Integrated firecracker

An integrated, firecracker technology, applied to firecrackers and other directions, can solve the problems of low reuse rate and low safety factor of firecrackers, and achieve the effects of simple structure, reduced production cost, and simplified production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

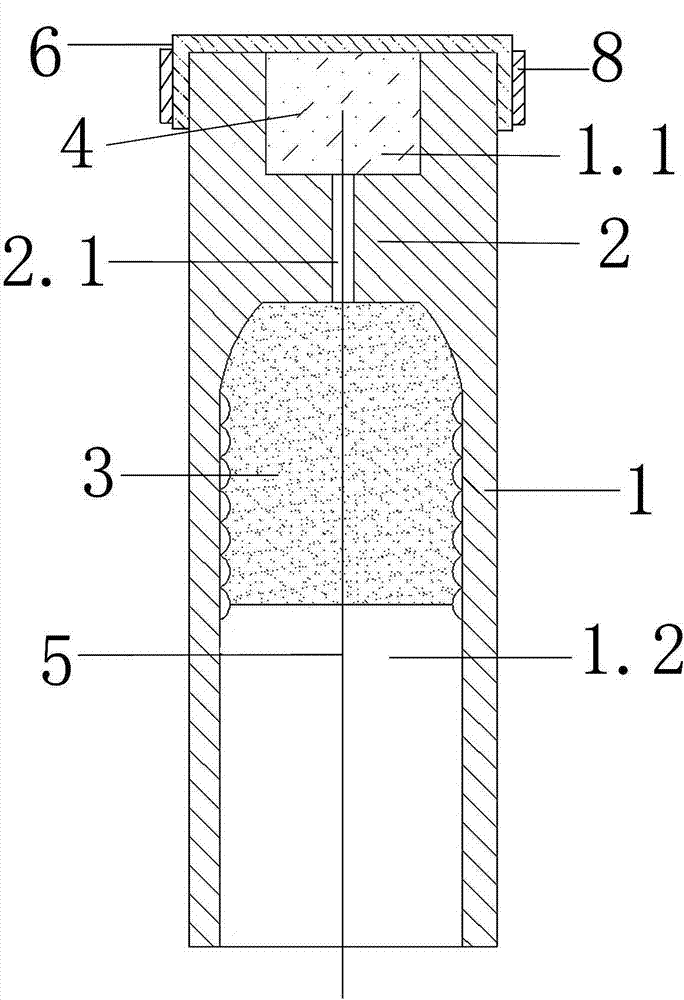

[0019] Embodiment 1: a kind of integrated firecracker monomer, such as figure 1 As shown, including the cylinder body 1 and the lead wire 5, the cylinder body 1 made of tough plastic has a partition 2 integrated with it. The partition 2 divides the interior of the cylinder body 1 into two upper and lower cavities, and the upper cavity 1.1 is filled with drugs. 4. The lower cavity has a fixed lead structure; the partition 2 is provided with a lead hole 2.1, and the lead wire 5 is led out of the cylinder 1 through the lead hole 2.1 and the fixed lead structure. The upper cavity 1.1 is provided with a sealing layer 6 at the end. The anchoring structure is the anchoring filler 3 filled in the lower cavity. The inner wall of the lower cavity 1.2 has protrusions. The end of the upper cavity 1.1 is provided with a cap 8 for tightening the sealing layer. The length of the cylinder is 30-40mm, the upper cavity accounts for 1 / 8-1 / 6 of the length of the cylinder, and the partition acco...

Embodiment 2

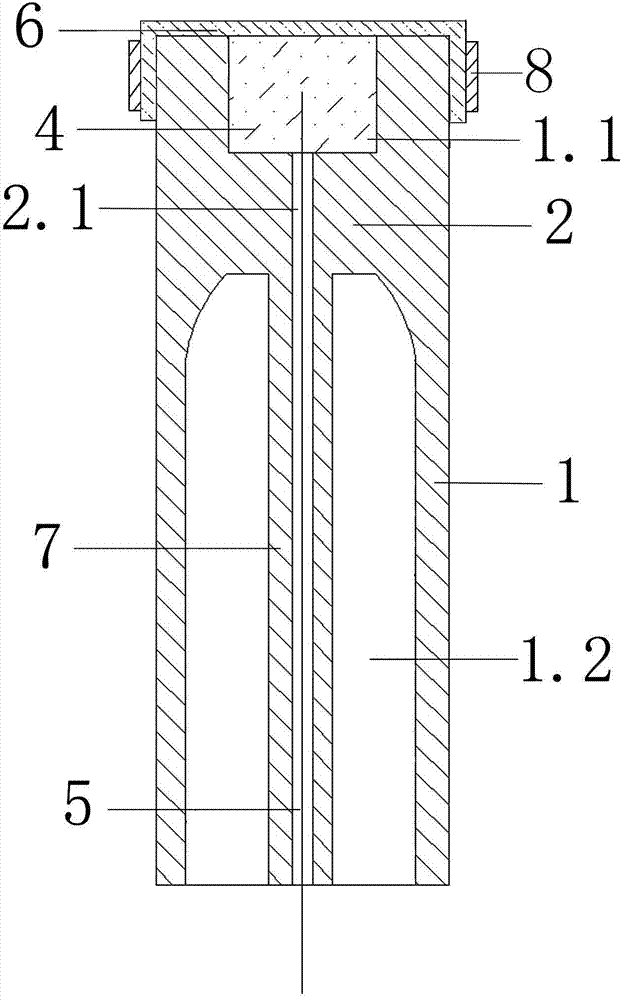

[0028] Embodiment 2: a kind of integrated firecracker monomer, such as figure 2 As shown, including the cylinder body 1 and the lead wire 5, the cylinder body 1 made of tough plastic has a partition 2 integrated with it. The partition 2 divides the interior of the cylinder body 1 into two upper and lower cavities, and the upper cavity 1.1 is filled with drugs. 4. The lower cavity has a fixed lead structure; the partition 2 is provided with a lead hole 2.1, and the lead wire 5 is led out of the cylinder 1 through the lead hole 2.1 and the fixed lead structure. The upper cavity 1.1 is provided with a sealing layer 6 at the end.

[0029] The fixing structure is a lead post 7 arranged in the lower cavity 1.2, the lead post 7 is a cylinder structure, one end forms an integral structure with the partition 2, and the end of the other end is flush with the end of the cylinder 1, The inner hole of the lead post 7 is equal in diameter to and corresponds to the lead hole 2.1. The end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com