Rack and pinion hydraulic pressure horizontal loading retraction and extending test table mechanism

A horizontal loading, rack and pinion technology, applied in the field of landing gear testing, can solve the problems that the height of the large-sized landing gear cannot be satisfied, the direction of the force is always consistent, and the speed of the landing gear cannot be satisfied, etc., and the pulling line is simple and clear. Compact structure and the effect of suppressing excess torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

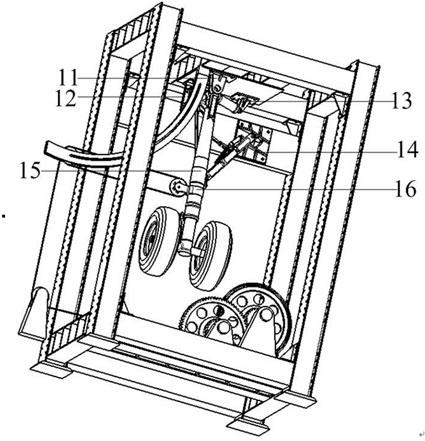

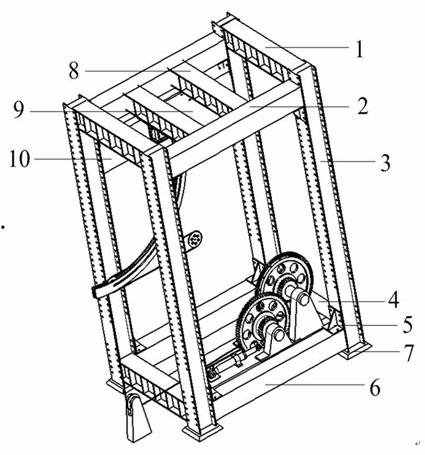

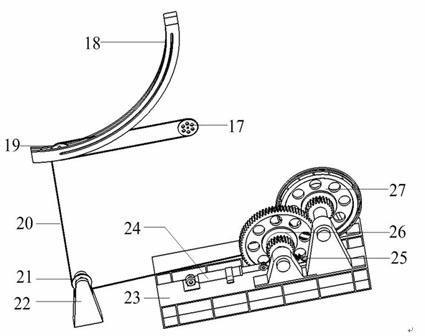

[0028] The rack-and-pinion hydraulic horizontal loading retractable test bench mechanism of the present invention:

[0029] Including the column frame, the upper connecting seat 8 and the lower connecting seat 23 installed on the column frame, the lower surface of the upper connecting seat 8 is also equipped with a hanging plate 9 for installing the landing gear 15; The loading actuator 24, the rack 25 installed on the lower connection seat 23 and connected with the loading actuator 24, the reduction gear 26 installed on the lower connection seat 23 and meshed with the above-mentioned rack 25 for transmission, installed on the lower connection The interlocking wheel disc 27 on the seat 23 and meshed with the above-mentioned reduction gear 26 constitutes a hydraulic loading and deceleration mechanism; it also includes the first movable pulley 17 fixedly installed on the center of gravity of the main pillar of the landing gear 15 through the first movable pulley fixture 16 axles,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com