Packaging device for shoemaking

A technology for shoes and shoe stretchers, which is applied in the direction of shoemaking machinery, footwear, and soles, etc. It can solve the problem of increasing the looseness of the fit gap of the soles, constricting the cumbersome product quality of the soles, and pushing the colloidal clots out of the way. Needle angular distance and other issues, to achieve the effect of saving visual correction operations, ensuring the curvature of the elastic adjustment area, and improving the effect of fine-tuning the fitting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

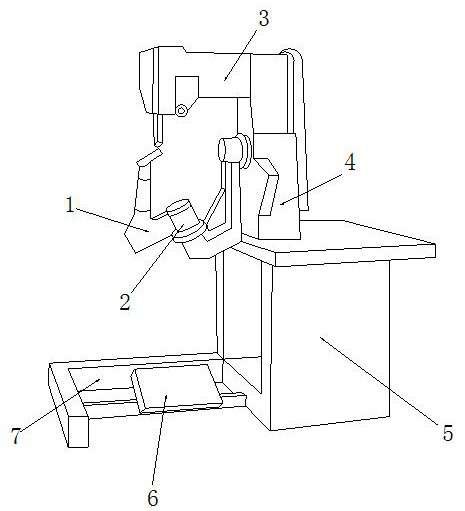

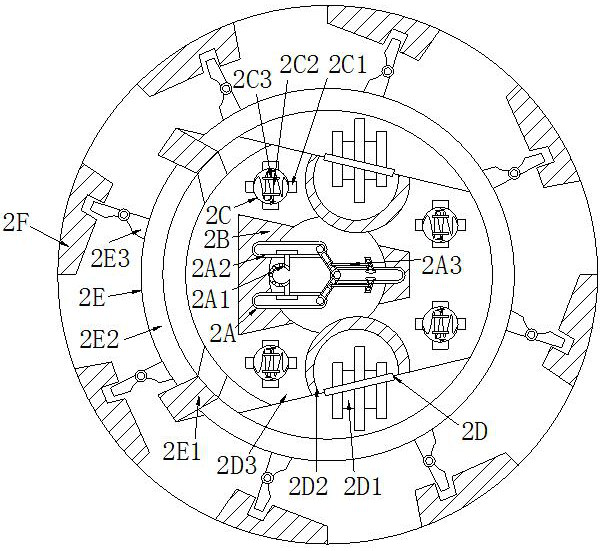

[0033] see Figure 1-Figure 6, the present invention provides a packaging device for shoemaking, the structure of which includes: a shoe support rod seat 1, a bevel angle distance bracket 2, a sewing machine arm 3, a gear transmission box 4, a machine support seat 5, and a roller pedal 6 , the base frame 7, the inclined-plane angular distance platform 2 is nested in the lower right corner of the shoe support rod seat 1 and is on the same vertical plane, and the described inclined-plane angular distance platform 2 is installed on the left side of the gear transmission box 4 On the side, the sewing machine arm 3 is mechanically connected with the gear transmission box 4 and is on the same vertical plane. The gear transmission box 4 is inserted in the upper left corner of the machine support base 5 and is perpendicular to each other. The shaft is mechanically connected to the base frame 7 and is on the same level. The base frame 7 is welded to the lower left corner of the machine...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a packaging device for shoemaking, other aspects are the same as in Embodiment 1, the difference is that:

[0041] see figure 2 , the pick plate folded ring 2E is composed of a folded frame plate 2E1, an inner frame ring 2E2, and a pointer pick 2E3, the folded frame plate 2E1 is movably connected with the inner frame ring 2E2, and the pointer pick 2E3 is provided with two The above and around the center of the inner frame ring 2E2 are inserted together, through the detection of the side curvature of the folding frame plate 2E1 and the fine adjustment of the angular distance scale of the pointer paddle 2E3, the correction and stable operation of the overall angular distance and slope curvature value are formed.

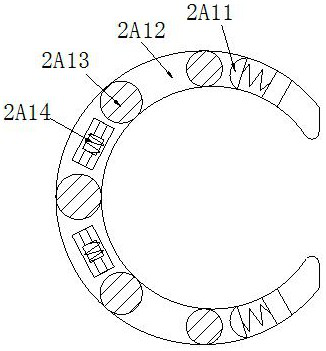

[0042] see Figure 6 The folding frame plate 2E1 is composed of a rack piece 2E11, a three-section folding plate 2E12, a supporting slide bar 2E13, and an arc buckle bending plate 2E14. On the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com