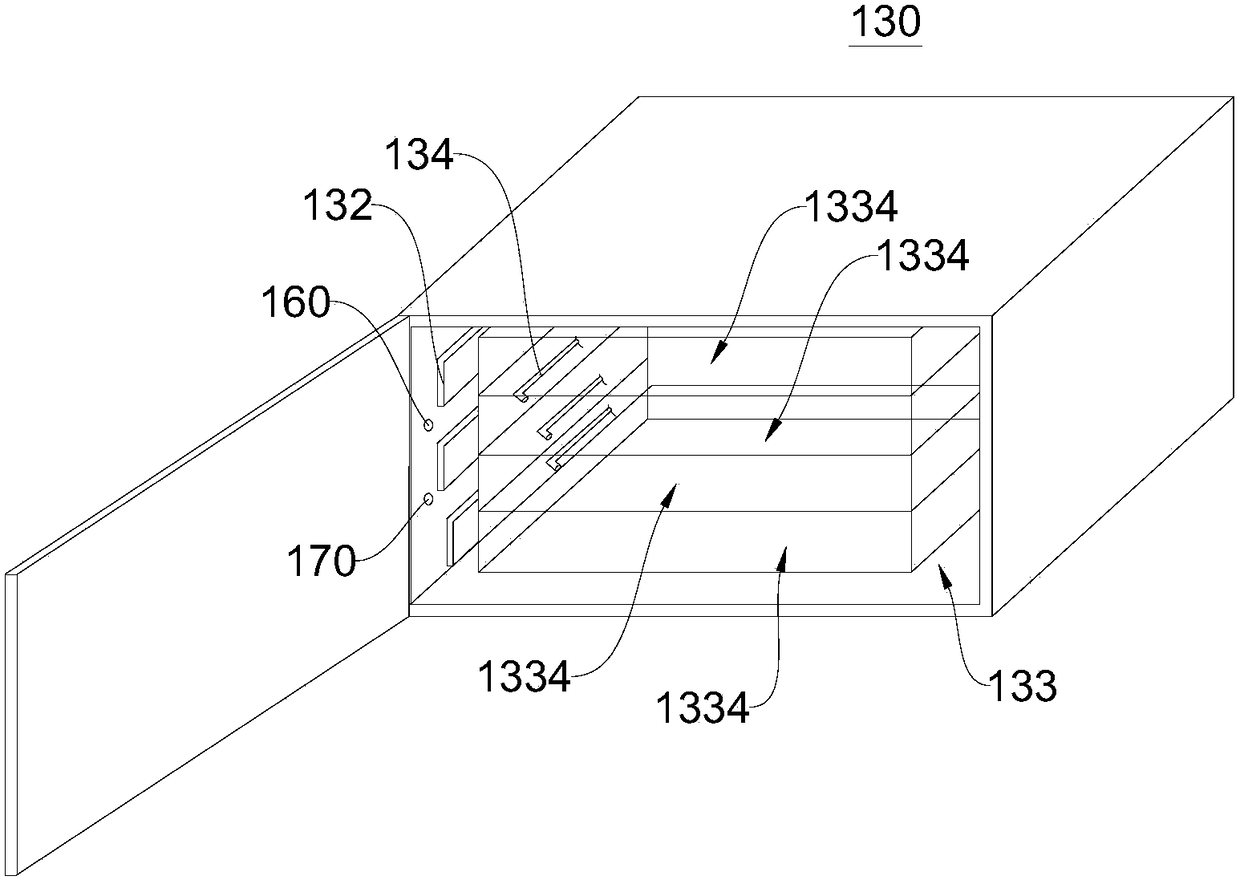

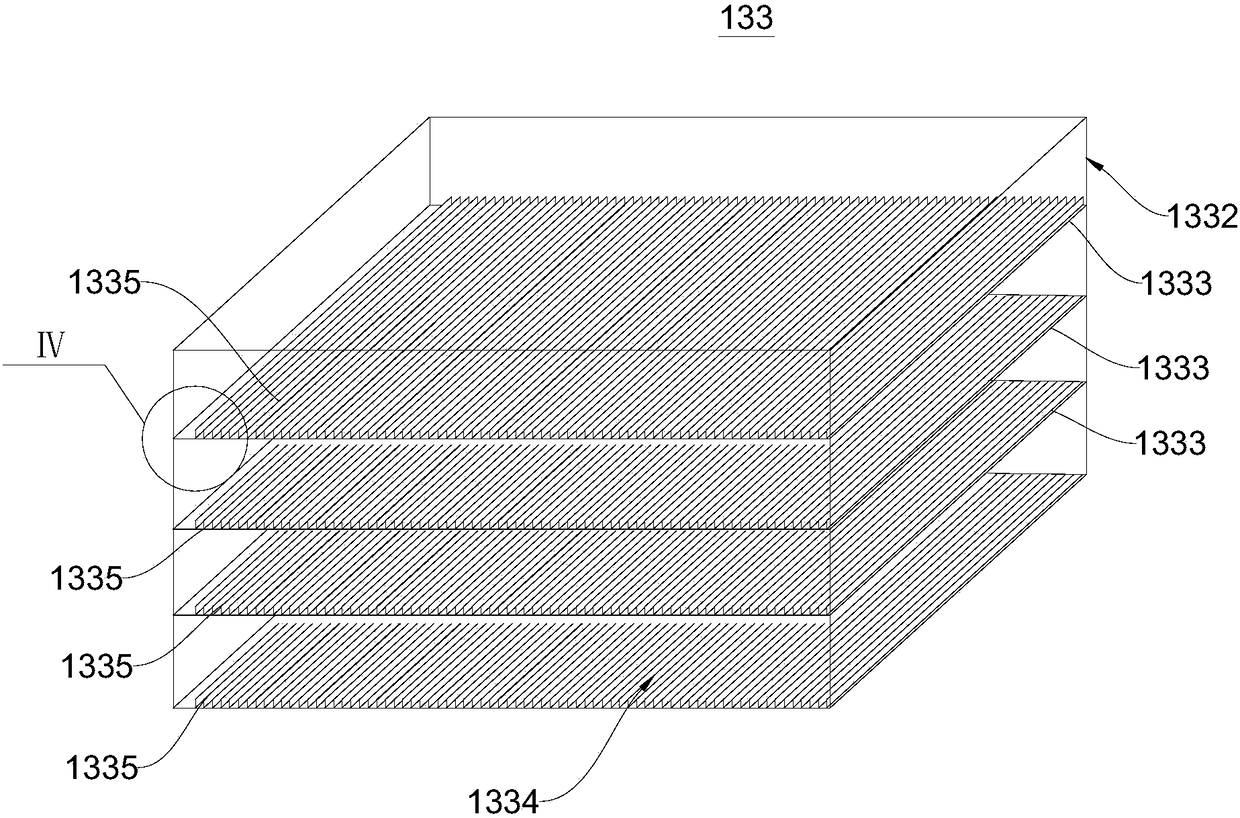

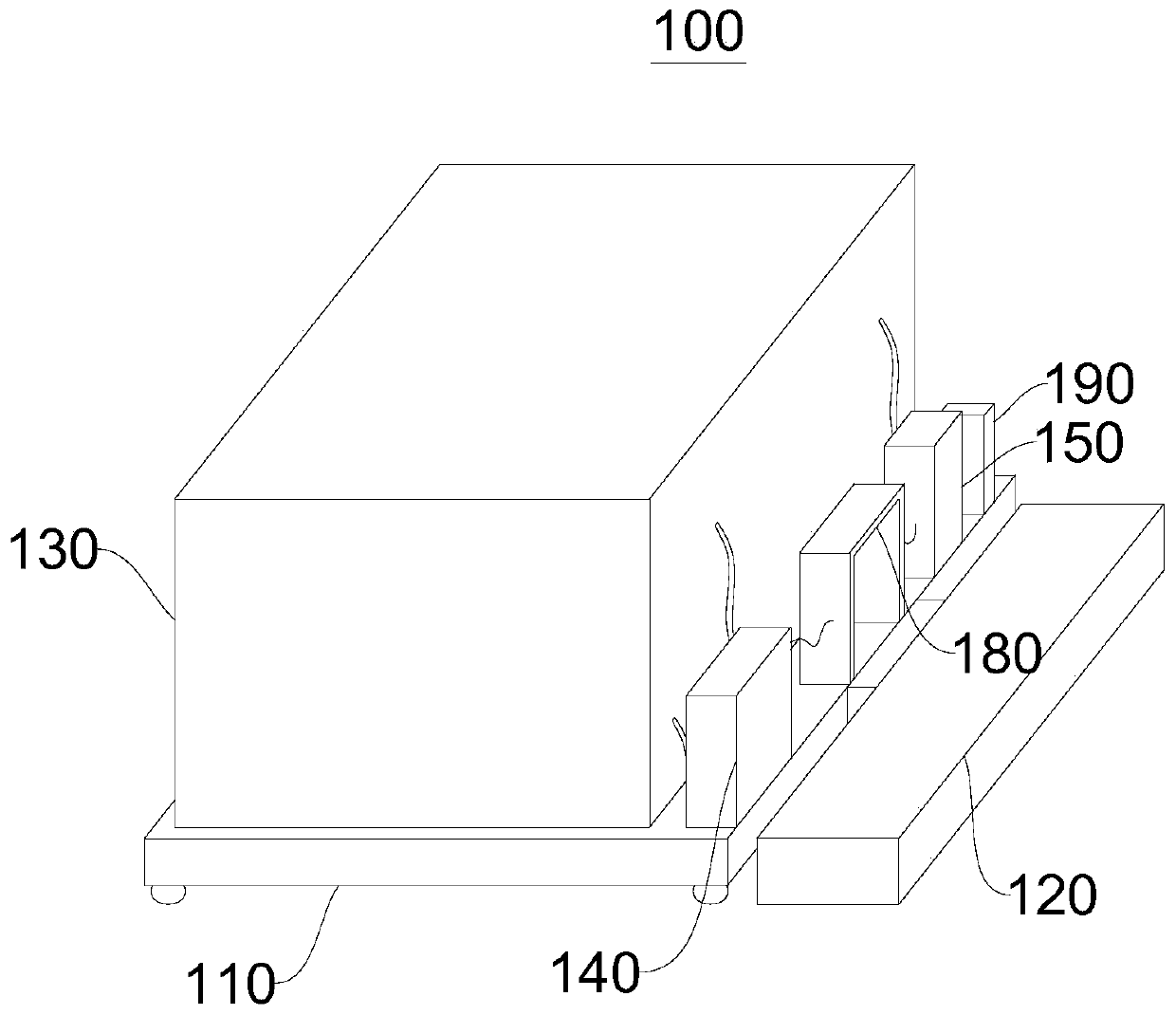

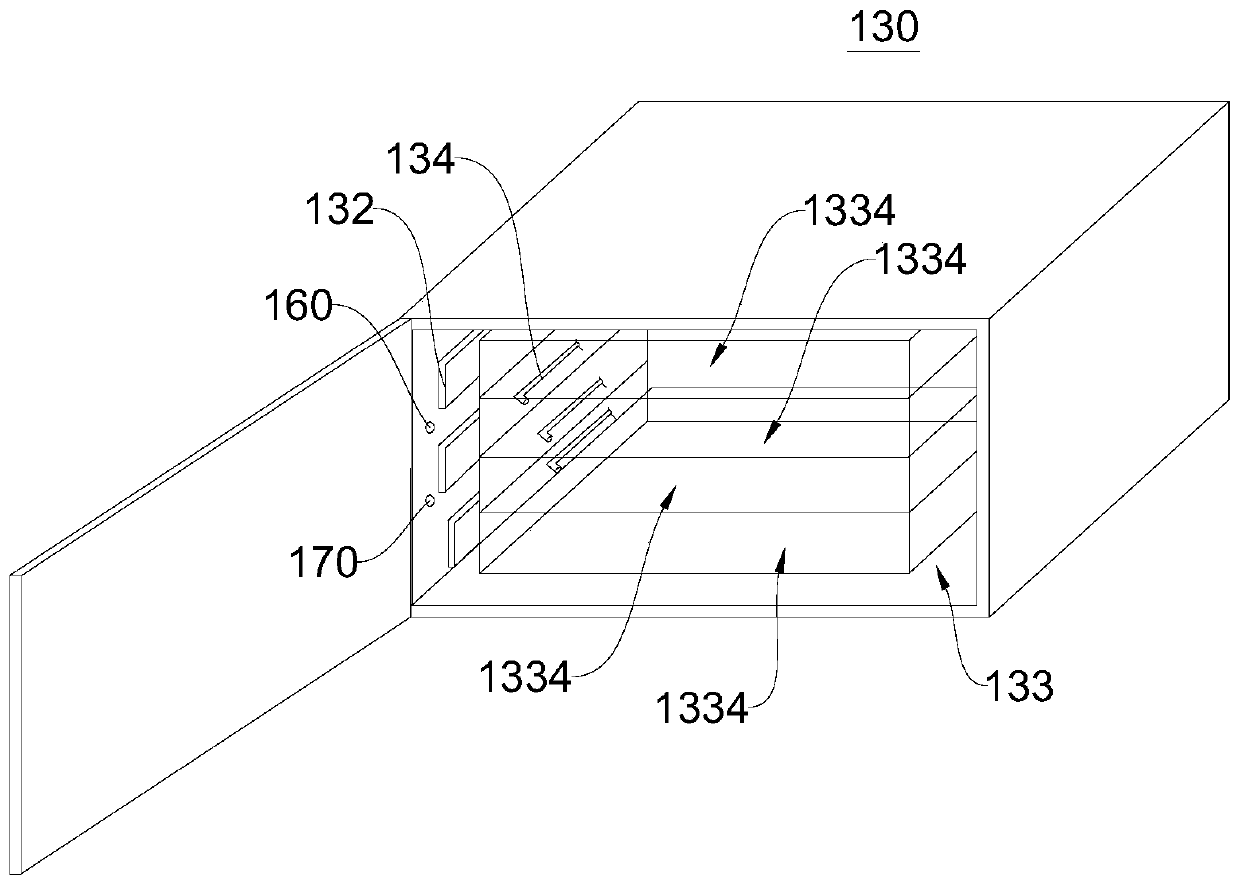

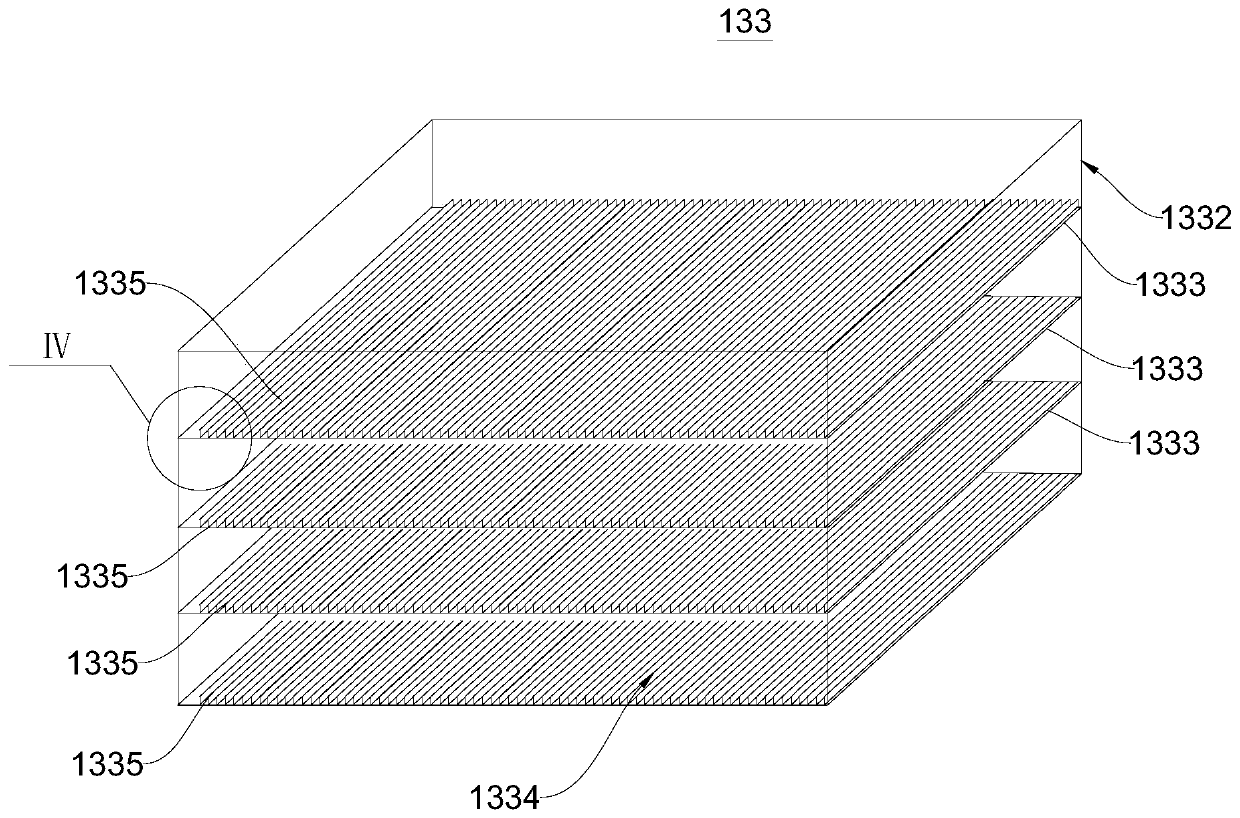

A partition wall board steam curing method and partition wall board steam curing device

InactiveCN108214848BDoes not affect regulationAvoid sureCeramic shaping apparatusTemperature controlProcess engineering

The invention discloses a partition wall board steam curing method and a partition wall board steam curing device, and relates to the technical field of concrete curing. According to the partition wall board steam curing method, a partition wall board to be cured is placed on a curing layer in a curing room after being bundled; the temperature is controlled through an oil conveying pipeline for heating in a curing process; the humidity is controlled by introducing steam through a steam pipeline; the temperature and the humidity can be controlled accurately; and the flexibility is high. According to the partition wall board steam curing device, the curing room is arranged on a base; the base is moved through a traction machine; the flexibility of a curing place is high; the labour intensityof an operator is reduced in a transportation process; and the oil for heating is provided through an oil heat transfer boiler, so that the temperature in the curing room is controlled accurately.

Owner:四川省劲腾环保建材有限公司

A dual-drive grinding device for mechanical manufacturing

InactiveCN108568751BEffective regulationMeet the needs of different surface grindingGrinding drivesGrinding machinesDrive shaftGrinding wheel

The invention discloses a dual-drive polishing device for machinery manufacturing. The dual-drive polishing device comprises a moving mechanism, a drive box, a motor I, a driven gear I, a driving gearI, a driving belt pulley I, a polishing motor I, a drive belt I, a driven belt pulley, an end cover, a polishing motor II, a drive belt II, a driving belt pulley II, a driving gear II, a motor II, adriven gear II, a bearing, a fixing cover I, an outer sleeve, an inner sleeve and a drive shaft. The dual-drive polishing device is reasonable and simple in structure, low in production cost and convenient to mount; the motor II and the motor I are arranged, the polishing angle of a grinding wheel can be effectively adjusted, the requirement of polishing of different surfaces of the same part is met, and the polishing efficiency and accuracy are improved. The motor I and the motor II are both stepping motors, so that accurate control through the prior art is facilitated. A transition end surface gear is arranged and can effectively transfer power of polishing motors to the grinding wheel, and the adjustment of different angles of the grinding wheel is not affected.

Owner:JINING UNIV

A steam curing method for a partition board and a steam curing method for concrete products

InactiveCN108407063BDoes not affect regulationPrecise temperature controlCeramic shaping apparatusTemperature controlEngineering

The invention discloses a partition wall plate steam curing method and a steam curing method for concrete products, and relates to the technical field of concrete curing. According to the partition wall plate steam curing method, to-be-cured partition wall plates are bundled and then placed in a curing chamber, temperature control is conducted through an oil delivery pipeline for heating in the curing process, steam is introduced through a steam pipeline for humidity control, the temperature and humidity can be precisely controlled, meanwhile, adjusting and controlling of the humidity are notaffected by controlling over the humidity, and thus operation flexibility is high; and temperature control in the curing process is divided into three times of temperature increasing, the great curingeffect is obtained, finally, it is ensured that the water content on the surface of a component after natural temperature decreasing reaches the specified requirement, repeated detecting is avoided,and the time and labor are saved. The steam curing method for the concrete products comprises the partition wall plate steam curing method, the flexibility of temperature and humidity control can be significantly improved, and the temperature control precision is high.

Owner:四川省劲腾环保建材有限公司

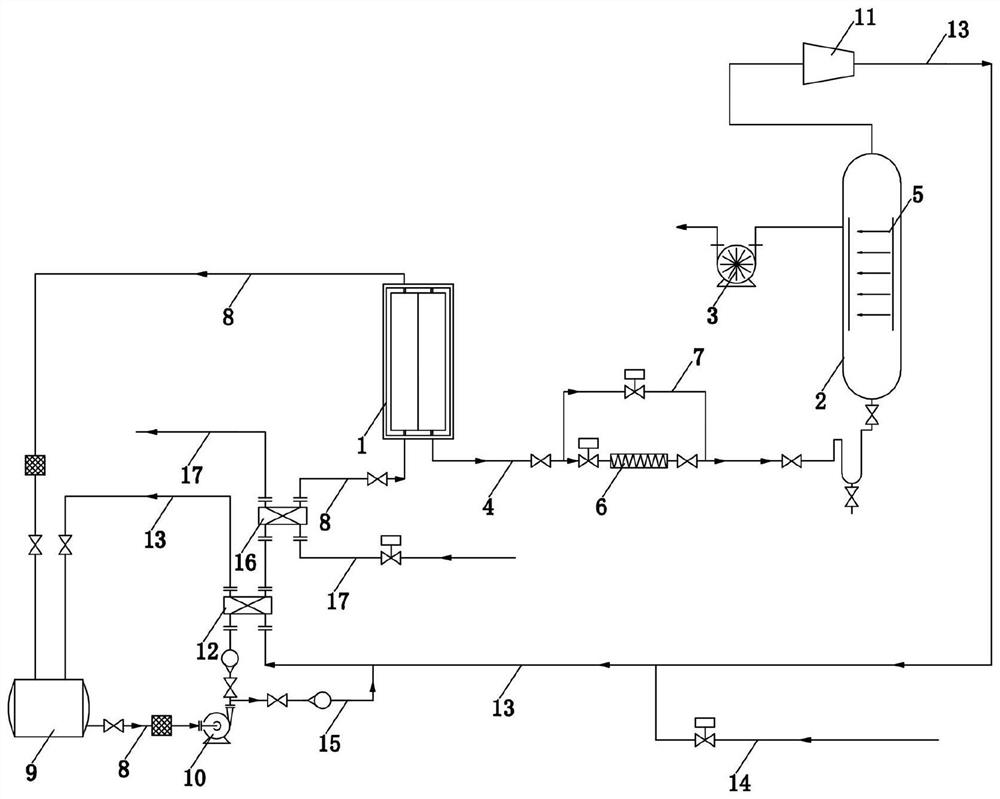

High-voltage electric field film drying system

PendingCN113375430AGuaranteed service lifeAvoid wasting time and effortDrying solid materials with heatDrying solid materials without heatThermodynamicsActive component

The invention relates to the technical field of material drying, and discloses a high-voltage electric field film drying system. The high-voltage electric field film drying system comprises a film assembly, a dryer and a vacuum pump. The hot-side film surface of the film assembly is used for introducing hot water with a preset temperature, and the cold-side film surface of the film assembly sequentially communicates with the dryer and the vacuum pump through a first pipeline. A high-voltage electric field is arranged in the dryer. According to the high-voltage electric field film drying system, the high-voltage electric field drying technology and the film distillation technology are ingeniously coupled and are combined to dry the materials, so that the cost is low, the drying efficiency and the drying quality of the materials are greatly improved, and the high-voltage electric field film drying system is particularly suitable for drying high-added-value materials containing thermal instability active components.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Vane-guided high-pressure series spool structure

The invention relates to a vane guiding high-pressure string-type valve core structure. The vane guiding high-pressure string-type valve core structure comprises a valve body, a valve seat is mounted in the valve body, a string-type valve core is disposed in the valve seat, and a guiding pressure sleeve is fixed on the upper portion of the valve seat. The vane guiding high-pressure string-type valve core structure is characterized in that a plurality of circulating holes are formed from bottom to top along an inner cavity of the valve seat, inner diameter of the circulating holes is larger than that of the inner cavity of the valve seat, the string-type valve core penetrates the circulating holes, a plurality of vanes are distributed on the string-type valve core, outer circles of the vanes are tightly matched with the inner cavity of the valve seat, transition between lower ends of the vanes and the outer surface of the string-type valve core is achieved by means of first section circular arcs, transition between the lower ends of the vanes and upper ends of the vanes is achieved by means of second section circular arcs, the first section circular arcs and the second section circular arcs form adjusting curved surfaces, lengths of adjusting curved surfaces of all vanes are equal, and the top of the string-type valve core and the top of the inner cavity of the valve seat are sealed by means of a conical sealing surface. By means of the vane guiding high-pressure string-type valve core structure, phenomena of fluid flash evaporation and cavitation can be effectively reduced, washing of media to valve trim is decreased, and noise is reduced.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

Vehicle lateral-rear blind zone mirror

The invention provides a vehicle lateral-rear blind zone mirror, belongs to the technical field of vehicles, and particularly relates to a vehicle rearview mirror technology. In the lateral-rear blindzone of a vehicle, the blind zone problem can be solved through the vehicle lateral-rear blind zone mirror; the influence on an original vehicle exterior rearview mirror is avoided, the original vehicle exterior rearview mirror does not need to be refitted, and the vehicle lateral-rear blind zone mirror is prevented from being additionally mounted on the original vehicle exterior rearview mirror;the vehicle lateral-rear blind zone mirror is mounted at a corner near a vehicle interior window; and during the vehicle exterior rearview mirror observation process of a driver, the driver sees thevehicle lateral-rear blind zone mirror at first when moving the sight from the interior of the vehicle to the vehicle exterior rearview mirror, and then sees the vehicle exterior rearview mirror aftermoving the sight.

Owner:王飞

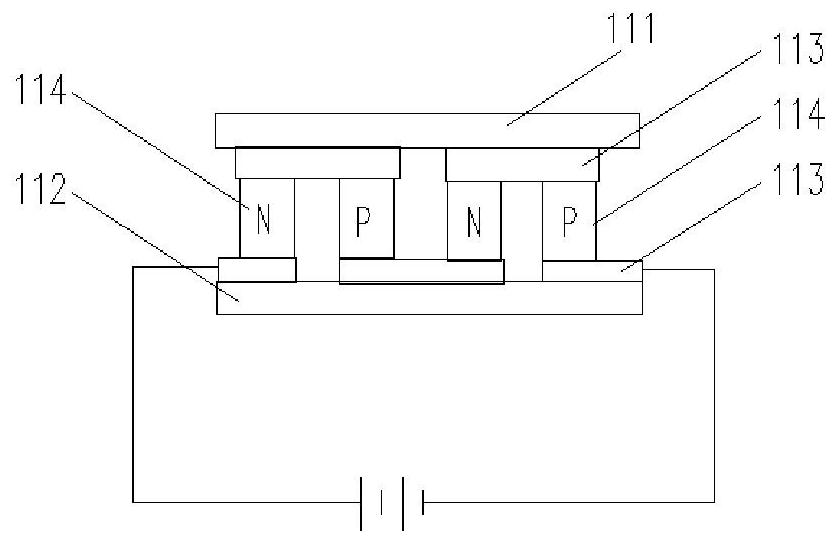

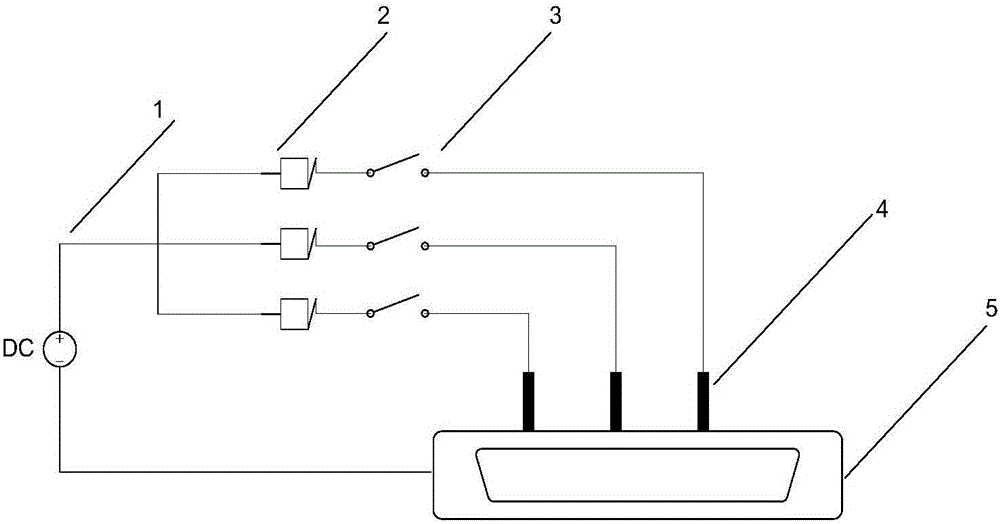

Electric circuit type device for probe consistency calibration of spark discharge devices and calibration method thereof

InactiveCN105973138AVerify Probe ConsistencySimple methodUsing electrical meansSpark dischargeElectron

The invention discloses an electric circuit type device for probe consistency calibration of spark discharge devices, wherein the electric circuit type device belongs to the field of power electronic technology. The electric circuit type device comprises a power supply, a reminding device, a switch, the probe of a spark discharge device, and a calibration plane, wherein the reminding device, the switch and the probe of the spark discharge device are successively connected for forming a serial circuit. After n series circuits are parallelly connected (n is an integer which is larger than or equal with one), an acquired parallel circuit is connected with the anode of the power supply. The cathode of the power supply is connected with the calibration plane. The probe of the spark discharge device vertically contacts with the calibration plane. Through conduction of the electric circuit, probe consistency of the spark discharge device is verified in an indirect manner. Simple operation of the method and wide application range are realized. Through conduction of a reminding circuit of the reminding device, Adjustment of the spark discharge device is not affected, thereby realizing higher intuitiveness.

Owner:CHANGCHUN JLU KENUO TECH CO LTD

Device for adjusting angle of LED automobile lamp

The invention discloses a device for adjusting the angle of an LED automobile lamp. The device comprises an automobile lamp mounting rack and also comprises a fixed plate. The fixed plate is mounted on an operating panel of a driver cab, the automobile lamp mounting rack is mounted on the left and right sides of the automobile head, a rotating ball is arranged at the center of the fixed plate, a vertical adjusting ring and a transverse adjusting ring are vertically arranged on the rotating ball, the vertical adjusting ring and the transverse adjusting ring rotate on a track in a fixed direction through a transmission ball, the vertical adjusting ring and the transverse adjusting ring rotate a vertical rack and a transverse rod through mechanical transfer of a tooth, the vertical rack is mounted on a mounting back seat, and the transverse rack is mounted on a positioning rack. By movably adjusting the LED automobile lamp, the LED automobile lamp can be adjusted up and down for the convenience of illumination and can be adjusted left and right, so that the sight of a driver is wider and the driver sees more clearly in a road where people or animals are likely to traverse on two sidesparticularly.

Owner:YANYANG LAMP SET TIANCHANG CITY

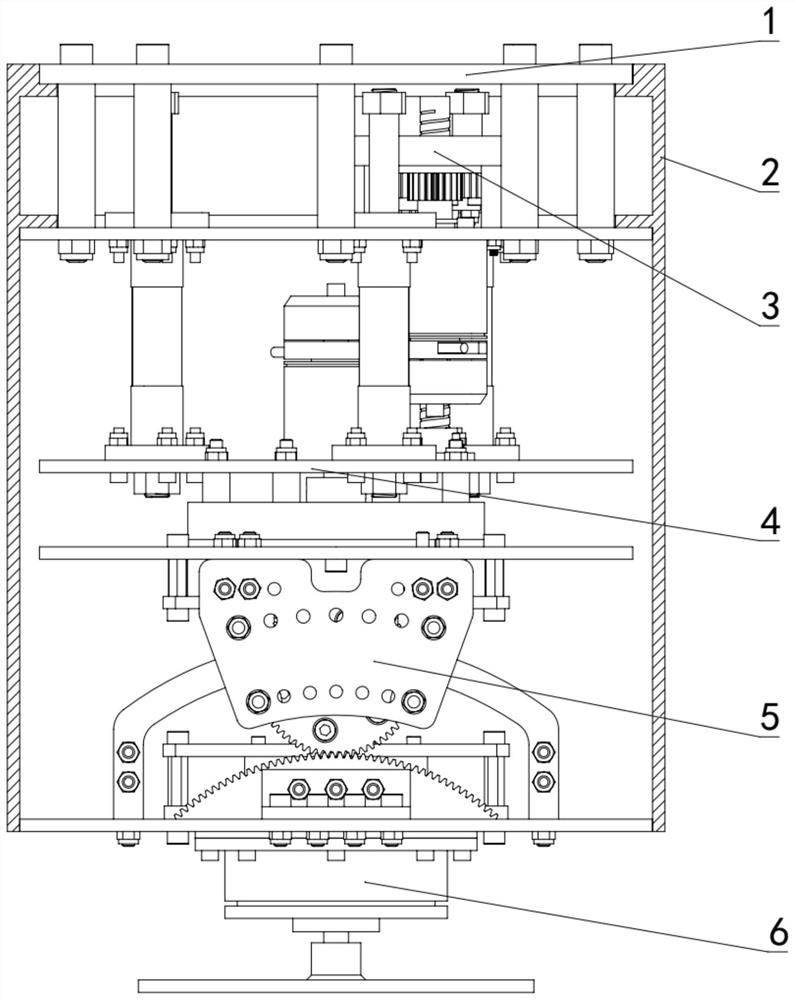

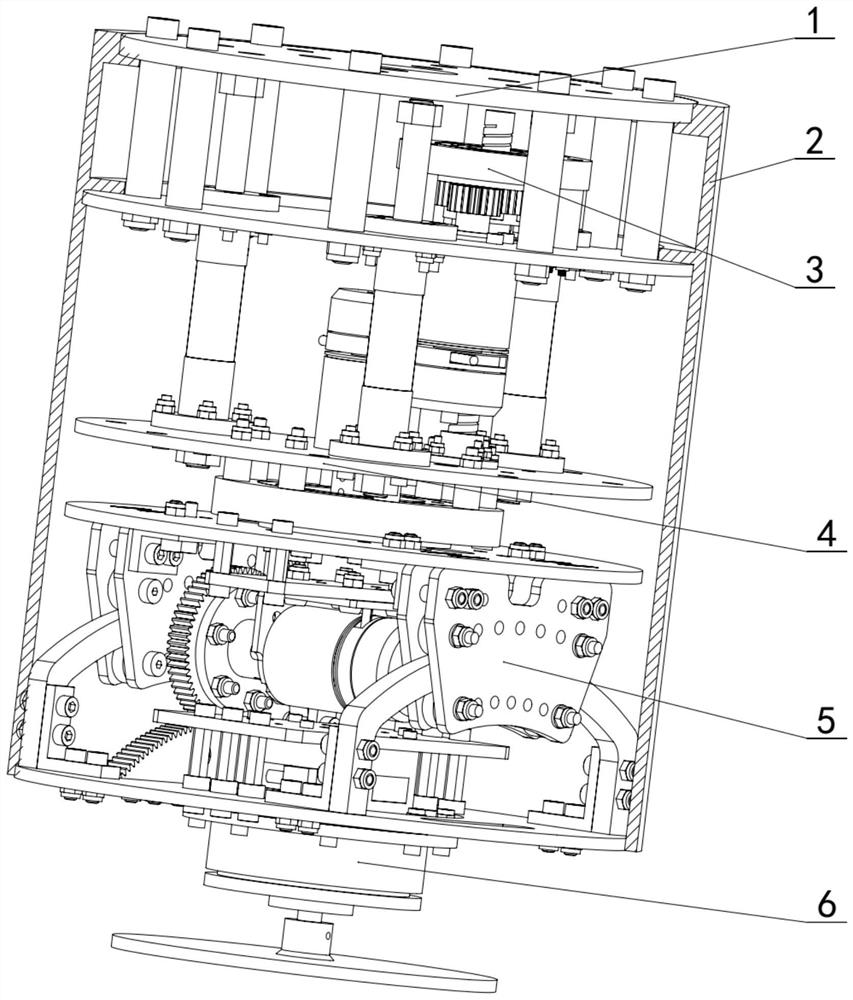

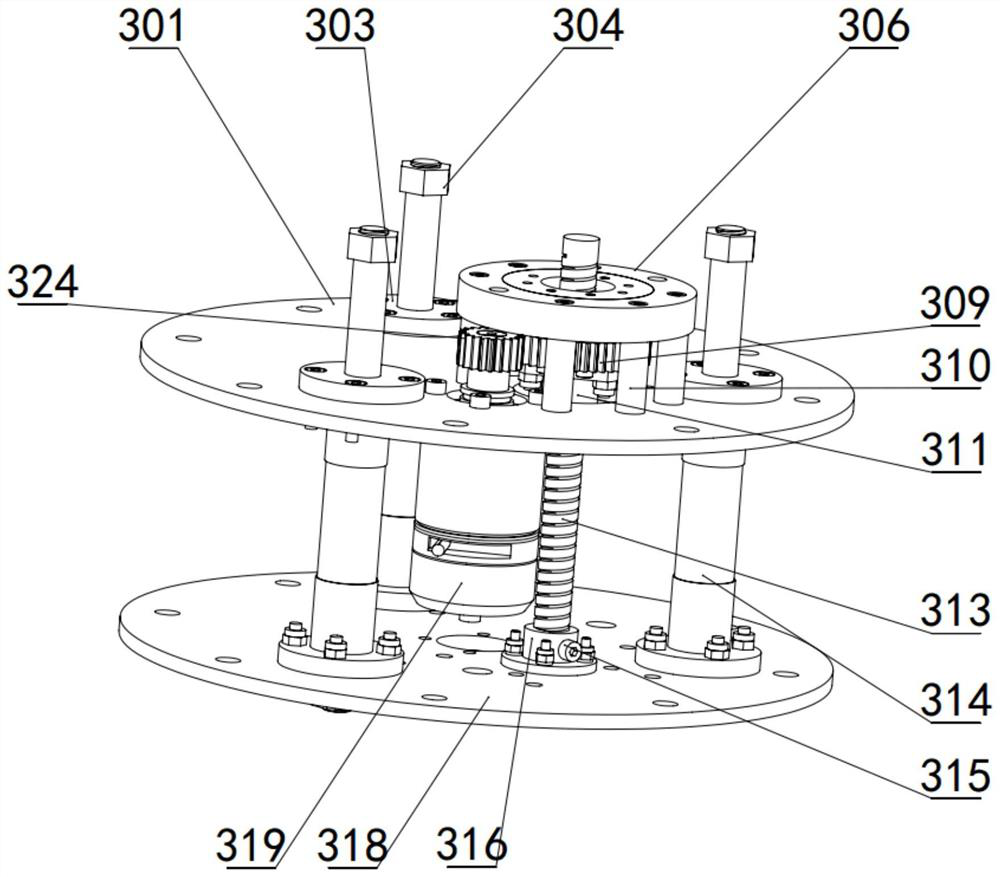

Three-degree-of-freedom adaptive flexible grinding and polishing device and robot for large complex curved surfaces

ActiveCN110103114BDoes not affect regulationGuaranteed grinding and polishing accuracyGrinding drivesGrinding feed controlRotational axisLinear motion

The invention discloses a three-degree-of-freedom self-adaptive flexible grinding and polishing device for a large complex curved surface and a robot thereof, and belongs to the field of intelligent processing equipment for curved surface workpieces. The device comprises a controller, a linear motion mechanism, a rotary adjusting mechanism and a pitching adjusting mechanism, wherein the linear motion mechanism, the rotary adjusting mechanism and the pitching adjusting mechanism are sequentially arranged from top to bottom; the linear motion mechanism is used for driving other mechanisms to doup-and-down linear motion; the rotary adjusting mechanism is used for driving other mechanisms to do rotary motion; a rotary shaft of the rotary adjusting mechanism is parallel to the linear motion direction and coincides with the center of the lower surface of a grinding disc; the pitching adjusting mechanism is used for driving a grinding and polishing mechanism to rotate; a rotating shaft of the pitching adjusting mechanism is perpendicular to the linear motion direction and coincides with the center of the lower surface of the grinding disc; and the controller is respectively connected with the four mechanisms and is used for controlling the other mechanisms to move according to the measurement result of a six-dimensional force sensor so as to adjust the polishing force and the postureof the grinding and polishing mechanism in real time. The polishing robot is available by mounting equipment at the tail end of a robot. The equipment has the advantages of high grinding and polishing precision, long service life and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

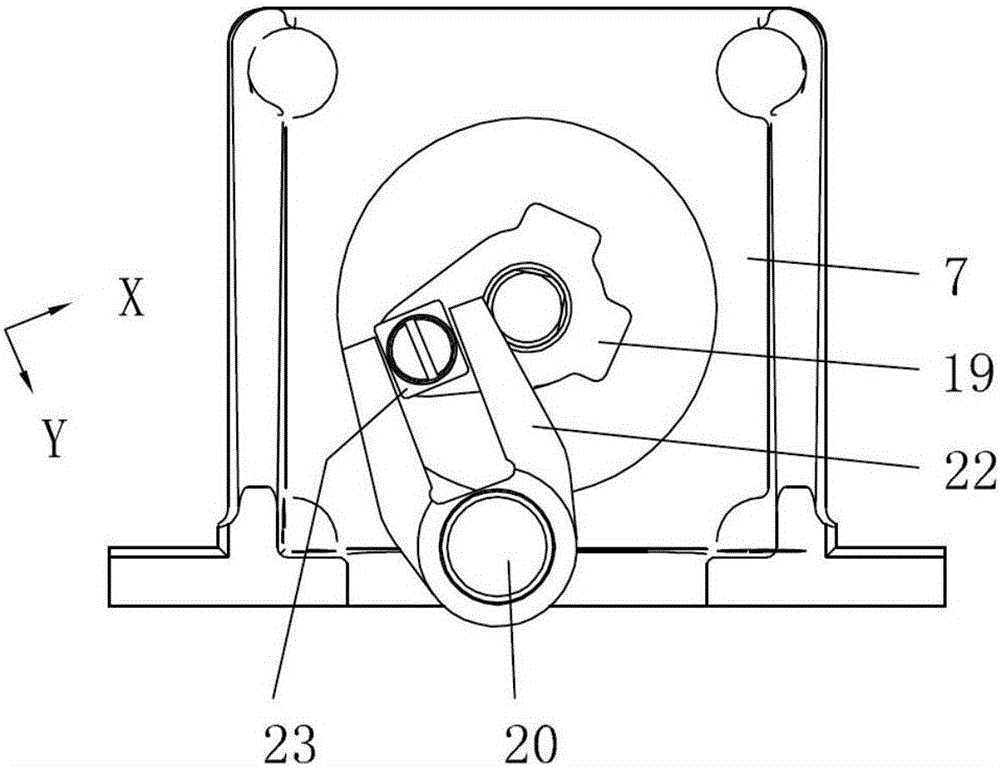

A Positioning Mechanism for Machining Adaptable to Various Orbits

ActiveCN112658739BEasy to adjustHigh precisionPositioning apparatusMetal working apparatusClassical mechanicsCard holder

The invention discloses a positioning mechanism for machining that can adapt to various tracks, including an adjustment mechanism, a guide mechanism, a connection mechanism and a limit mechanism. The lower end surface of the adjustment mechanism is threaded and slidably connected with a guide mechanism for positioning. If the present invention needs to adapt to different shapes of support plates and limit guide rails, such as square or arc shapes, when the shape of the support plate is square or other non-circular shapes, due to the different shapes, during the rotation process, the position limit The card seat can slide inside the positioning chute, so as to provide enough limit space for the limit mechanism to slide outside the limit guide rail. At the same time, the connecting sleeve shaft can provide enough space for the expansion and contraction of the limit card seat by cooperating with the transmission rod The limit space, and because the connecting sleeve shaft and the transmission rod are slidingly clamped, the limit tooth does not affect the subsequent adjustment of the positioning angle of the mounting seat, which effectively improves the adaptability of the device.

Owner:青岛祥银传动设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com