A Displacement Profile Correction Method of Scroll Machine

A vortex line and vortex technology, which is applied in the field of scroll machine displacement profile correction, can solve problems such as reducing the displacement of scroll compressors, achieve reduced exhaust loss, high comprehensive performance, and increase exhaust volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments will be described in detail below in conjunction with the accompanying drawings.

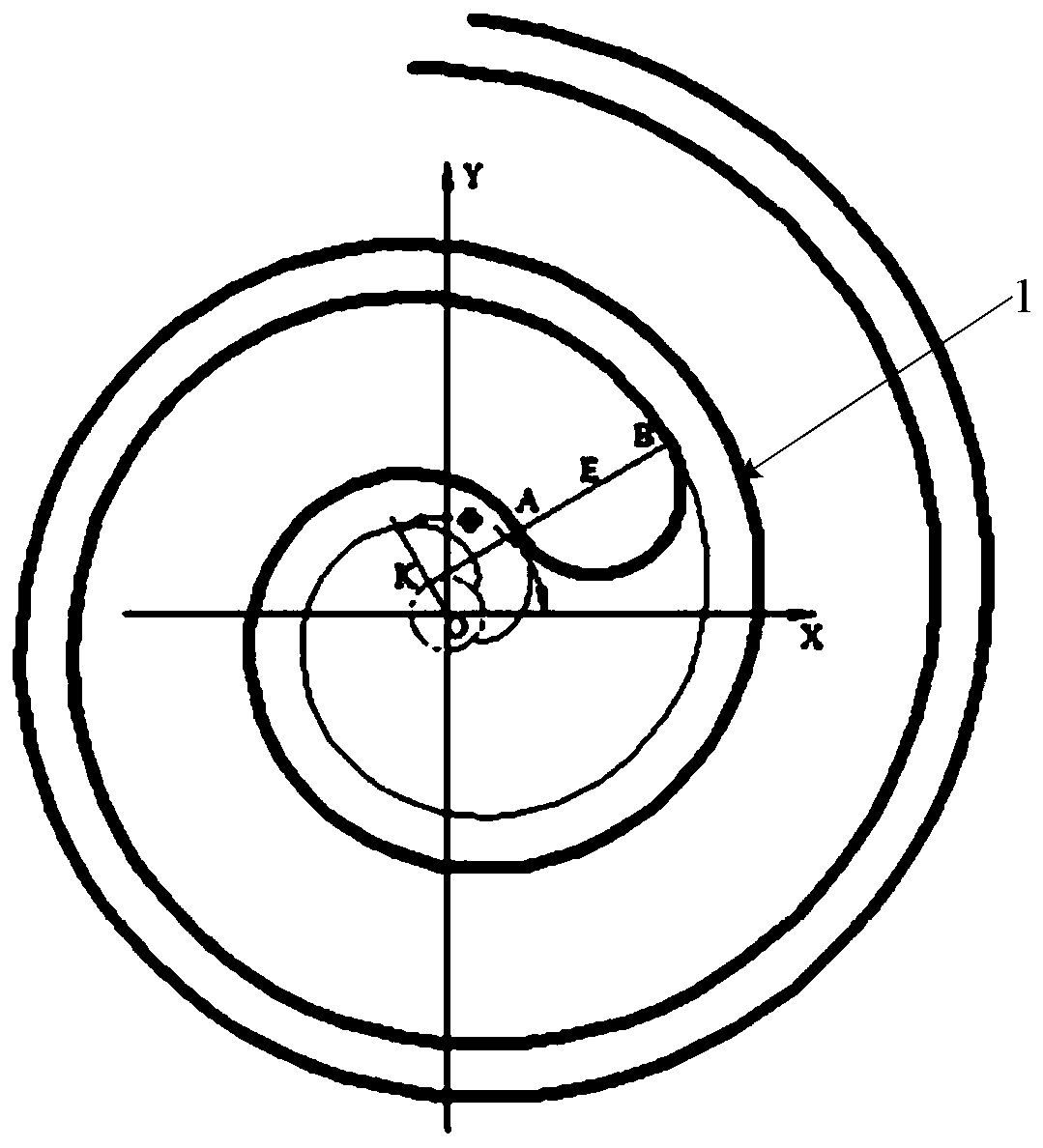

[0019] See attached figure 1 , the movable scroll 1 molded line is corrected, the coordinate system is established with the center of the base circle O as the origin, the inner molded line and the outer molded line are drawn according to the orbital scroll gear parameters of the movable scroll 1, and the development angle Φ is used as the development line and the movable scroll 1 The outer molded line of the scroll line intersects at point A, and the inner molded line of the scroll line of the movable scroll 1 intersects at point B. With the midpoint E of AB as the center and EA as the radius, an arc is drawn, which is the movable scroll 1 The single-arc modified profile, the spread angle of the involute from point A is Φ, and the spread angle of the involute from point B is Φ+2π.

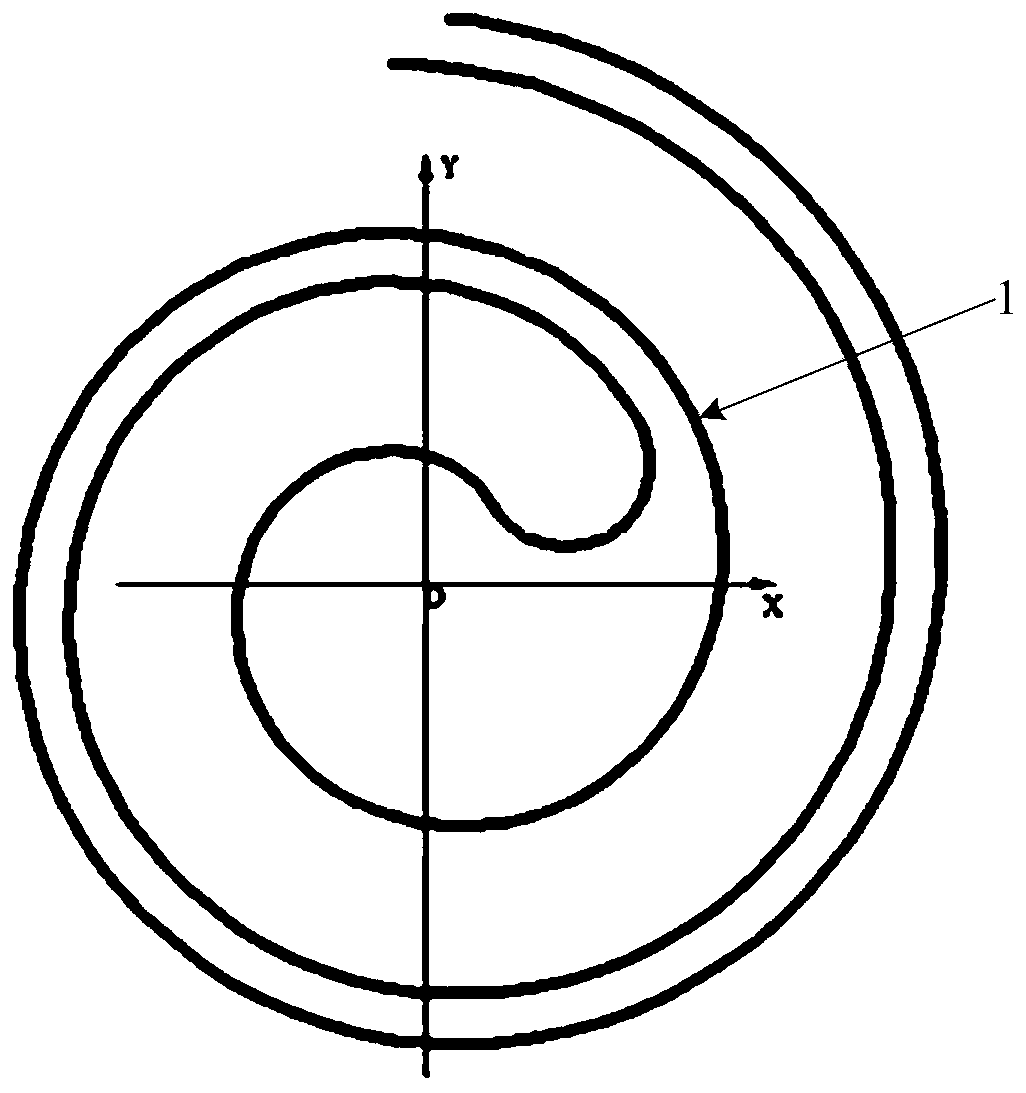

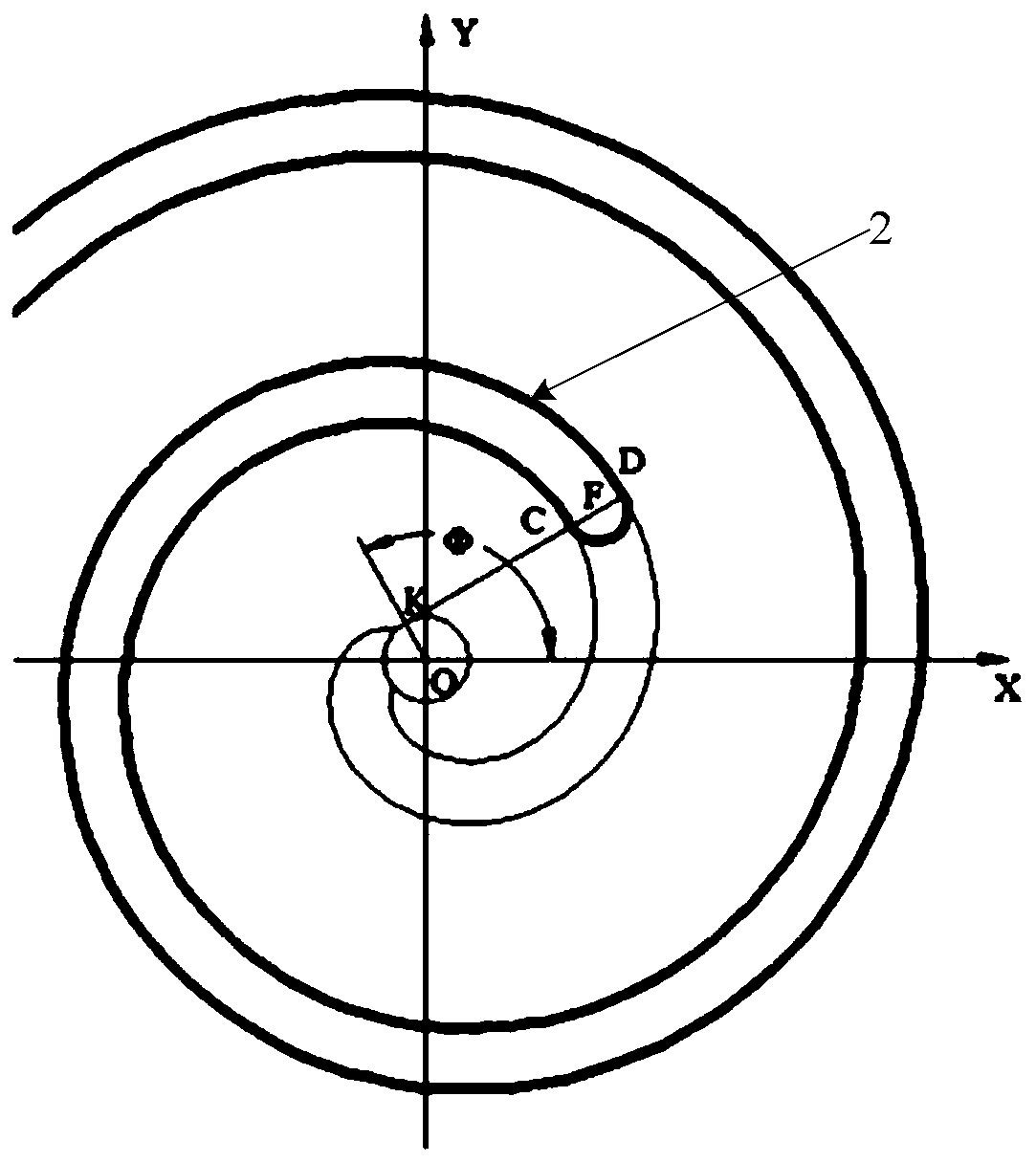

[0020] See attached figure 2 , The scroll tooth profile diagram after the modification o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com