An articulated aluminum alloy EMU body chassis end structure

An end structure and aluminum alloy technology, which is applied in the field of rail vehicle body structure, can solve the problems such as the inability to meet the installation and connection of new bogies, and achieve the effect of reducing the weight of the whole vehicle and the running resistance of the train, reducing the use, and having good bearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

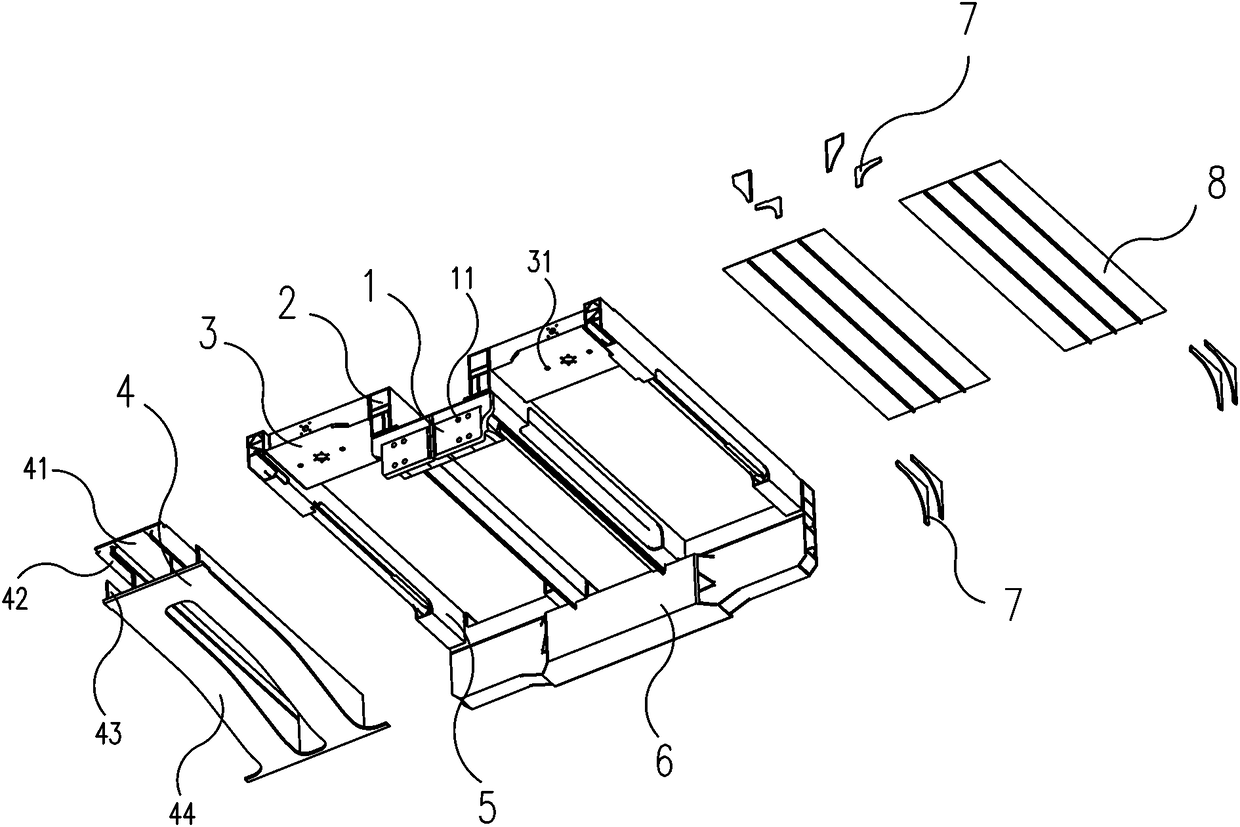

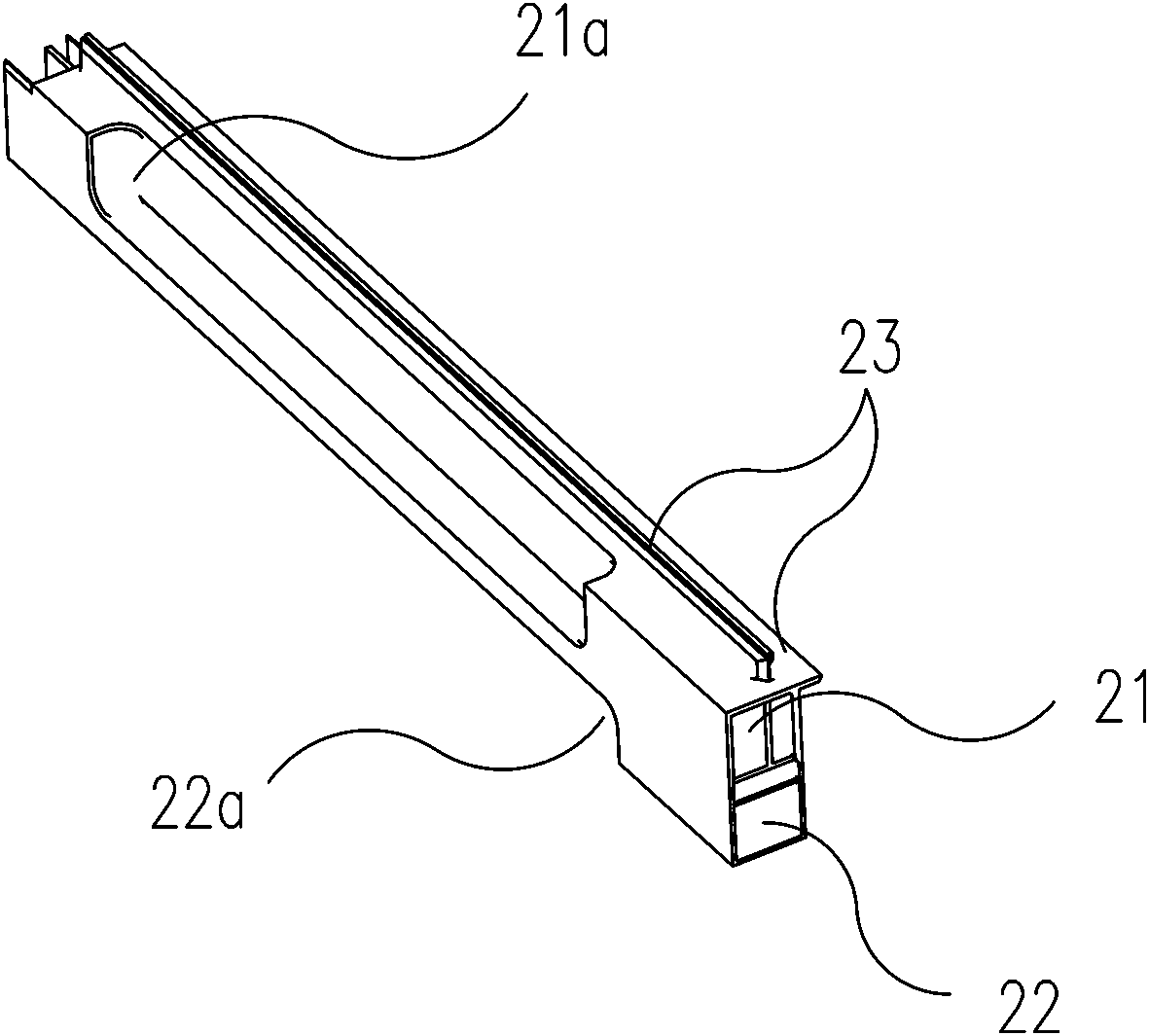

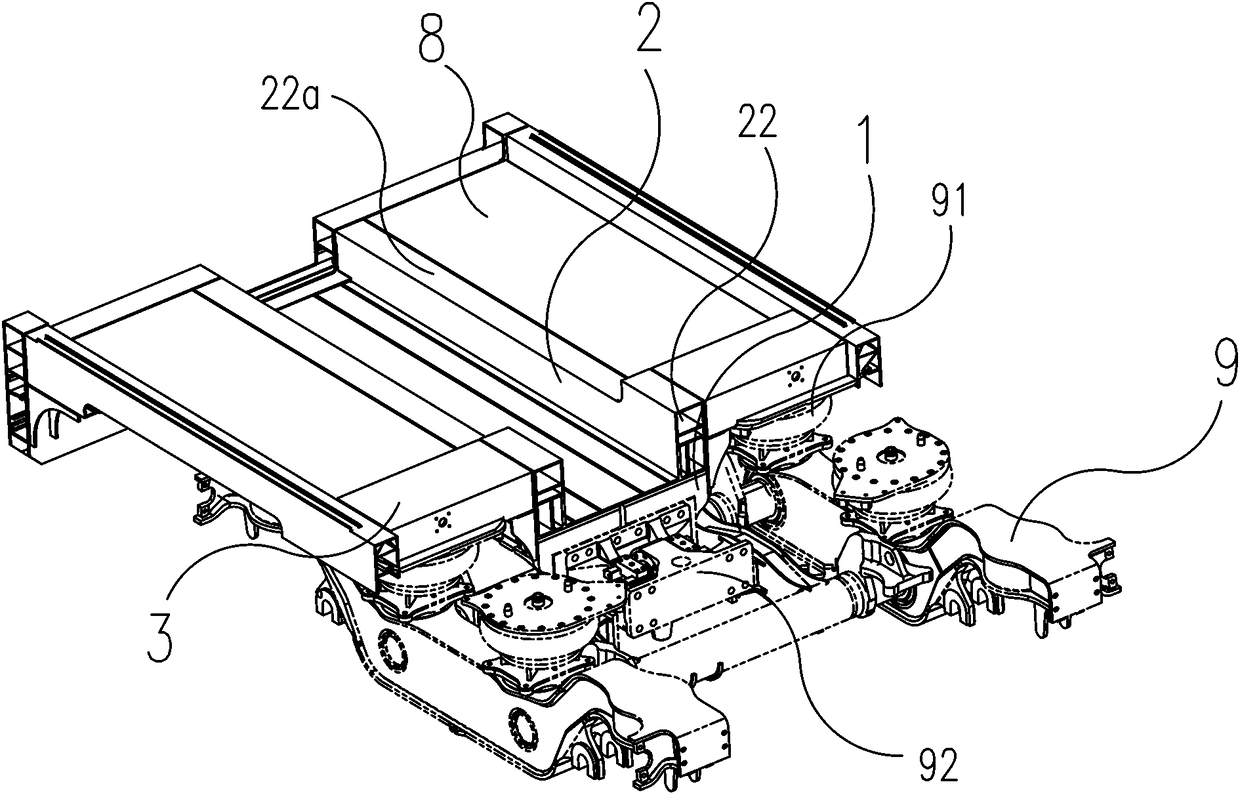

[0036] The main components of the bottom frame end structure of the present invention are as follows: figure 1 and figure 2 As shown: the overall frame structure of "mesh" is composed of hinged seat 1, two traction beams 2, two corbel beams 3, two side beams 5 and partition walls 6, and these parts are all large-section hollow profiles. It provides a foundation for bearing the weight of the vehicle and transmitting the longitudinal force. A hinged support structure 4 is provided below the corbel 3, and the front and rear of the hinged support structure 4 are respectively connected to the hinged seat 1 and the partition wall 6, and the height transitions smoothly, avoiding excessive stress concentration. The hinged support structure 4 is welded by a middle floor 41 , a connecting floor 42 , a support vertical plate 43 and a support cover 44 , and is mainly used to support the hinged seat 1 . On the top of the "mesh"-shaped overall frame structure, a side floor 8 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com