Bolt pre-tension torque ultrasonic guided-wave monitoring method based on improved time reversal method

A technology of bolt pre-tightening force and time reversal, applied in force/torque/work measuring instruments, measuring torque/torsion force during tightening, measuring devices, etc., can solve problems such as difficult to compare signal phase changes, and improve detection accuracy , the effect of large monitoring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

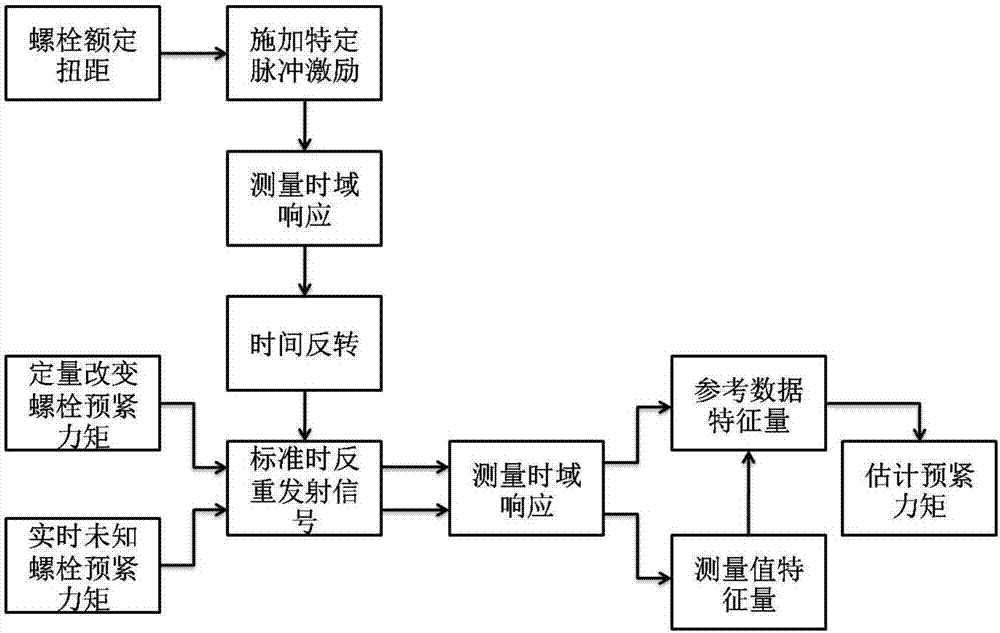

[0035] Such as figure 2 As shown, the method consists of two parts:

[0036] Step 1: Create a reference database offline:

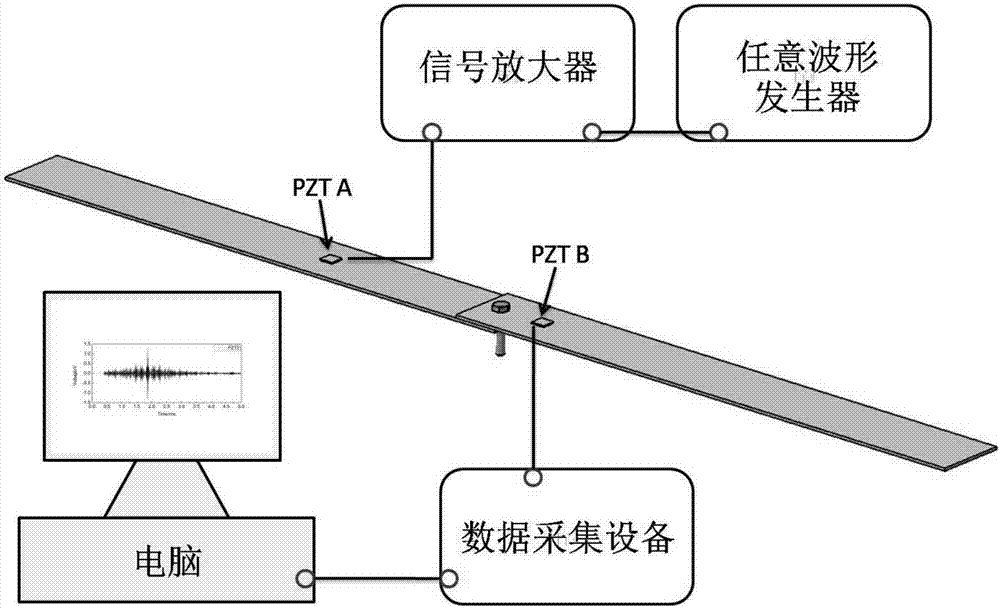

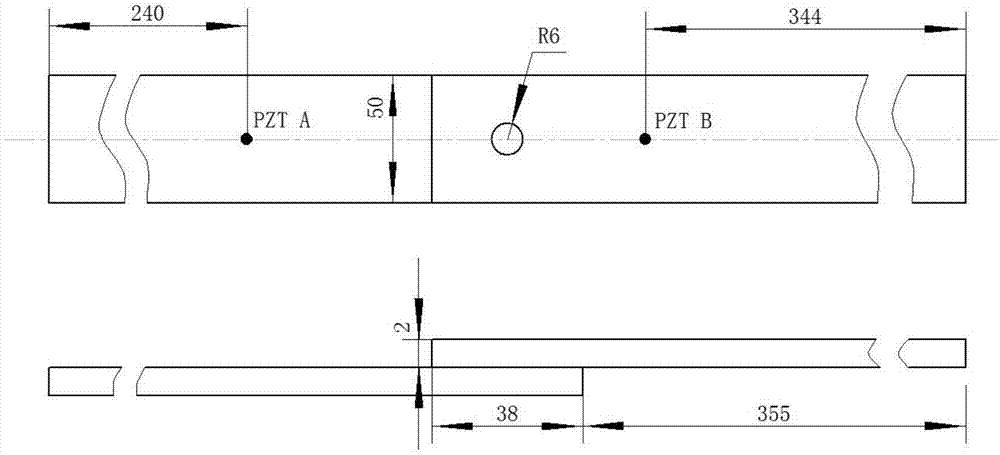

[0037] Step 1.1: Use 3MDP460 industrial adhesive to paste two pieces of PZT components on the connection structure, which are respectively used as actuators and sensors. See the location image 3; The size of PZT is 10mm×8mm×1mm, the model is P5H, and the manufacturer is Baoding Hongsheng Acoustic Electronic Equipment Co., Ltd. The two PZT elements are located on both sides of the bolt to be tested, respectively, 134mm and 30mm away from the center of the bolt, and the principal deformation directions of the center of the bolt and the two PZT elements are collinear. The 3MDP460 industrial adhesive layer is thin and uniform, the thickness of the adhesive layer is 0.04-0.06mm, and it is cured at a temperature of 50°C to 60°C for two hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com