Display panel driving method, system and display device

A technology of display panel and driving method, applied in static indicators, instruments, etc., can solve problems such as cost increase, inability to reach agreement on impedance in sector area, cost problems, etc., and achieve the effect of improving chromatic aberration and improving optical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

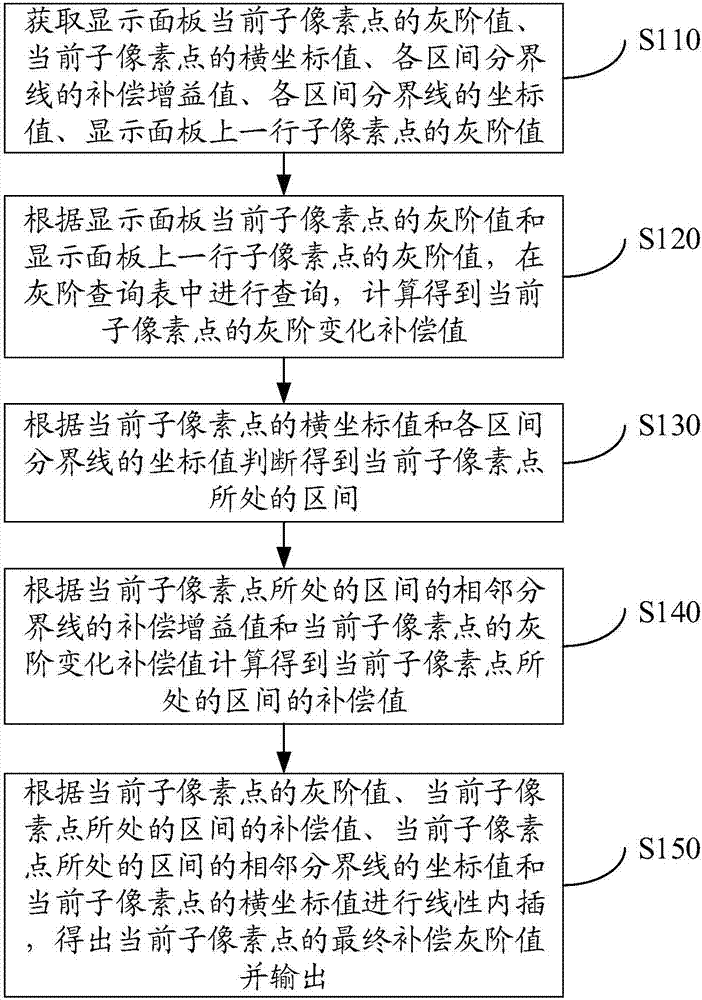

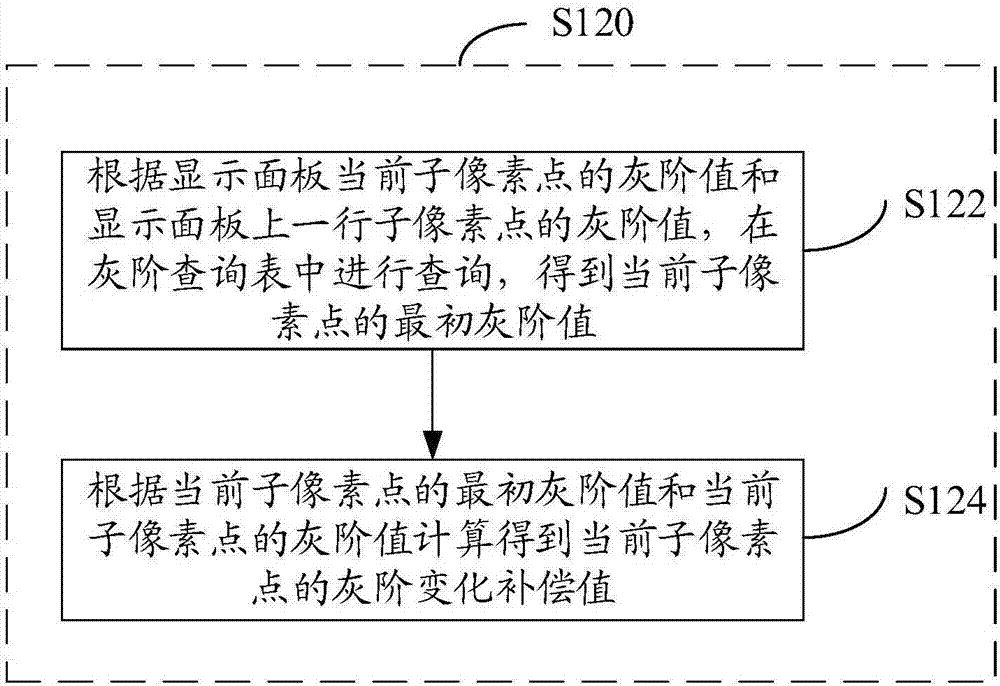

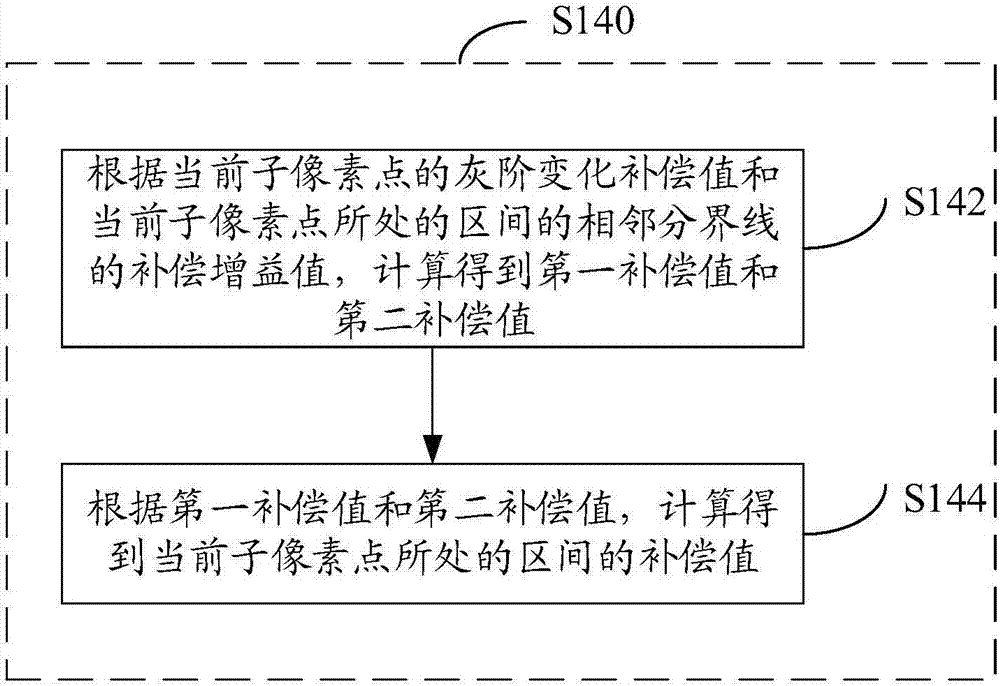

[0025] In one embodiment, such as figure 1 As shown, a display panel driving method includes the following steps:

[0026] Step S110: Obtain the gray scale value of the current sub-pixel point of the display panel, the abscissa value of the current sub-pixel point, the compensation gain value of the boundary line of each interval, the coordinate value of the boundary line of each interval, and the grayscale value of a row of sub-pixel points on the display panel. order value.

[0027] Specifically, the compensation gain value of the boundary line of each interval is obtained through debugging and measurement with the actual panel type. The corresponding relationship between a row of sub-pixels on the display panel and the current sub-pixel is that when the grayscale compensation is performed according to the preset order in the preset direction, a compensated sub-pixel is on the current sub-pixel. In this embodiment, the display panel Perform chromatic aberration compensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com