A device for simultaneously mounting curved surface loads and plane loads

A load and curved surface technology, which is applied in the field of outer wall fixing devices, can solve problems such as inability to connect, and achieve cost savings and structural advantages.

The effect of simple structure and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be further described in conjunction with embodiments and drawings:

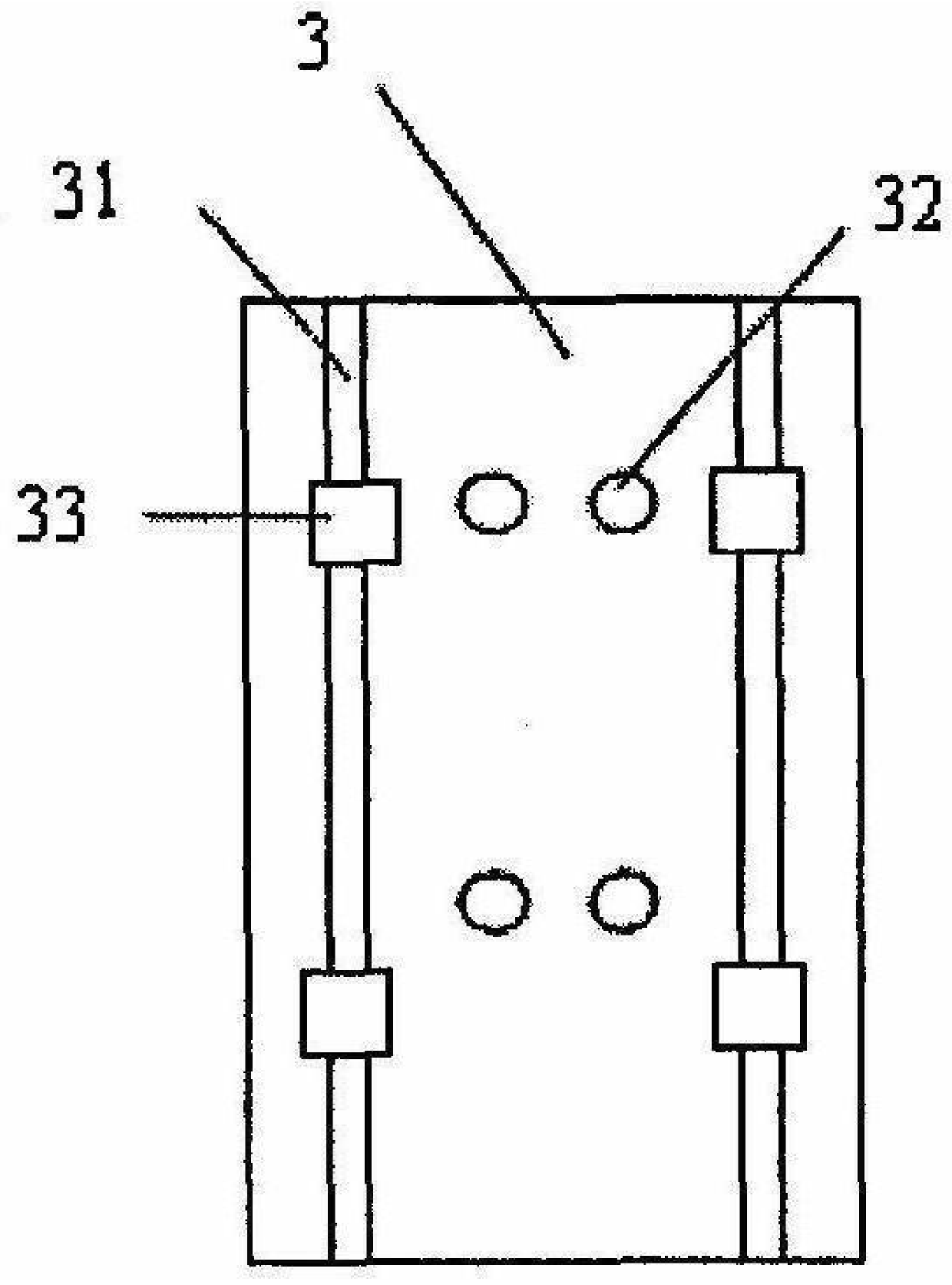

[0018] The positioning plate of the outer wall fixing device is provided with a positioning rod and a slider for fixing the plane load.

[0019] The positioning pin of the support frame corresponds to the screw hole of the fixing plate, and the positioning pin is located on the screw of the fixing plate in the free state.

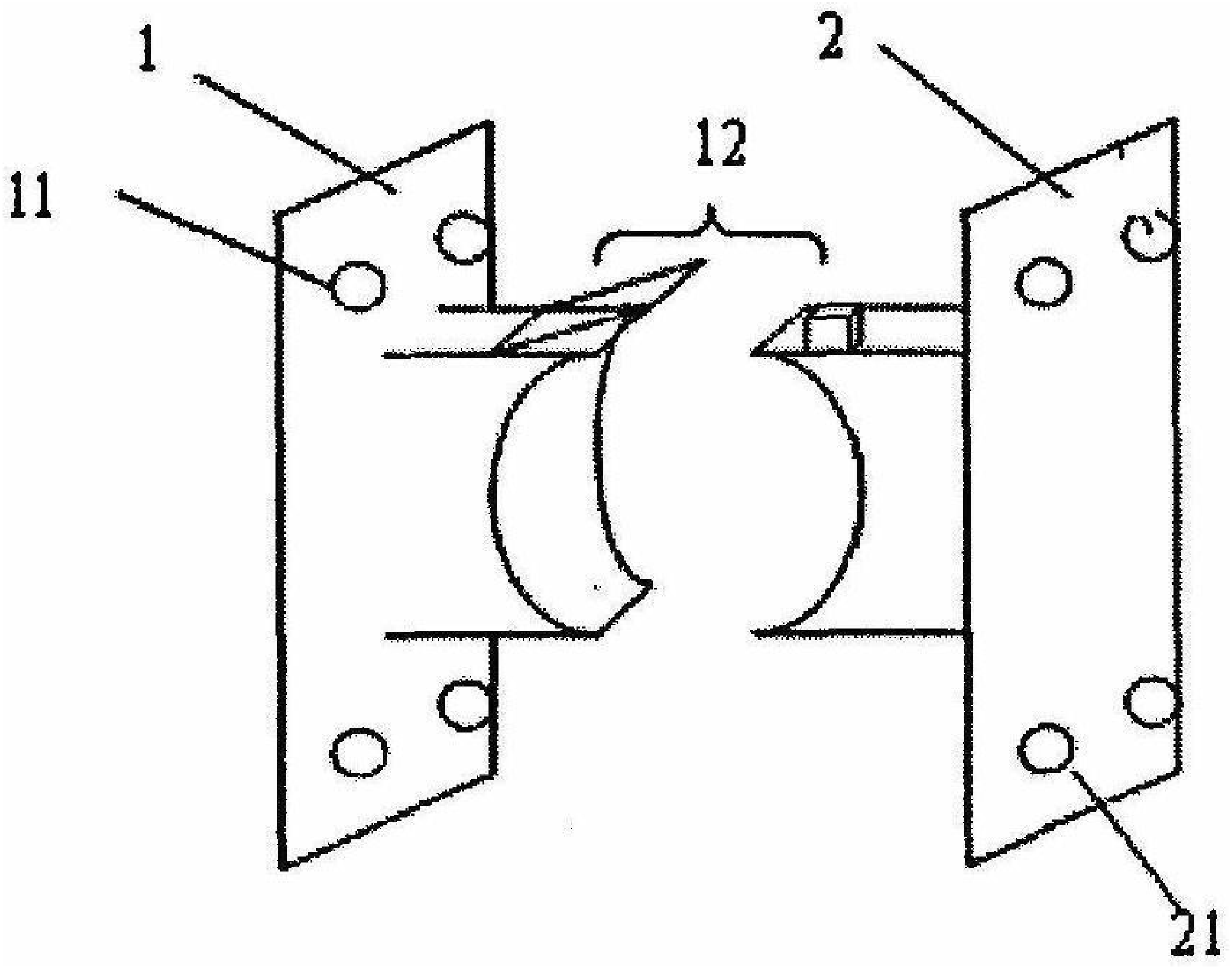

[0020] The buckle and the hinge are arranged on the outer wall of the through hole of the support frame, respectively located at 1 / 2 of the upper and lower side walls of the support frame. Since

[0021] The positioning rod is provided on the outer wall of the fixed plate, and the sliding block is provided on the positioning rod and can slide freely.

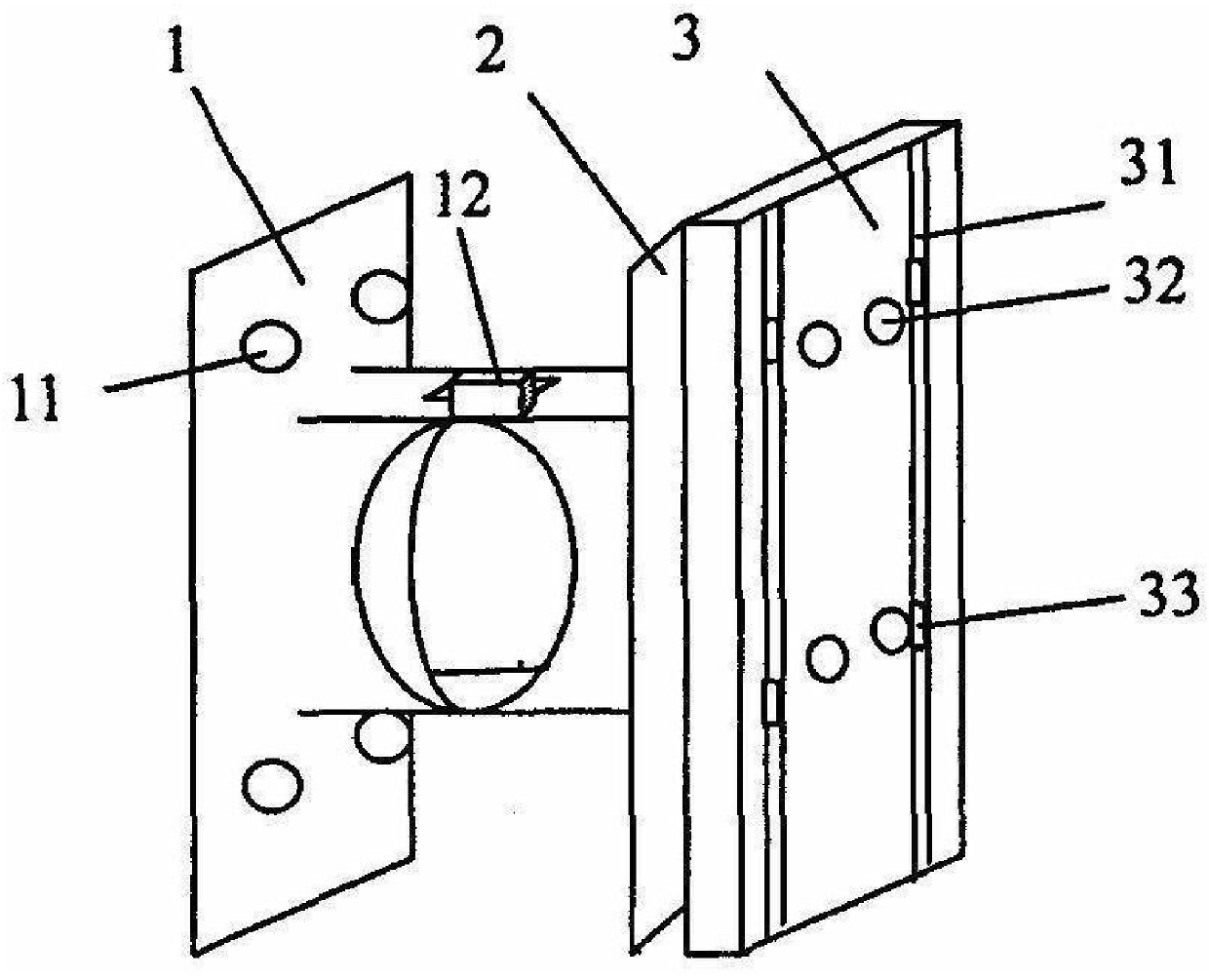

[0022] Please refer to FIG. 7, the outer wall fixing device of the present invention is installed on the outer wall 41 of the test body to realize the curved load 3 and

[0023] Please also refer to FIG. 2, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com