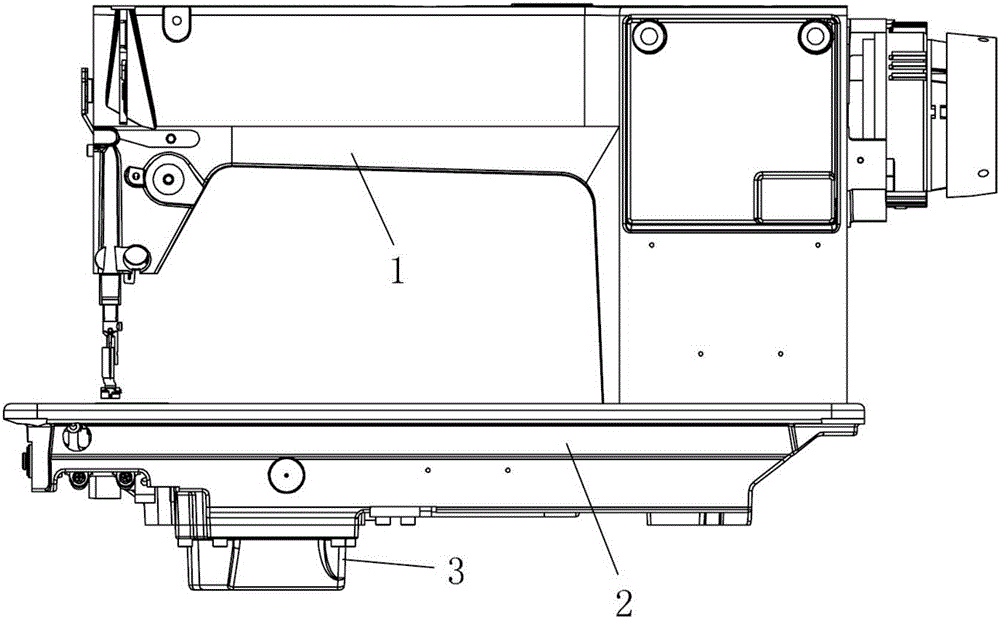

Lubrication system of sewing machine

A lubrication system and sewing machine technology, applied in the field of sewing machines, can solve the problems of physical influence, increased noise, unreasonable design of lubrication system, etc., and achieve effective lubrication, noise reduction, and good atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

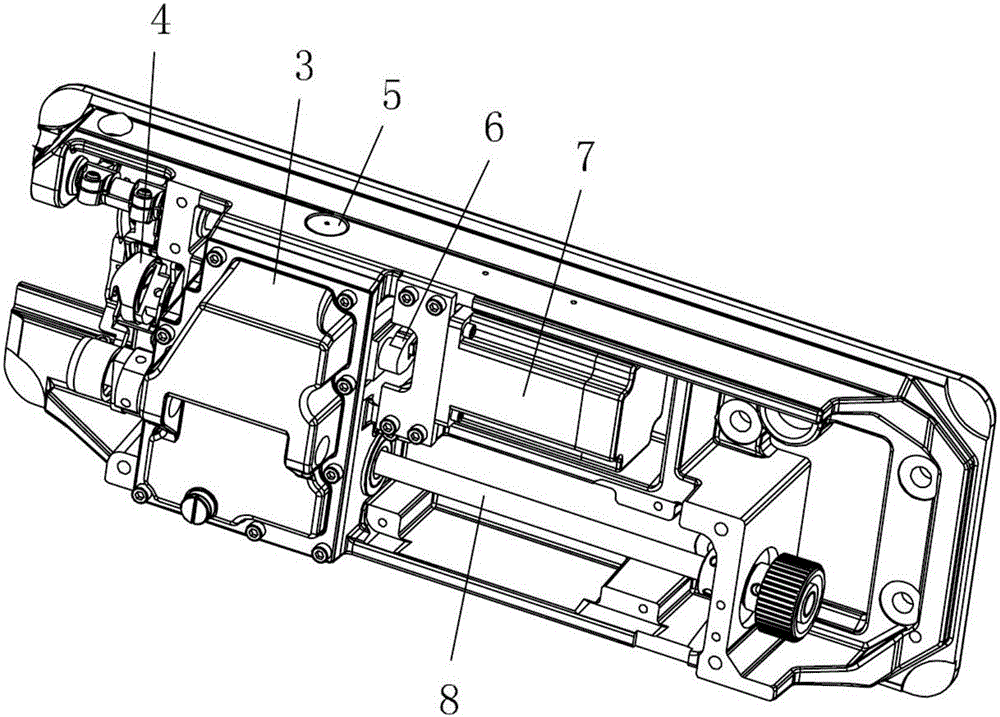

Method used

Image

Examples

Embodiment 2

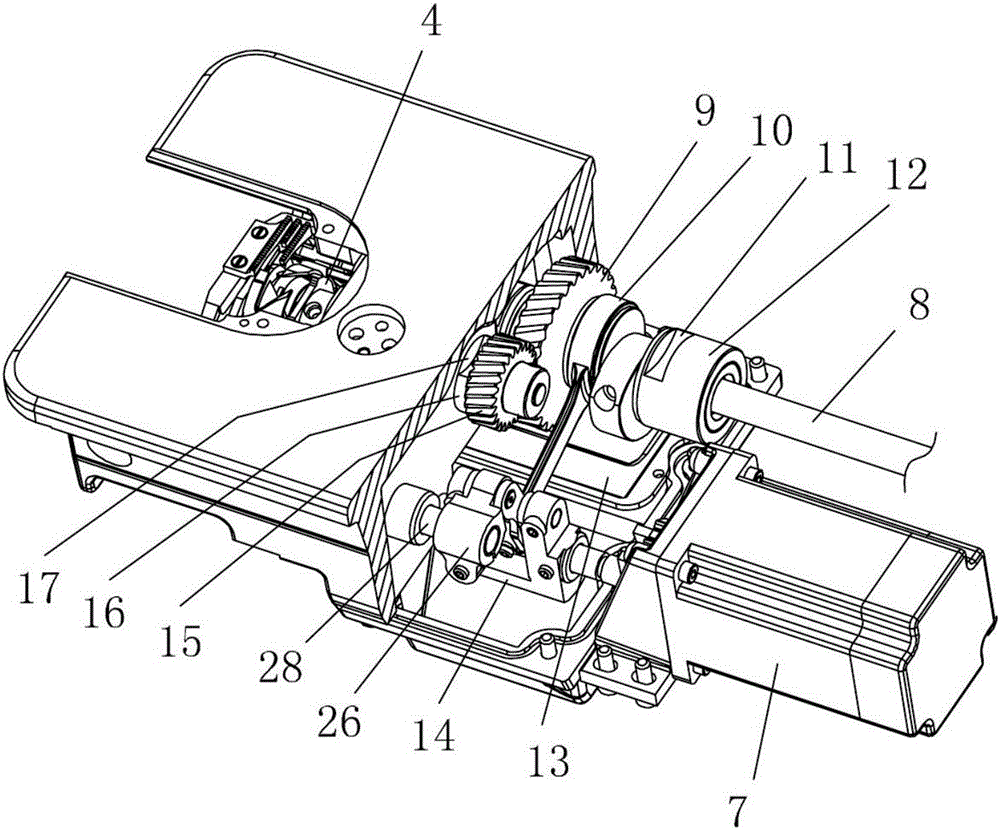

[0048] Embodiment 2, this embodiment is basically the same as Embodiment 1, the difference is that the first transmission mechanism includes a swing tooth crank 50, a swing plate seat 14, an eccentric part 1 49, a swing tooth connecting rod 48 and a sliding part 51; the tooth swing crank 50 is set on the tooth lifting cam seat, and the tooth lifting cam seat is fixed on the tooth lifting shaft 8, and the other end of the tooth swing crank 50 is hinged with a slider 51, and the slider 51 is slidably arranged on the swing In the chute 52 of the board seat 14. The other side of the sliding member 51 is hinged with a swing tooth connecting rod 48, and the other end of the swing tooth connecting rod 48 is hinged with the eccentric part one 49 sleeved on the swing tooth shaft 28; one end of the eccentric part one 49 is provided with a through hole, through which the bolt lock Fastening is connected on the swing tooth shaft 28;

[0049] One end of the sliding groove 52 is fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com