Passive type load simulator and superfluous torque suppression method

A load simulator, passive technology, applied in the direction of electric controllers, controllers with specific characteristics, etc., can solve problems affecting system stability, etc., to improve the utilization of weight space, improve robustness and tracking accuracy, The effect of improving loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

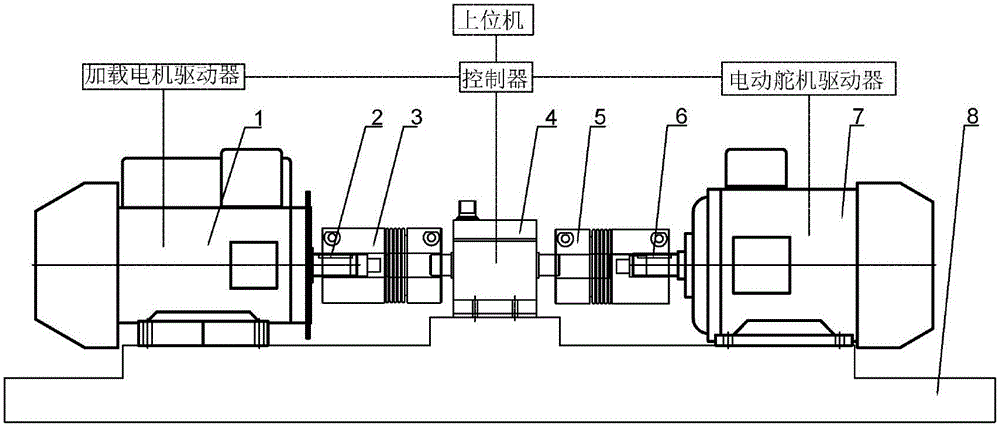

[0118] In order to verify the present invention, the selected loading motor 1 of the embodiment is the AKM53H-320VDC of Kollmorgen, the torque speed sensor 4 is Interface T3 30Nm, the electric steering gear 7 is KZZ-83, and the controller is the NI PXIe-8840RT real-time controller;

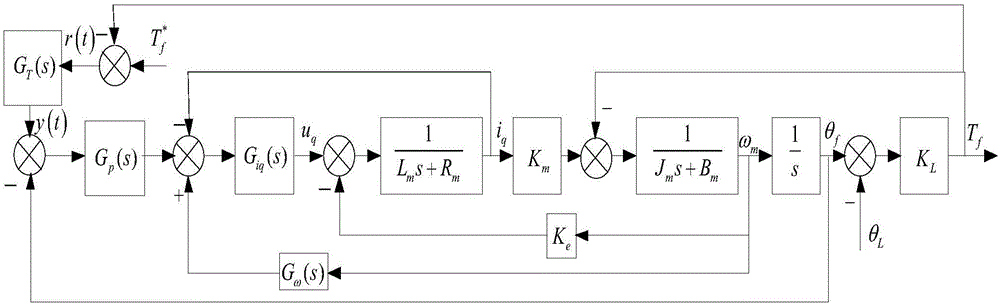

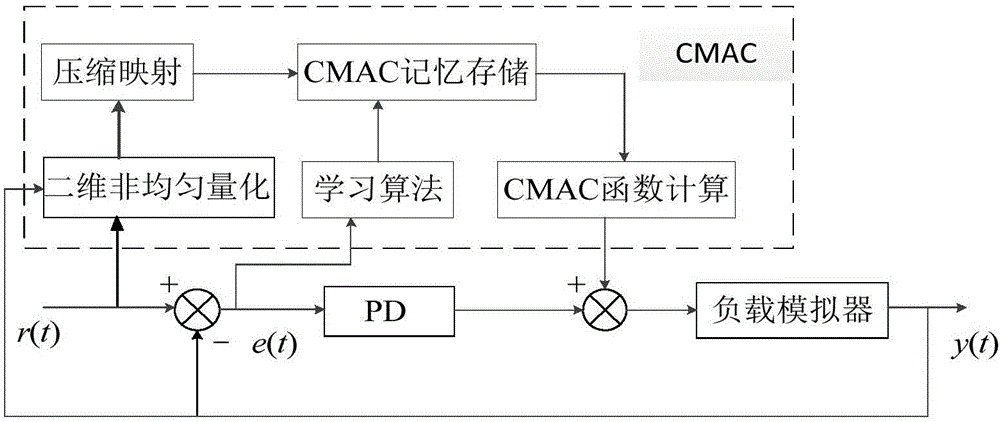

[0119] In order to compare and verify the suppression effect of excess torque, this method is compared with the commonly used disturbance feed-forward compensation method based on the principle of structural invariance. The control block diagram of the principle of structural invariance is as follows: Figure 4 as shown, Figure 4 middle, T r * (s) is the input of the system, T L (s) is the output, the forward channel is controlled by G 1 (s), G 2 (s), G 3 (s) Composition, G c (s) is a feed-forward compensation controller; set the current loop G iq (s) The controller parameter is: K CP =3.6,K CI =320,K Cω =1000; set position ring G p (s) The controller parameter is: P 1 =1.62,I 1 =0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com