Injection mold fixed mold side centripetal reversely-buckling corepulling device

An injection mold and undercut technology, which is applied in the field of core-pulling and demoulding devices, can solve the problems of high operation and maintenance costs, large mold shape, and many links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

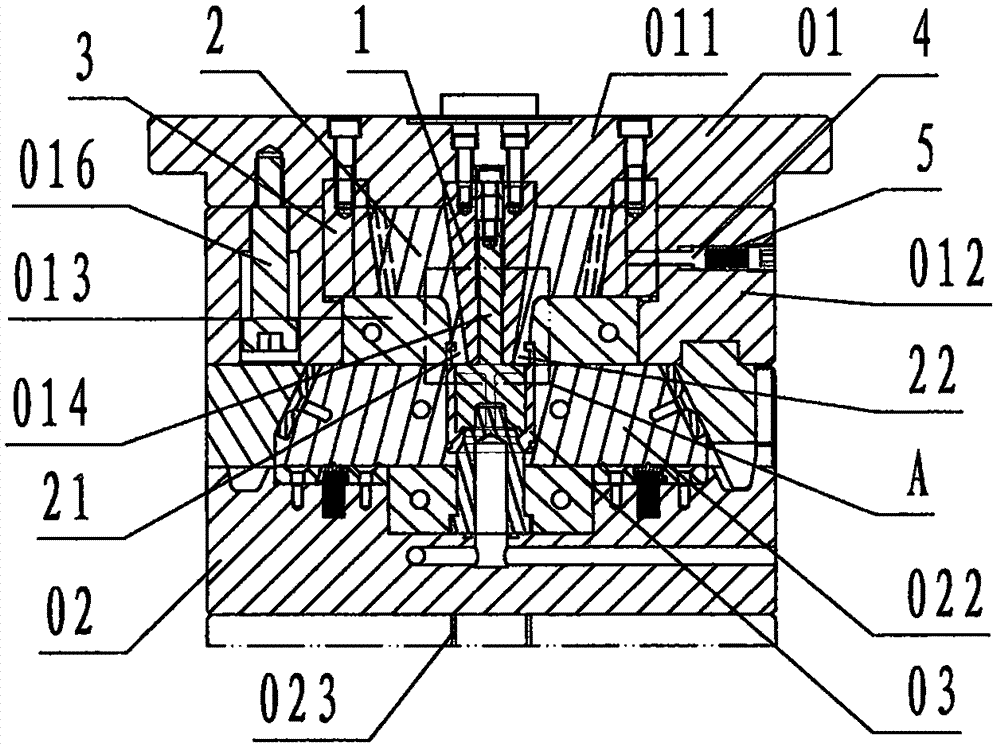

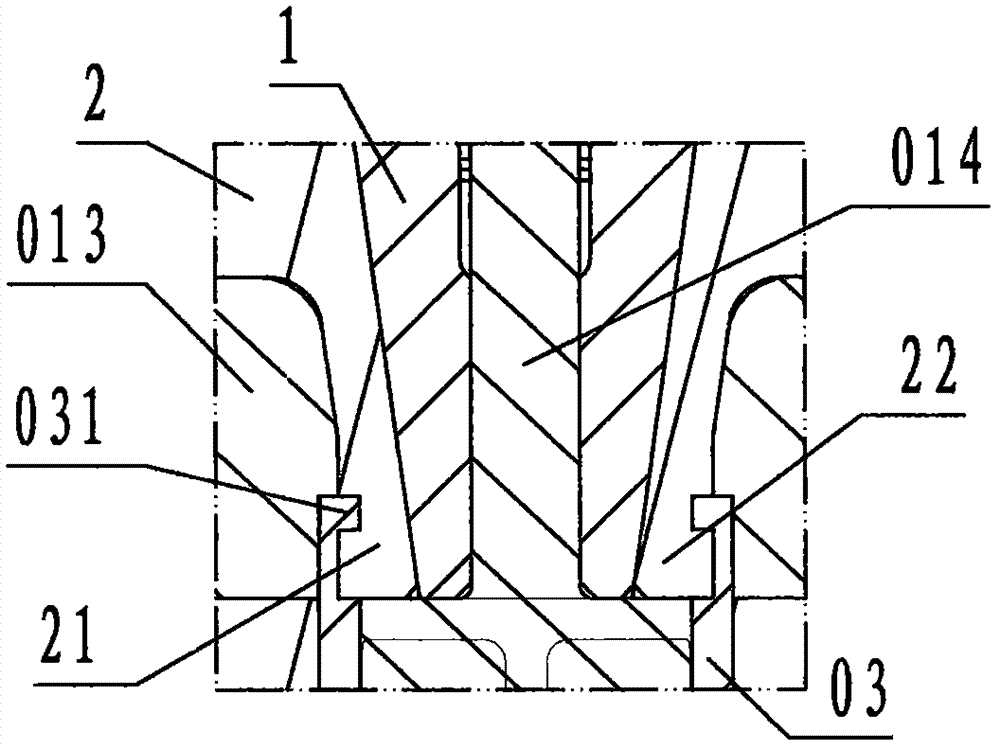

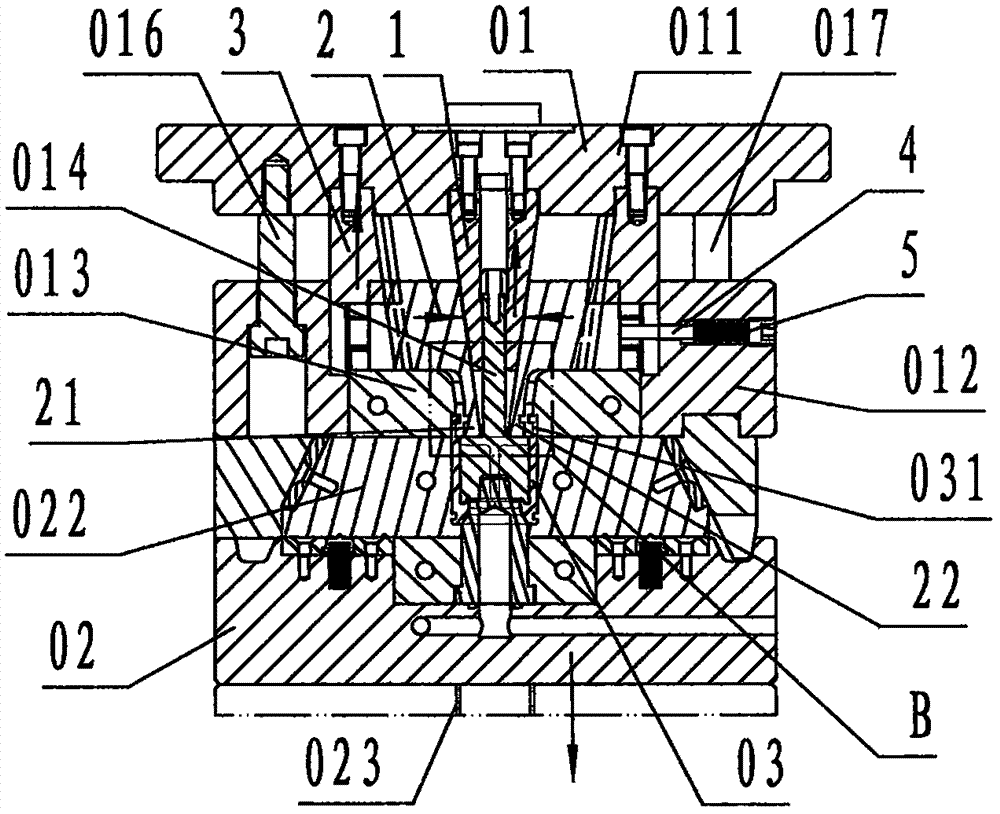

[0024] refer to Figure 1 to Figure 6 , an injection mold fixed mold side centripetal undercut core-pulling device of the present invention, comprising a central wedge 1, a centripetal undercut slider 2, a diagonal pull block 3, a booster rod 4, and a spring 5, wherein: the The central wedge 1 is a steel member with a trapezoidal shape with a large upper and a lower lower, and a steel member with a core slideway in the center;

[0025]The centripetal undercut slider 2 is a parallelogram-shaped steel member as viewed from the main view. Below the centripetal undercut slider 2, there are slide rails in the left and right directions and a T-shaped cross section called cross rails. The centripetal undercut sliders 2 that are symmetrical to each other on the left and right are respectively called the left slider and the right slider; the bottom right side of the left slider is provided with a left buckle end 21 of a molded product 03 opening to the right undercut structure. The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com