Three-step arch beam type support construction method for tunnel

A construction method and three-step technology, applied in the field of tunnel engineering, can solve problems such as long construction period, fast deformation rate of expansive soft rock, crushed and broken blocks of sprayed layer, etc., achieve early strength and crack resistance suppression, and prevent lateral Buckling instability and the effect of strengthening the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art fall within the protection scope of the present invention.

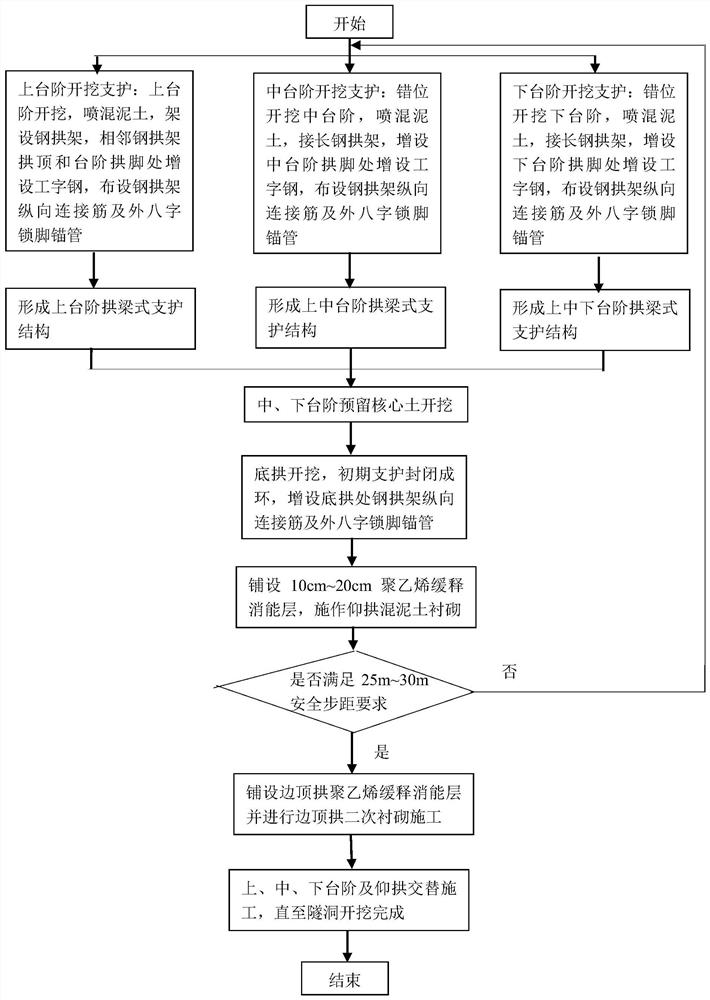

[0049] A construction method for a three-step arch beam type support in a tunnel according to an embodiment of the present invention specifically includes:

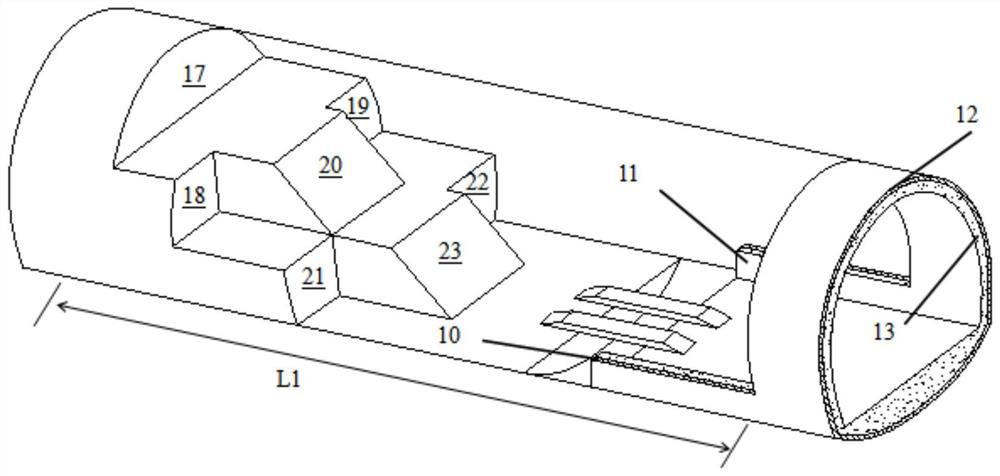

[0050] Step 1: First go up step 17 (see image 3 ) excavation, the excavation cycle footage is determined according to the distance between the steel arches, generally less than 1.0m, immediately after excavation, spray concrete to close the face, and initially spray 3cm ~ 5cm thick nano-silica fume synthetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com