Tire material, non-pneumatic tire with hollow cavity and preparation method of non-pneumatic tire

A non-pneumatic tire and tire technology, which is applied in the direction of non-pneumatic tires, special tires, tire parts, etc., can solve problems such as tire rupture, hidden dangers in tire driving, and wheel hub separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention will be described in detail below with reference to the drawings and specific embodiments.

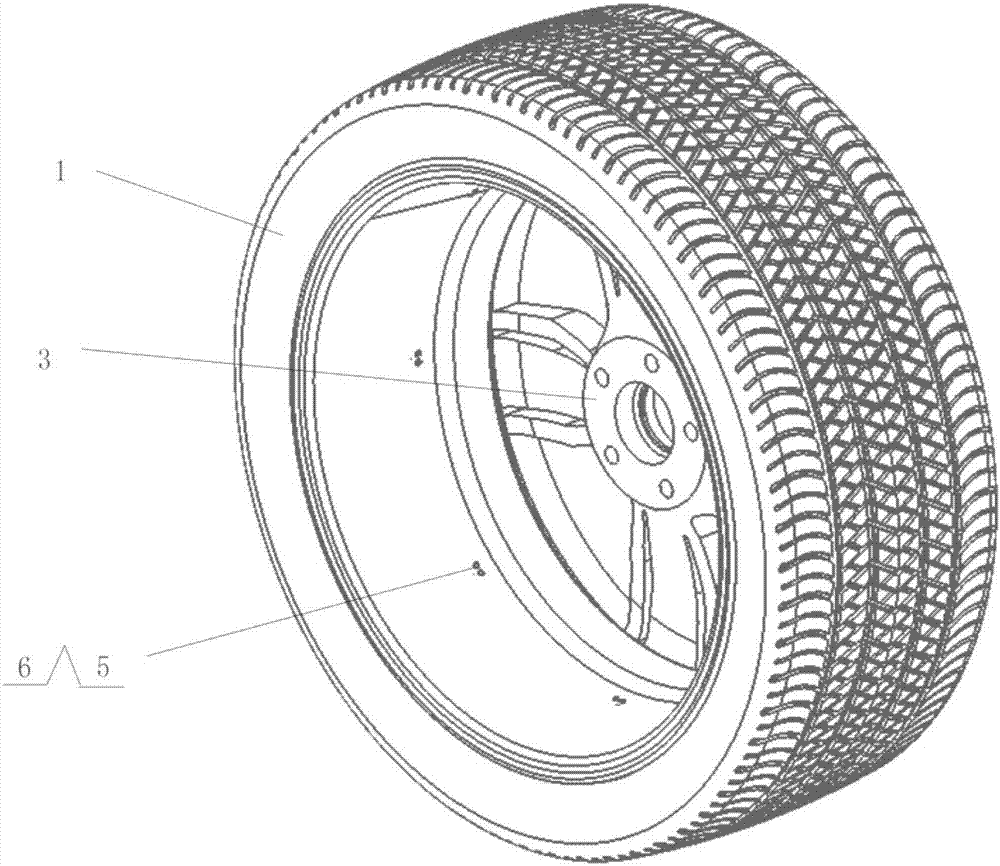

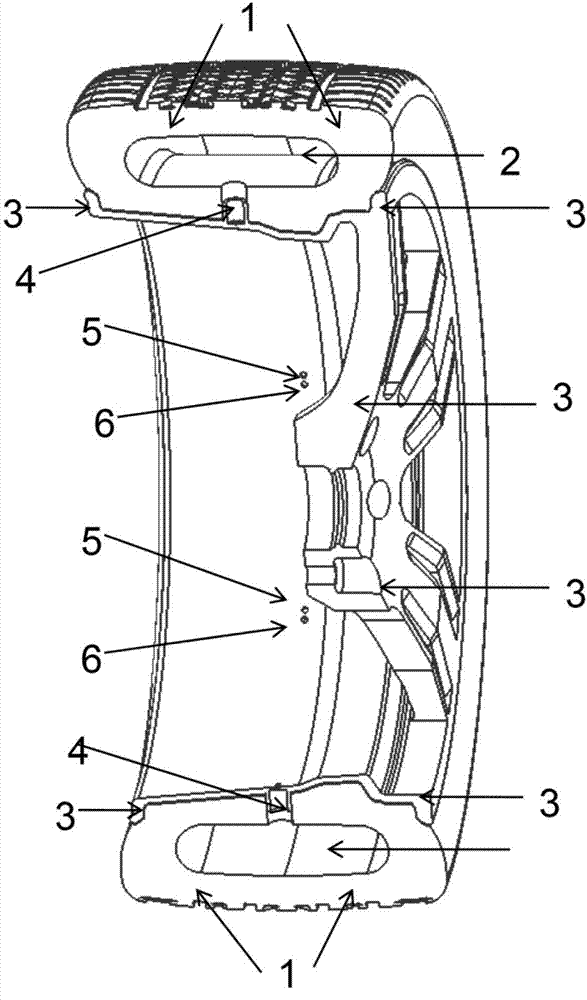

[0027] Reference Figure 1 to Figure 2 As shown, the present invention provides a pneumatic tire with a hollow cavity, including: a tire carcass 1 with a hollow cavity 2 and a wheel hub 3 wound around the tire carcass 1; the tire carcass 1 and the wheel hub 3 The hollow cavity 2 forms a closed annular structure with the tire carcass 1 through glue injection and fusion.

[0028] The cross section of the hollow cavity 2 is a prolate circular racetrack; the inner side of the tire carcass 1 is provided with several pairs of air outlet holes 6 and air suction holes 5 that penetrate the inner side of the hollow cavity 2.

[0029] The tire carcass 1 is made of polyurethane as a main material, and a curing agent, graphene, and white carbon black fiber are added as auxiliary materials. The preferred formulation composition is: polyurethane 70-94.5% wt., graphene 1-10% wt., white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com