Train gripping mechanism of large roller coaster

A technology for grabbing mechanism and roller coaster, which is applied to entertainment, entertainment devices, slideways, etc., can solve the problems of high difficulty in car body processing, difficult maintenance of hook devices, and inappropriate lifting methods, so as to facilitate future maintenance and achieve remarkable results. Reliable, easy to apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

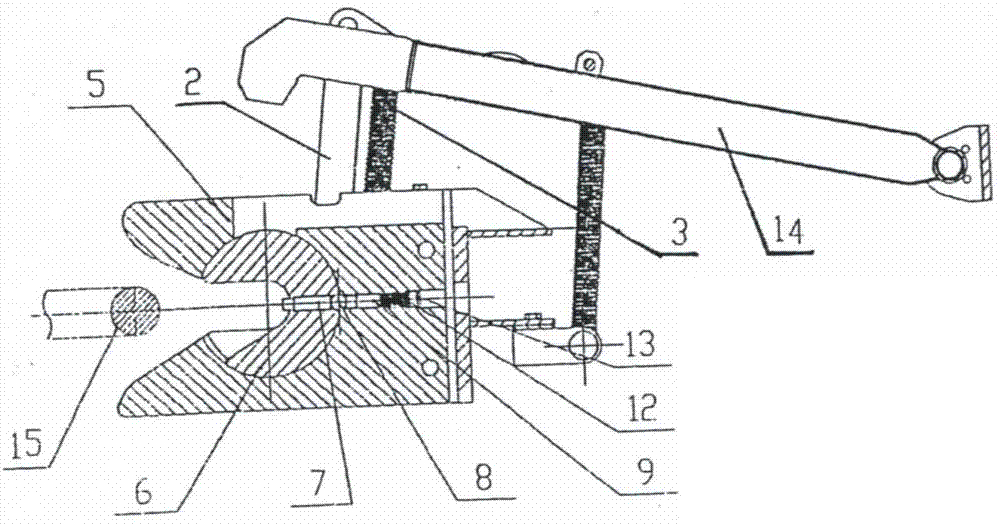

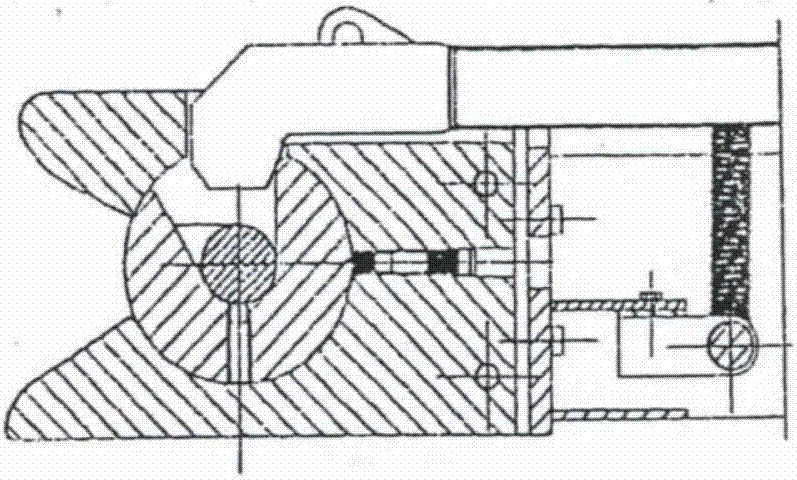

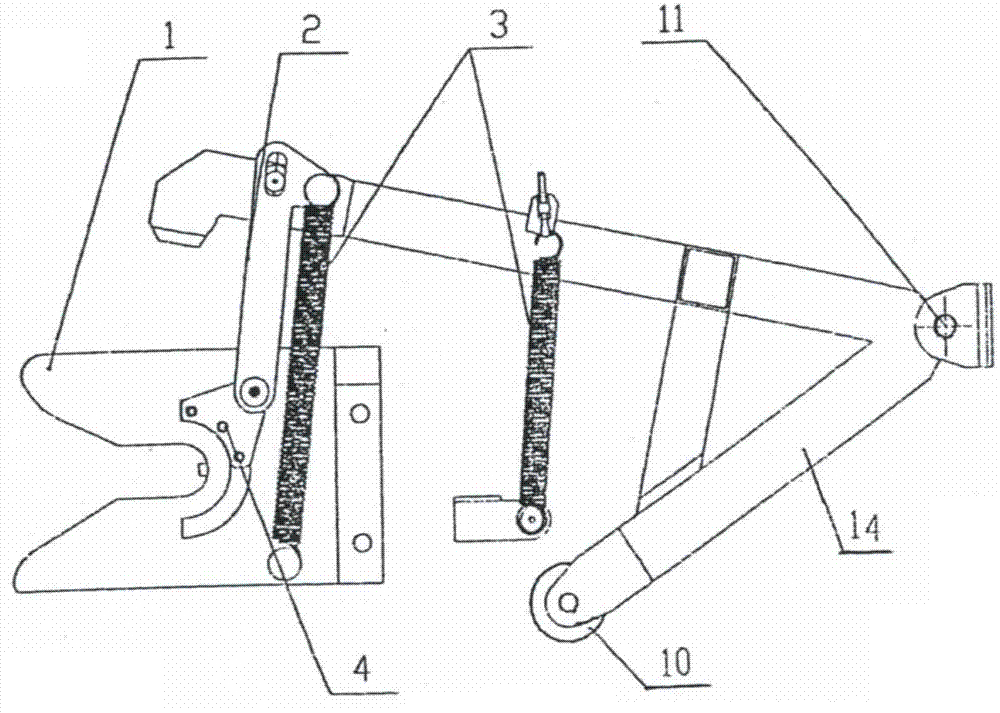

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 , 3, and 4 show:

[0034] A train grabbing mechanism for a large-scale roller coaster, which consists of a car body, a guard plate 1, a pull rod 2, a tension spring 3, a pull block 4, a hook head 5, a rotary block 6, a sliding pin 7, a ball 8, a top pin 9, and a runner 10. Rotating shaft 11, compression spring 12, screw 13, live support 14, pendant 15;

[0035] The train grabbing mechanism of the described large-scale roller coaster, its car body and the hook head 5 and the rotating shaft 11, the hook head 5 and the guard plate 1 are all fixedly connected, and its rotating shaft 11 is connected with the live support 14 in rotation, and the live support 14 is stretched out below The end and the running wheel 10 are connected flexibly by pivot pin rotation, and the upper middle position stretched out of its movable support 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com