Step-type mixed gas steel cylinder

A mixed gas, step-type technology, applied in the field of gas cylinders and cylinders dedicated to mixed gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles and features of the patent of the present invention are described below in conjunction with examples, which are only used to explain the patent of the present invention, and are not used to limit the scope of the patent of the present invention.

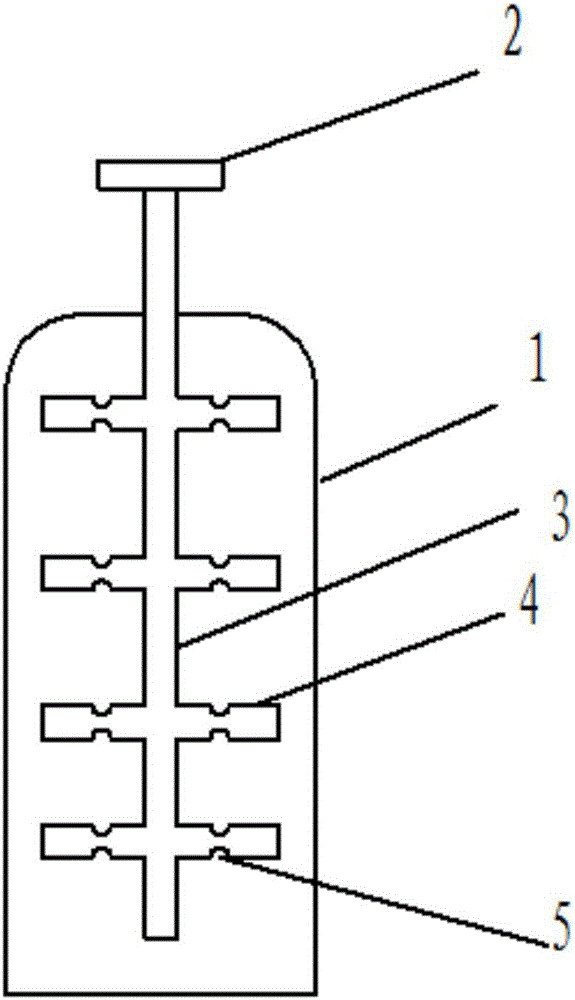

[0014] A special steel cylinder for a stepped mixed gas, comprising a gas valve 2 arranged at the top of the cylinder body at the first stage of the steel cylinder body, and a ladder-shaped long tube main branch 3 extending to the bottom of the steel cylinder body at the air inlet of the steel cylinder body, and the main branch of the long tube is The bottom end of the branch is not closed, and there is still an air outlet. The main branch of the long pipe is provided with 4 transverse branches 4 with air holes at the end. The angle between the branch 4 of the long pipe and the main branch 3 of the long pipe is 90 degrees. , the transverse branch 4 is provided with air holes 5, and the air holes 5 are mirror-symm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap