Constant-pressure self-moving temporary supporting hydraulic support for tunneling

A temporary support and hydraulic support technology, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of inability to stabilize the roadway roof, the influence of the smooth movement of the roadheader, and the increase in equipment maintenance. The effect of avoiding the crushing of the roof and surrounding rock, enhancing the adaptability of the support, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

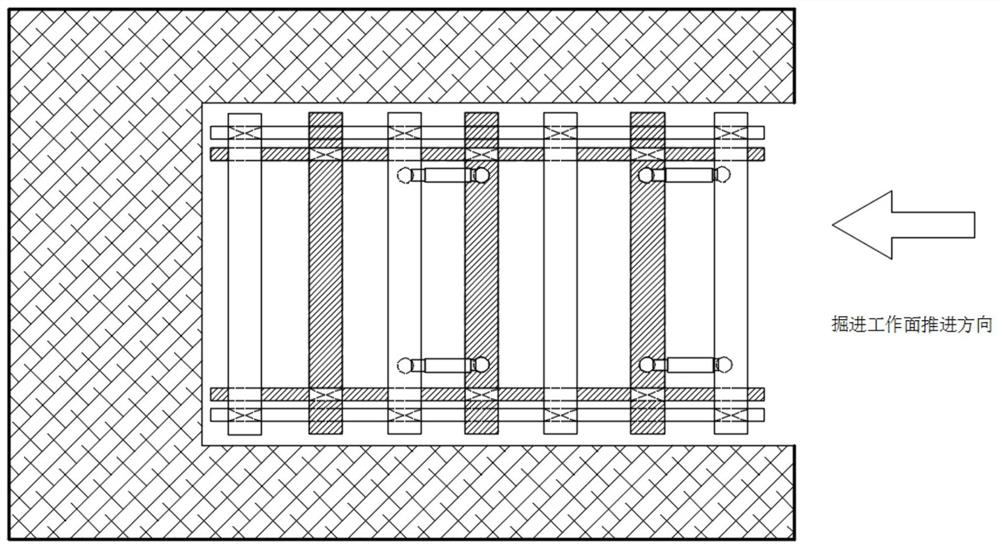

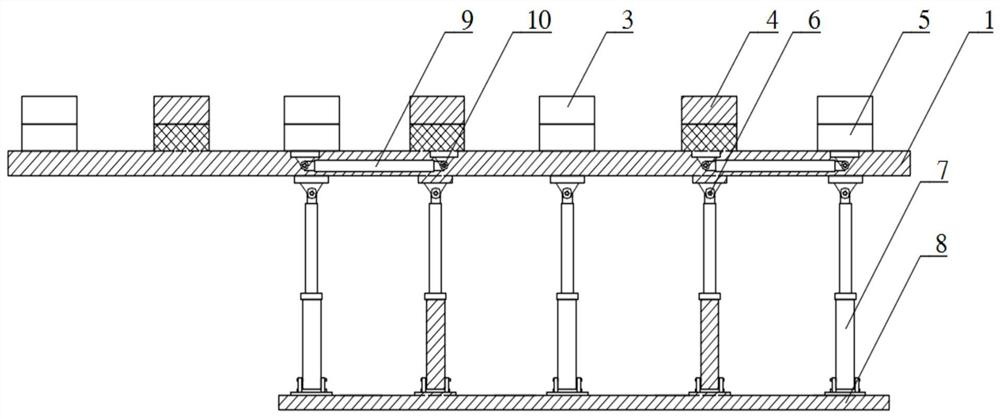

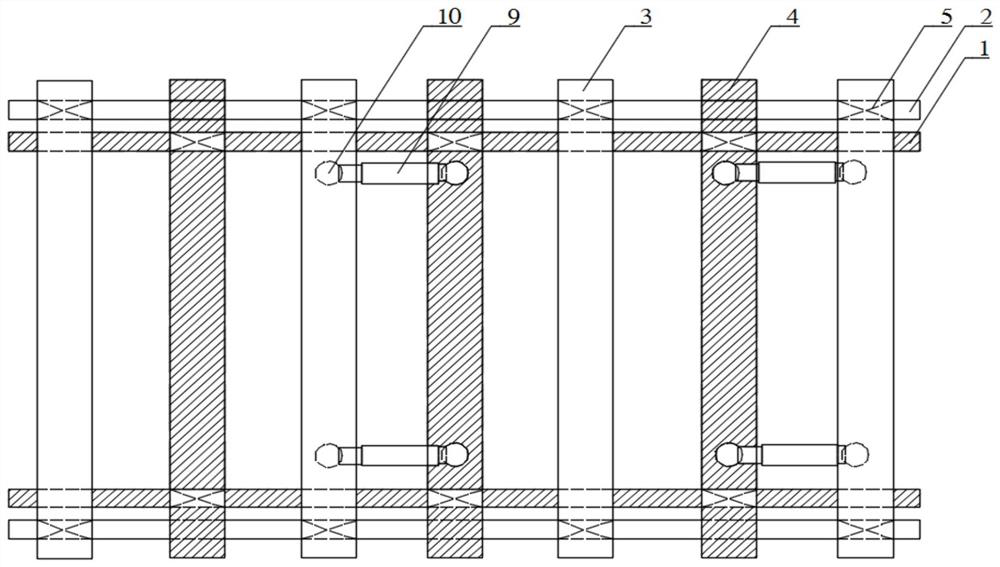

[0029] The invention provides a technical solution: a constant pressure self-moving temporary support hydraulic support for excavation, which consists of supporting inner beams 1, supporting outer beams 2, outer roof beams 3, inner roof beams 4, beam components 5, and hinged structures a6, hydraulic column 7, support bottom beam 8, push jack 9, hinged structure b 10 composition;

[0030] Two sets of support structures are set up for the temporary support hydraulic support, and the outer top beam 3 and the two supporting outer beams 2 are welded into a group of integral support structures through the beam assembly 5, and the inner top beam 4 and the two support inner beams are welded through the cross beam assembly 5. The beam 1 is welded into a group of integral support structures; the crossbeam assembly 5 is arranged below the two ends of the outer roof beam 3 and the inner roof beam 4, and is welded with the supporting outer beam 1 and the supporting inner beam 2 as a whole; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com