Open caisson reinforcing method suitable for shield construction

A kind of caisson and shield technology, which is used in infrastructure engineering, earthwork drilling, soil protection and other directions, can solve problems such as bad social impact, soil disturbance, collapse, etc., to ensure safety, suppress settlement, and reduce deformation. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

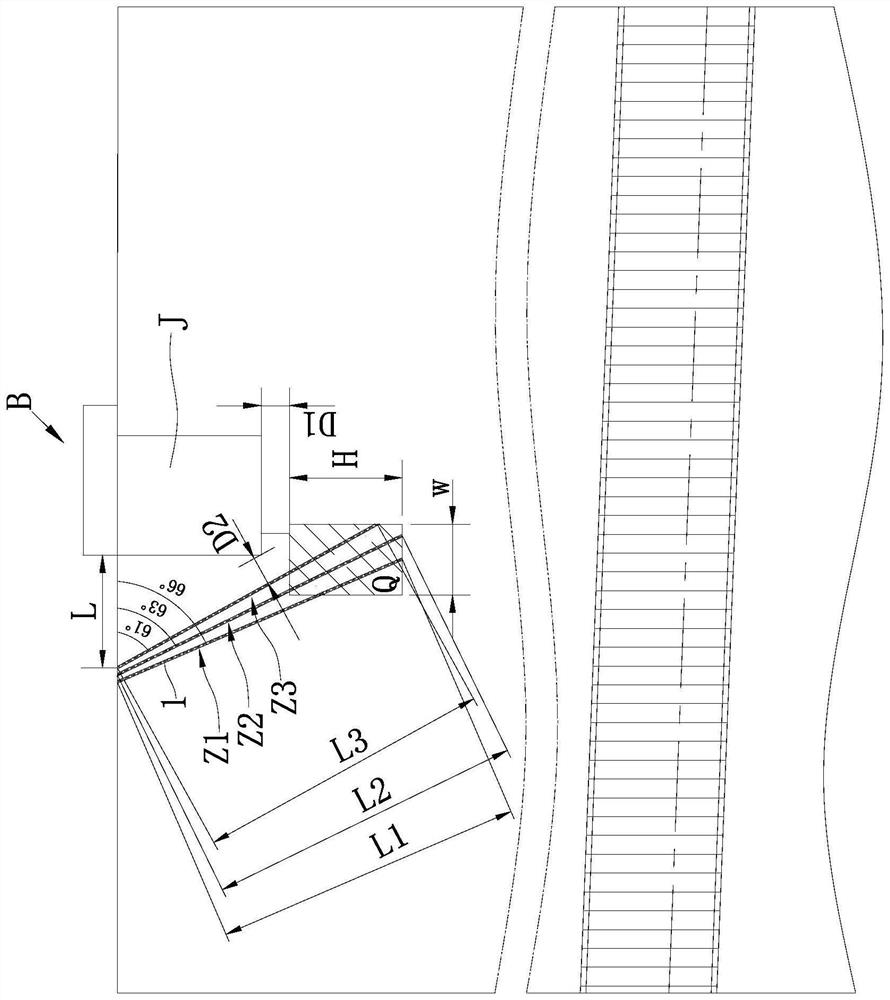

[0061] Such as figure 1 As shown, the reinforced pipe shed structure of this embodiment is used for the reinforcement treatment of the pump room B with a depth of about 10m. The specific reinforced pipe shed structure is obliquely inserted from the ground or the circumferential side of the caisson foundation to the bottom of the caisson J.

[0062] The reinforced pipe shed structure includes a plurality of grouting pipes 1, wherein the plurality of grouting pipes 1 are divided into three rows, and each row of grouting pipes 1 is distributed at intervals along the corresponding side of the caisson J, and constitutes the grouting pipes of each row 1 are arranged in parallel, and two adjacent rows of grouting pipes 1 are arranged apart from each other.

[0063] In this example, the gaps are distributed between every two adjacent rows of grouting pipes 1 , and the vertical distances between the tube cores of every adjacent row of grouting pipes 1 are equal. It is convenient for ...

Embodiment 2

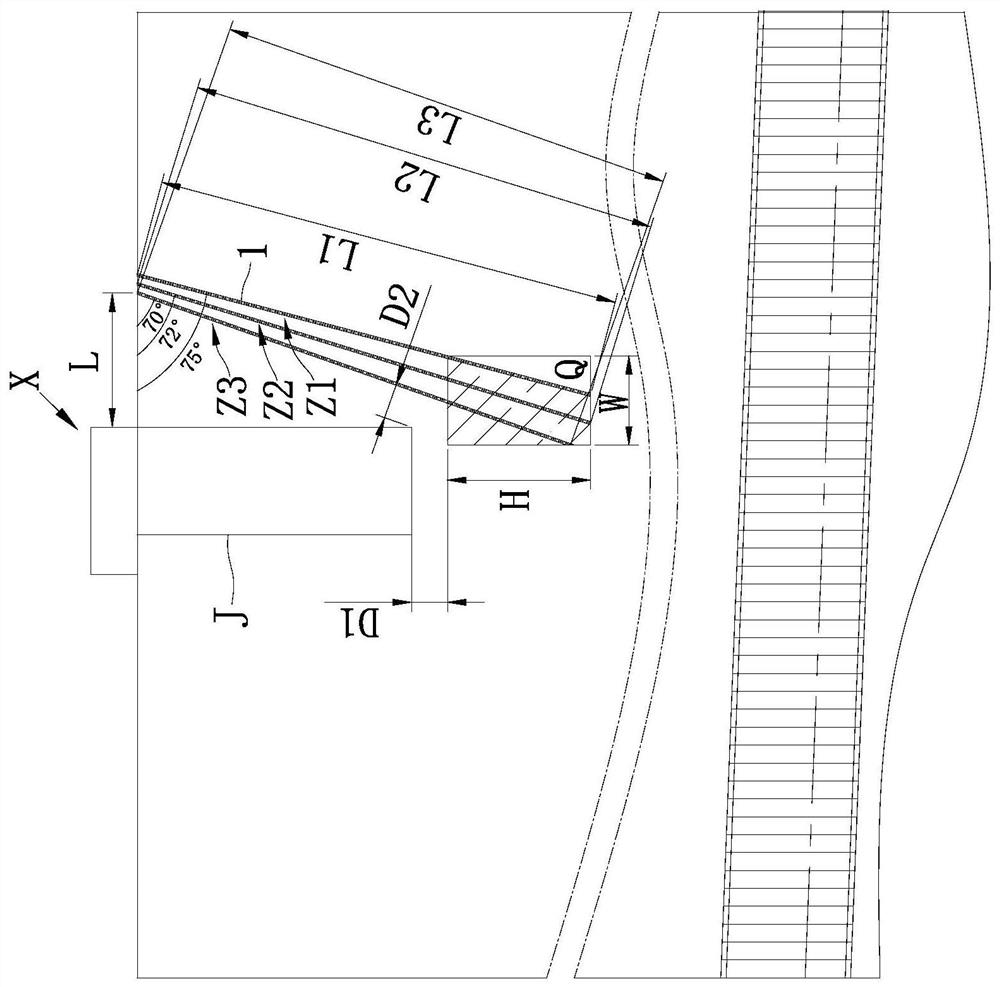

[0114] Such as figure 2 As shown, the reinforced pipe shed structure of this embodiment is used for the reinforcement treatment of the water absorption well X with a depth of 15m.

[0115] Specifically, the reinforced pipe shed structure adopted is basically the same as the reinforced pipe shed structure in Implementation 1, with the difference.

[0116] L1=26.2m, L2=26.5m, L3=25.6m.

[0117] The angle formed by the first grouting pipe row Z1 and the ground is 75°, the angle formed by the second grouting pipe row Z2 and the ground is 72°, and the angle formed by the third grouting pipe row Z3 and the ground is 70°.

[0118] The depth of the reinforcement zone Q is H, the vertical distance from the grouting inlet end of the third grouting pipe row Z3 to the caisson J is L, H=8m, L=7.5m.

[0119] In addition, there are also differences in the implementation, that is, in the depth of the drilled hole to meet the lower pipe of the steel pipe and the sleeve valve pipe.

[0120] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com