Electric pressure cooker and upper cover assembly of electric pressure cooker

An electric pressure cooker and lid assembly technology, which is applied to pressure cookers, cooking utensils, household appliances, etc., can solve the problems of damaged rotary chuck operation, inconvenient operation of electric pressure cookers, low safety and reliability, etc., and achieves stable installation and improved operation reliability. The effect of improving, improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

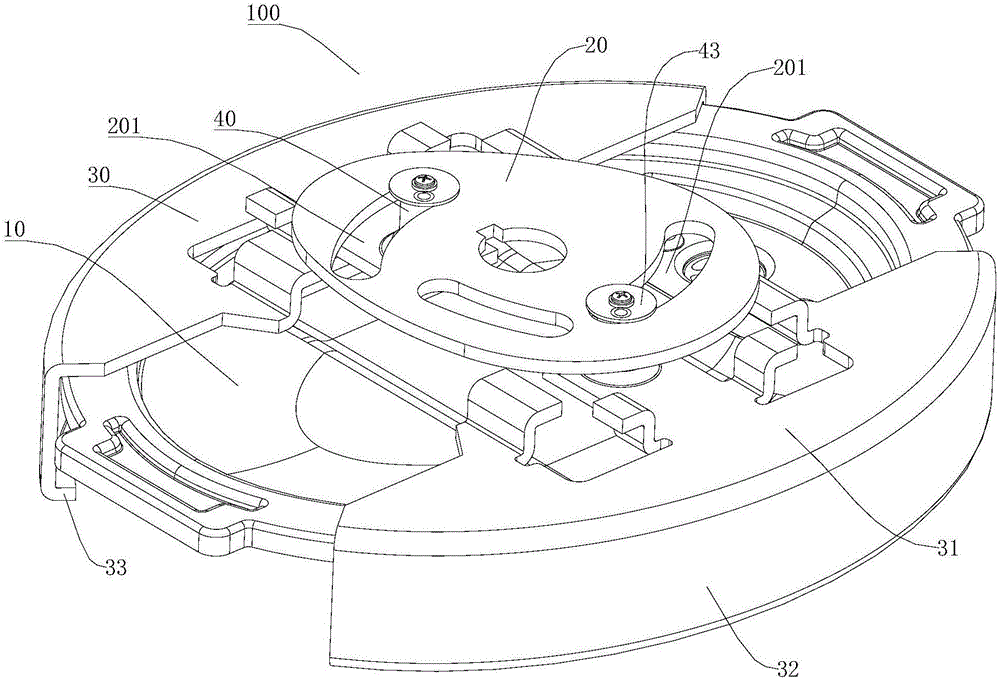

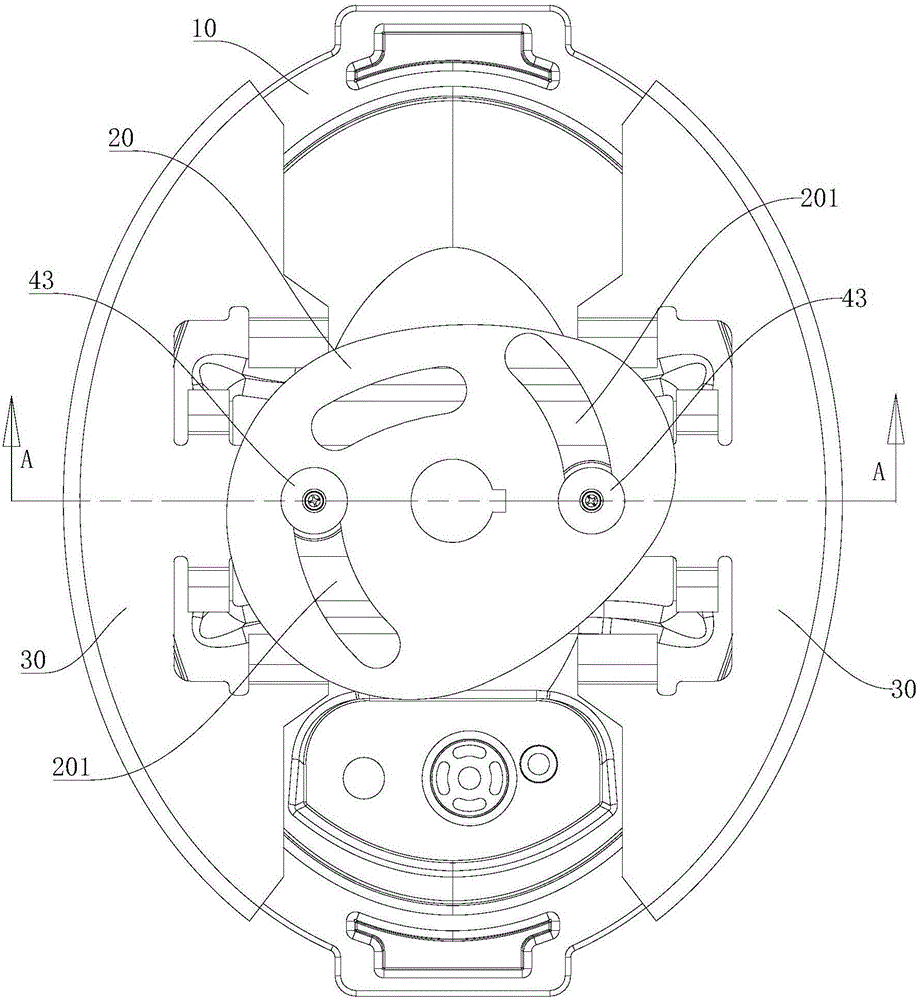

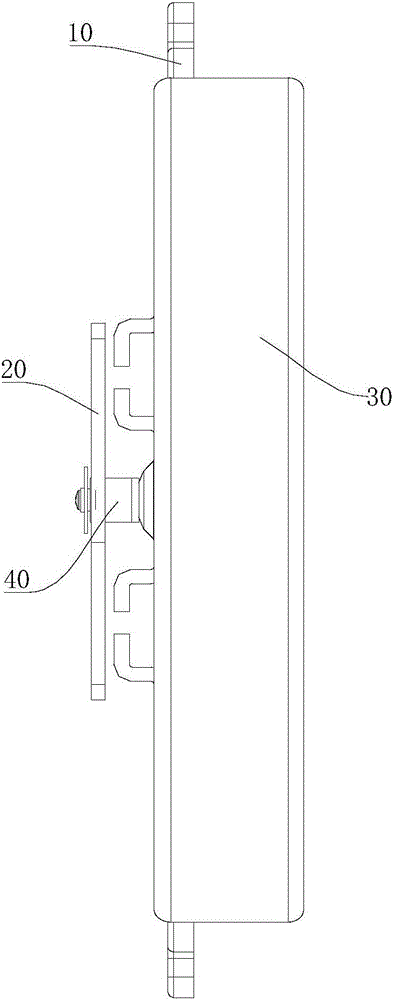

[0042] The upper cover assembly 100 of the electric pressure cooker according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0043] refer to Figure 1 to Figure 14 As shown, the upper lid assembly 100 of the electric pressure cooker according to the embodiment of the present invention may include an upper lid body 10 , a rotary chuck 20 , two fastening elements 30 , two pillars 40 and two elastic elements 50 . Of course, the number of snap-fitting parts 30, struts 40 and elastic parts 50 is not limited thereto, and can be set according to specific conditions, but the number of snap-fit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com