Battery cell precision calibration tool for formation and capacity grading equipment

A tooling and equipment technology, applied in the field of cell precision calibration tooling, can solve the problems of cluttered and unsightly exposed cables, inconvenient operation, inconvenient use, etc., and achieve the effect of meeting the requirements of quick change, convenient operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

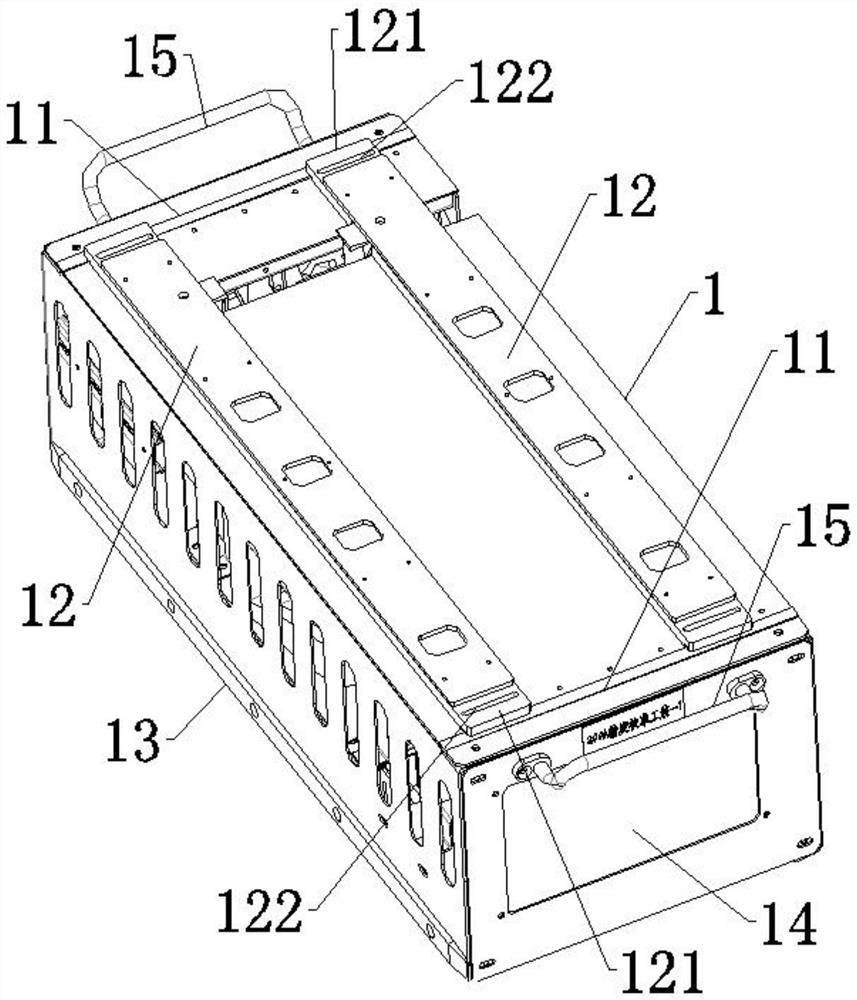

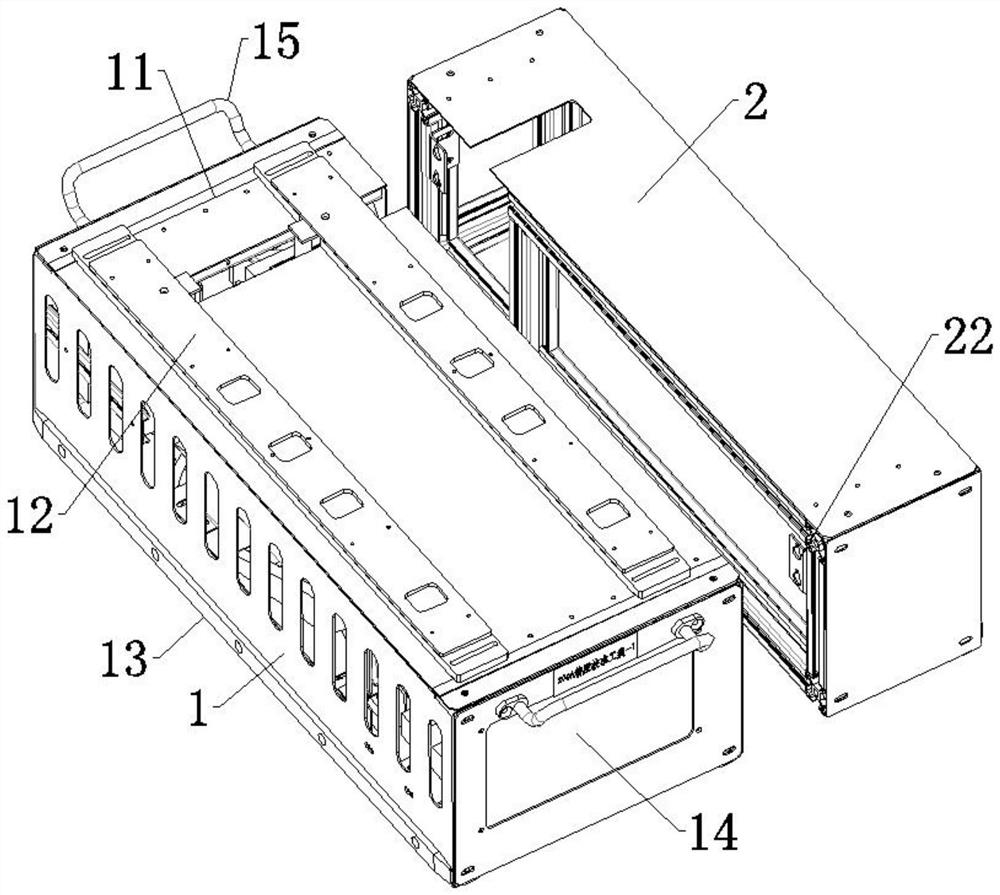

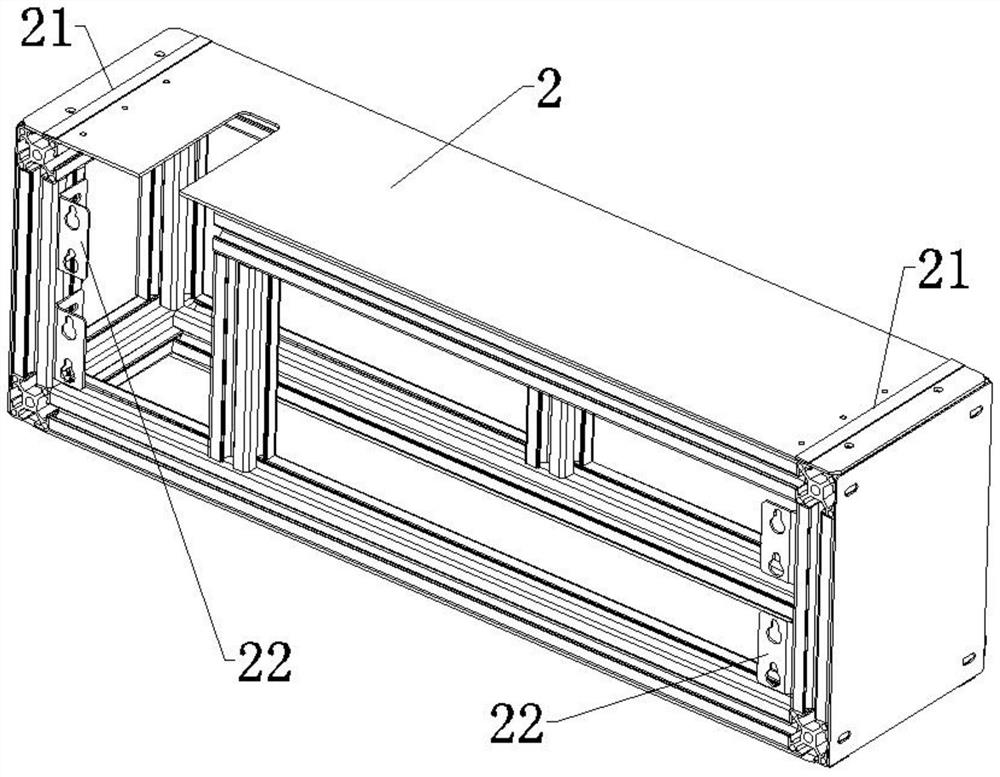

[0039] see Figures 1 to 7 As shown, the present invention provides a technical solution: a cell accuracy calibration tool for chemical composition capacity equipment, including:

[0040] The tooling box 1 is a fully enclosed ventilated hollow box with two calibration scales 11 and two electrode plates 12 on the top, and the two calibration scales 11 are arranged on the top of the tooling box 1 parallel to each other. On the opposite sides, both sides of each electrode plate 12 are fixed and locked between the calibration scales 11 on both sides through bolts that can be adjusted;

[0041] Two tooling guide strips 13 are also symmetrically installed on the tooling box body 1, and the tooling box body 1 can be separated and slid in the chemical composition container through the tooling guide strips 13;

[0042] The multimeter 3, the wireless router 32 and the printed circuit board 4 are all installed in the tooling box 1;

[0043] The power-taking socket 33 is fixed on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com