Self-operated multi-stage throttling lubricating oil pressure regulating valve

A technology of throttling lubricating oil and pressure adjustment, applied in valve details, safety valve, balance valve, etc., can solve the problems of unadjustable throttling aperture, unfavorable vibration and noise reduction of the unit, large pressure difference between front and rear, and achieve light weight. , Simple structure, reducing the effect of violent fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

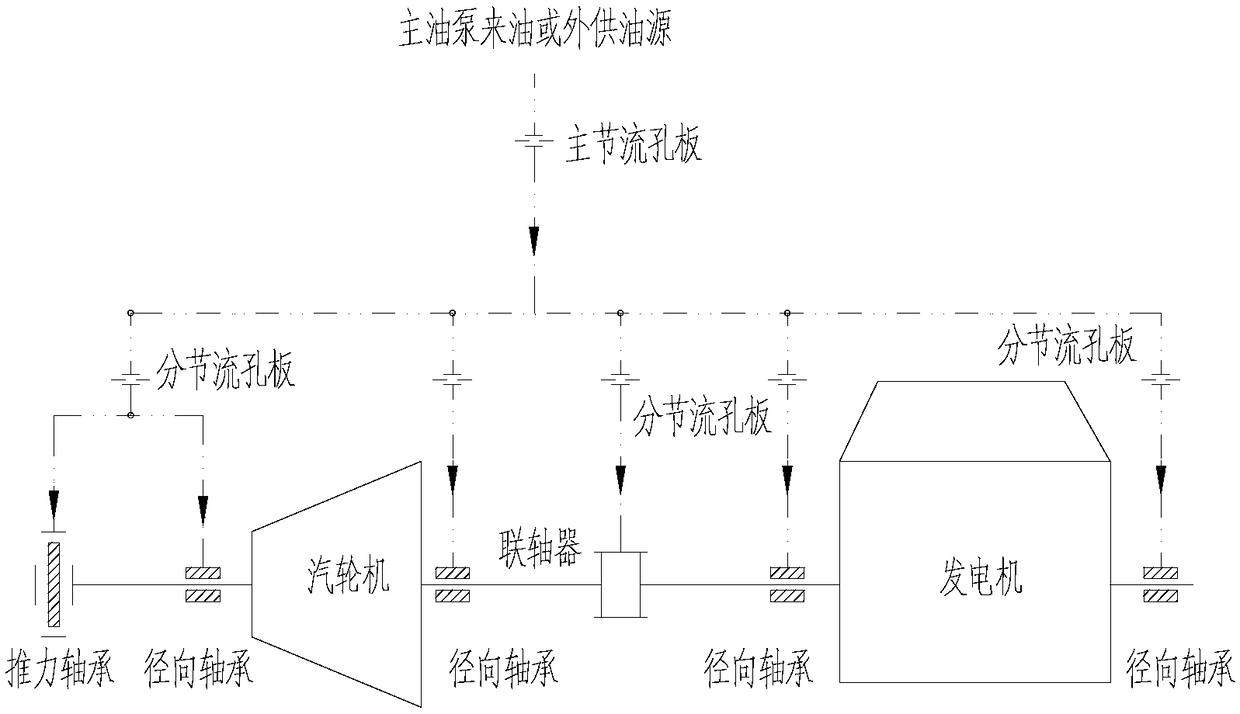

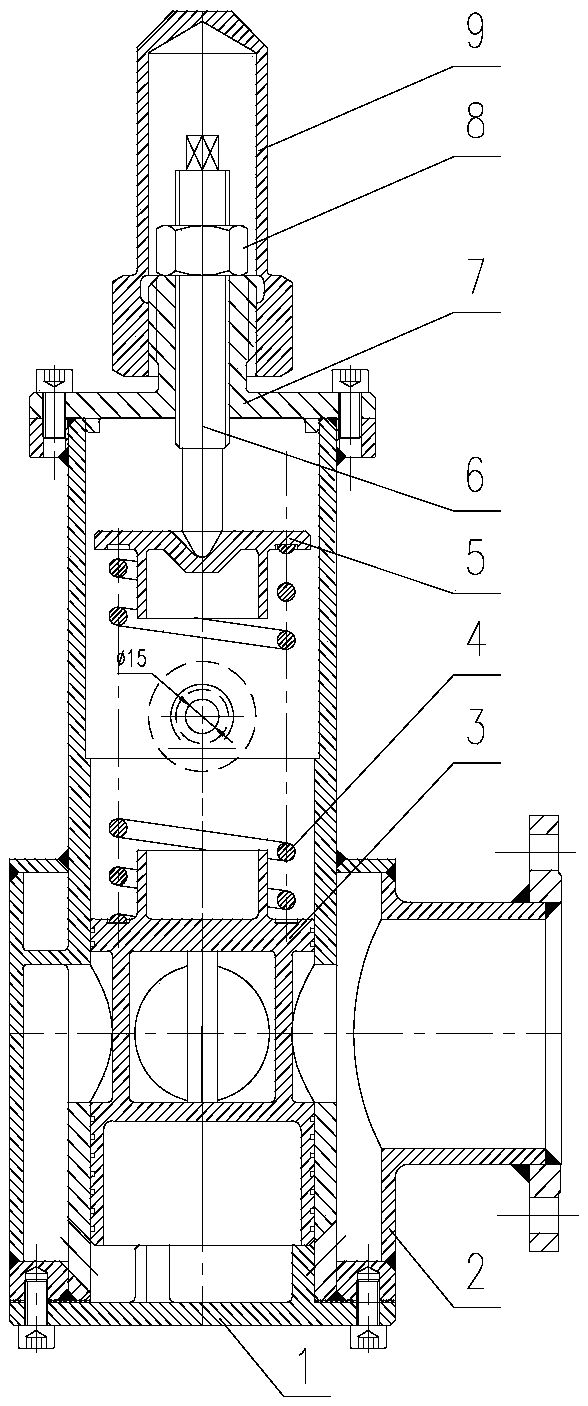

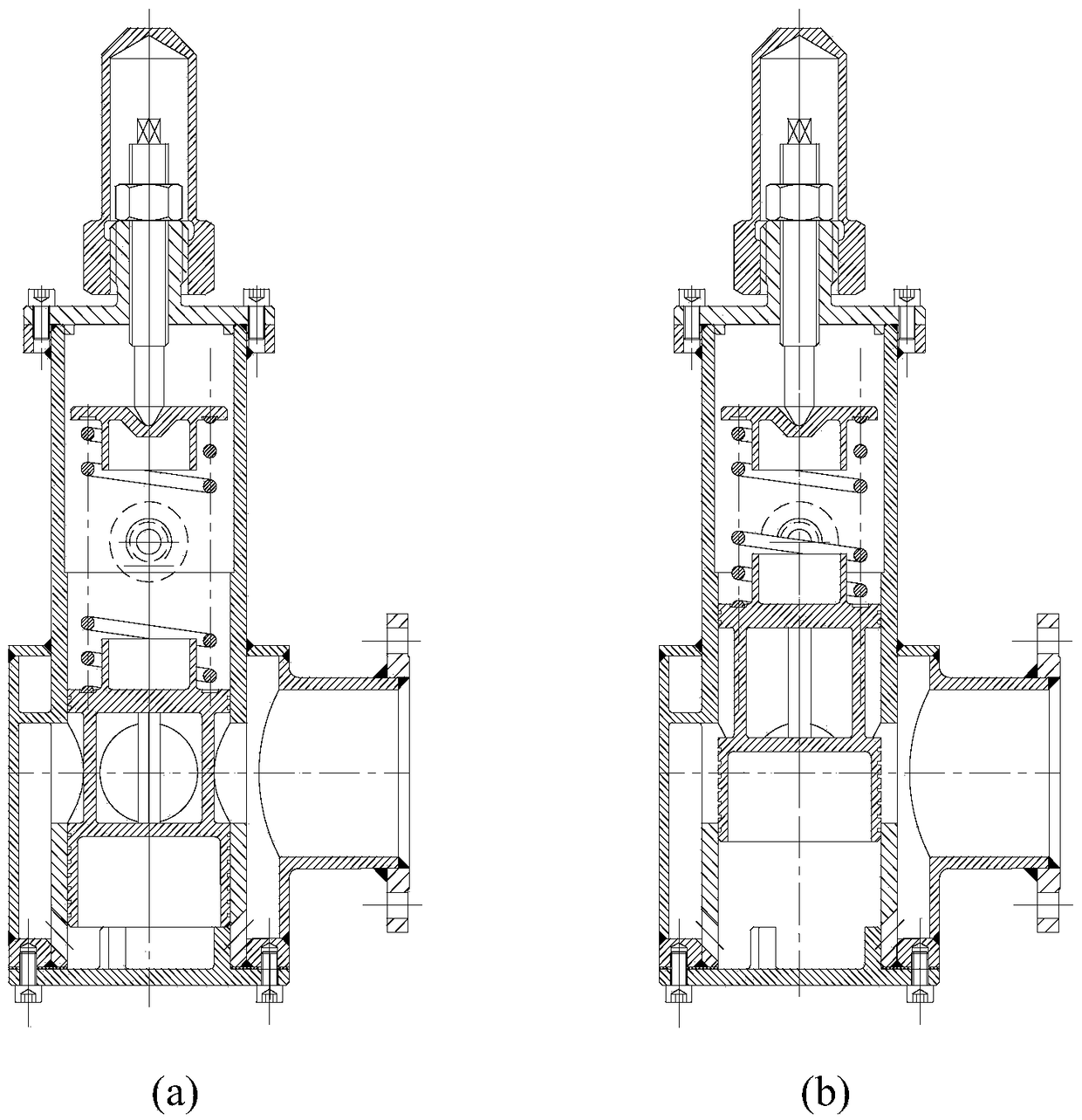

[0021] like figure 2 As shown, a self-operated multi-stage throttling lubricating oil pressure regulating valve consists of a bottom cover 1, a housing 2, a slide valve 3, a spring 4, a gland 5, a screw 6, an upper cover 7, a nut 8, and a cover 9 And related fasteners and seals. The housing 2 of the regulating valve is composed of an inner housing and an outer housing: the outer housing is provided with inlet and outlet flanges and leak port joints, and the bottom of the inner housing is provided with a slanted hole to connect the outlet and the cavity at the bottom of the inner housing. room. The spool valve 3 is set inside the housing 2, the bottom cover 1 is installed at the lower end of the housing 2, and its protruding flange is set inside the housing 2, and becomes a limit for the downward movement of the spool valve 3. A spring 4 is sleeved o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com