Novel oilfield flow string fixing device and use method

A technology of fixing device and oil production pipe, which is applied in the direction of pipeline support, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of unsatisfactory use effect and inability to adjust oil production pipe string in oil field, and achieves firm and safe support. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

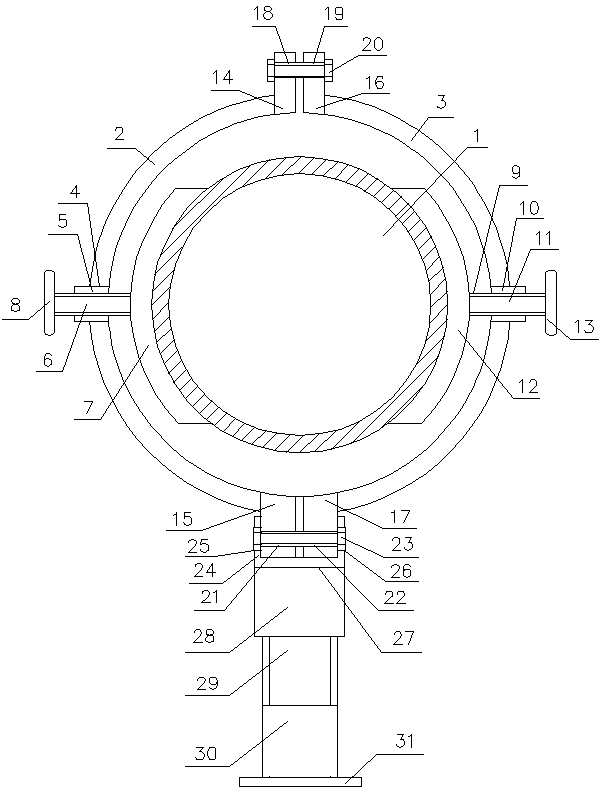

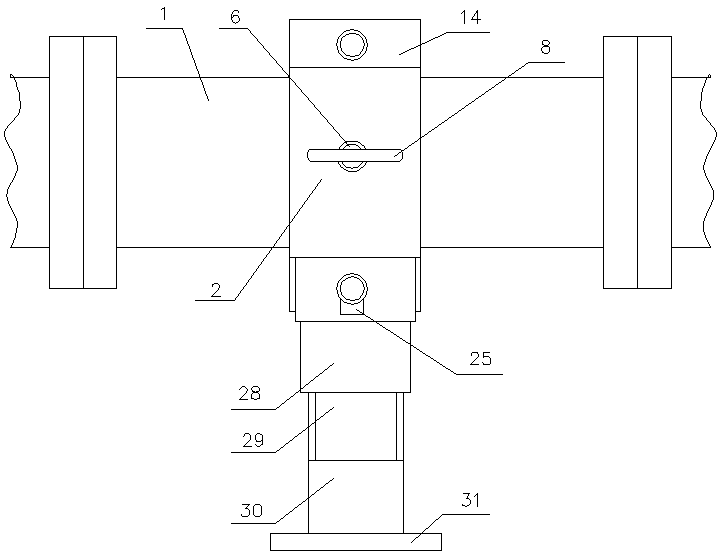

[0018] A novel oilfield oil production pipe string fixing device, which consists of: an oilfield oil production pipe string 1, the oil field oil production pipe string is provided with a front arc pinch plate 2 and a rear arc pinch plate 3, and the front arc pinch plate Buckle the oilfield oil production string with the rear arc pinch plate, there is a gap between the front arc pinch plate, the rear arc pinch plate and the oil field oil production string, the The front arc-shaped buckle plate has a front threaded hole 4, the front threaded hole is welded with a front threaded sleeve 5, the front threaded sleeve is connected with a front threaded rod 6, and the front end of the front threaded rod is welded with a front fastening arc Splint 7, the rear end of the front threaded rod is welded to the front adjusting rod 8, the rear arc-shaped pinch plate has a rear threaded hole 9, the rear threaded hole is welded to the rear threaded sleeve 10, and the rear threaded The sleeve is...

Embodiment 2

[0020] In the novel oil production tubing string fixing device described in Embodiment 1, the top of the front arc pinch plate is fixedly connected to the front top splint 14 and the front bottom splint 15, and the top of the rear arc pinch plate is fixedly connected to the rear top splint. Clamping plate 16 and rear bottom splint 17, described front top splint has front top through hole 18, and described rear top splint has rear top through hole 19, and described front top through hole and described rear top pass through The holes are connected by top bolts 20, the front bottom splint has a front bottom through hole 21, the rear bottom splint has a rear bottom through hole 22, the front bottom through hole and the rear bottom The through holes are connected by bottom bolts 23 . The front top splint, the front bottom splint, the rear top splint, and the rear bottom splint can clamp and fix the oil field production string by clamping the front arc pinch plate and the rear arc p...

Embodiment 3

[0022] In the novel oil production tubing string fixing device described in Embodiment 2, the front bottom splint and the rear bottom splint are inserted into the U-shaped insert 24 at the same time, and the front side of the U-shaped insert is provided with a front card slot 25 , one end of the bottom bolt snaps into the front slot, the rear side of the U-shaped insert has a rear slot 26, and the other end of the bottom bolt snaps into the rear slot Inside, the bottom of the U-shaped plug-in has a plane 27, and the bottom of the plane is welded with a vertical screw sleeve 28, and the vertical screw sleeve is connected with an adjustment stud 29, and the adjustment stud is connected with a support column 30, so that The support column described above is connected to the fixed base plate 31, and the described fixed base plate is placed on the ground.

[0023] The shape plug-in can connect the front bottom splint and the rear bottom splint, and it is more firm and safe to be cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com