Wheat bran fiber powder with high pentosan content as well as preparation method and application of wheat bran fiber powder

A technology for wheat bran and high pentosan, which is applied in the field of applied biology, can solve the problems of poor eating taste, cannot be widely eaten, and the dietary fiber of wheat bran cannot meet the development and application in the field of food processing, so as to reduce fasting. blood sugar effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

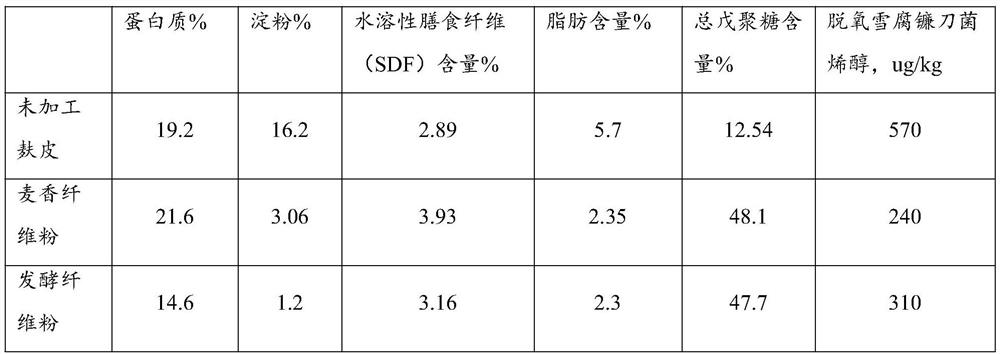

[0036] Embodiment 1, wheat dietary fiber pure physical processing technology

[0037] The present embodiment provides a processing technique of wheat dietary fiber, specifically, the technique comprises the following steps:

[0038] (1) Bran pretreatment: moderately pulverize the wheat bran and pass through a 60-mesh sieve;

[0039] (2) High temperature degradation: mix wheat bran and water into the mixing tank, the ratio of bran to water is 1:8, stir and heat with steam for 30-45min;

[0040] (3) Cleaning: After the material is dehydrated by the horizontal screw centrifuge, it enters the mixing tank again. The ratio of wet material to water is 1:8, and stirring is performed while adding water;

[0041] (4) Dehydration: After the material is dehydrated by the horizontal screw centrifuge, the primary separation slurry is obtained, and then the primary separation slurry is sent to the vacuum dehydrator for solid-liquid separation again;

[0042] (5) Roasting: after preheating ...

Embodiment 2

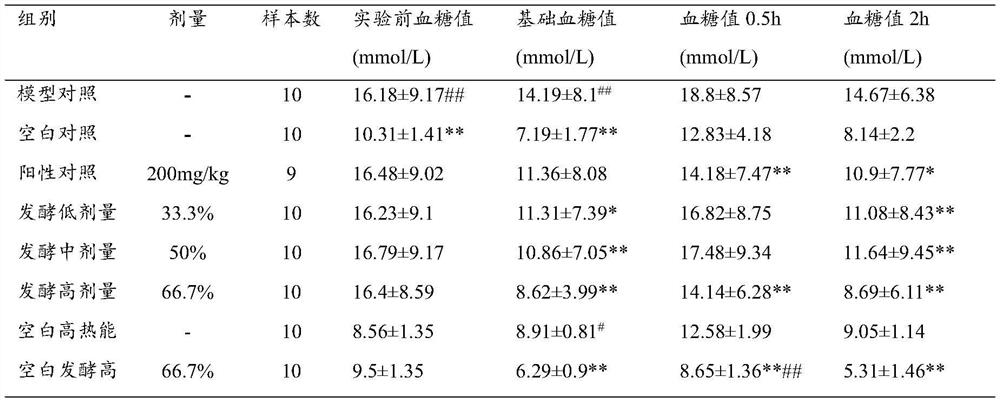

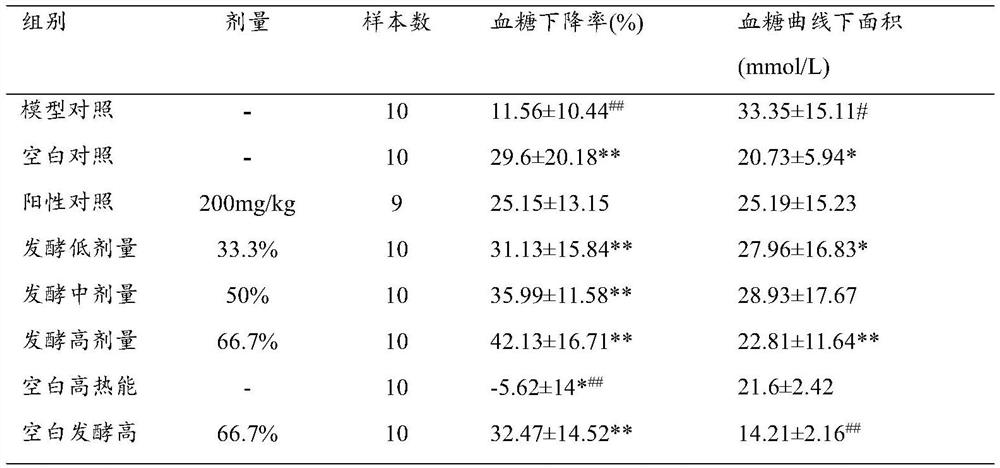

[0052] Example 2. Hypoglycemic and hypolipidemic effects of wheat dietary fiber

[0053] In this embodiment, the hypoglycemic and hypolipidemic effects of the wheat dietary fiber (taking fermented fiber powder as an example) prepared by using wheat bran in Example 1 are used to study.

[0054] 2.1. Preparation of mouse feed for hypoglycemic test in mice: fermented fiber powder, maintenance material, calcium carbonate and sodium carboxymethyl cellulose are self-made.

[0055] High-dose special feed (fermented high-dose): 66 parts of fermented fiber powder, 33 parts of maintenance material, 1 part of calcium carbonate, 100 parts of 5% sodium carboxymethyl cellulose

[0056] Medium-dose special feed (fermented medium-dose): 49 parts of fermented fiber powder, 49 parts of maintenance material, 1 part of calcium carbonate, 100 parts of 5% sodium carboxymethyl cellulose

[0057] Low-dose special feed (fermented low-dose): 33 parts of fermented fiber powder, 66 parts of maintenance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com