Torsion spring long in service life

A torsion spring, long-life technology, applied in the direction of spring, spring/shock absorber, coil spring, etc., to achieve the effect of reducing deformation pressure, ensuring no attenuation, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The concept, specific structure and specific effects of the present invention will be clearly and completely described below in conjunction with the embodiments and drawings, so as to fully understand the purpose, characteristics and effects of the present invention. The various technical features created by the present invention can be combined interactively on the premise of not contradicting each other.

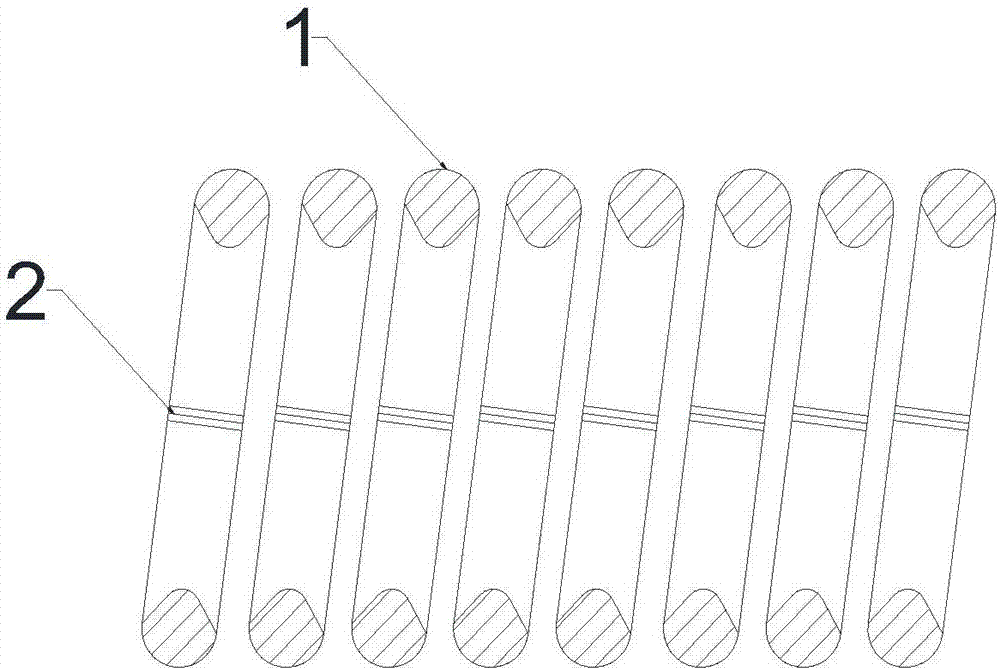

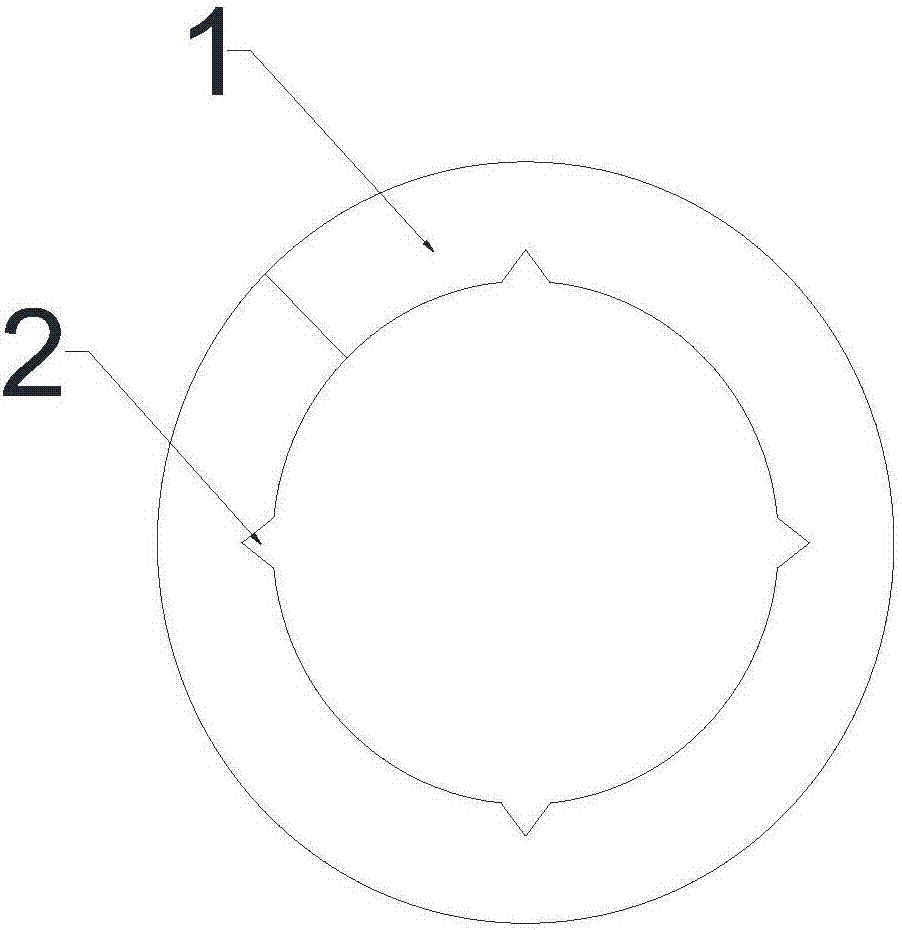

[0019] see Figure 1-2 , a long-life torsion spring, characterized in that it includes a spring body 1, the spring body 1 is made of spring steel, one side of the spring steel is cylindrical, and the other side is wedge-shaped. The unit deformation force of the wedge-shaped side of the spring steel is smaller than that of the cylindrical side, and the wedge-shaped side is set on the side with larger contraction deformation of the torsion spring to relieve denaturation pressure and effectively prevent fatigue deformation.

[0020] As a further improvement of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com