Feeding device of numerical control drilling machine

A technology of feeding device and CNC drilling machine, which is applied in the direction of metal processing, etc., can solve the problems of inflexible use, troublesome operation of workers, and affecting work efficiency, etc., and achieve the effect of flexible use, easy operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

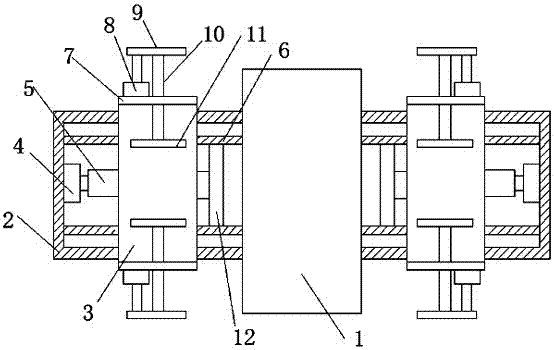

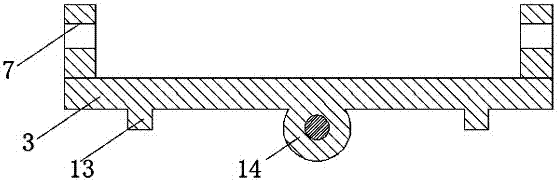

[0017] Reference Figure 1-2 , A feeding device for a numerically controlled drilling machine, comprising a drilling machine body 1, a feeding device is symmetrically provided on both sides of the drilling machine body 1, and the feeding device includes a mounting groove block 2, and a feeding table 3 is provided above the top of the mounting groove block 2 and installed The inner wall of the slot block 2 fixes the limit slot block 6, the inner wall of the installation slot block 2 away from the drilling machine body 1 is fixed with a drive motor 4 inside the limit slot block 6, and the output shaft of the drive motor 4 is fixed with a screw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap