Waste iron pulverizer

A pulverizer and pulverizing mechanism technology, applied in the industrial field, can solve the problems of substandard iron, insufficient pulverization, lack of secondary pulverizing devices, etc., and achieve the effect of reducing the scrap rate and improving the pulverization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

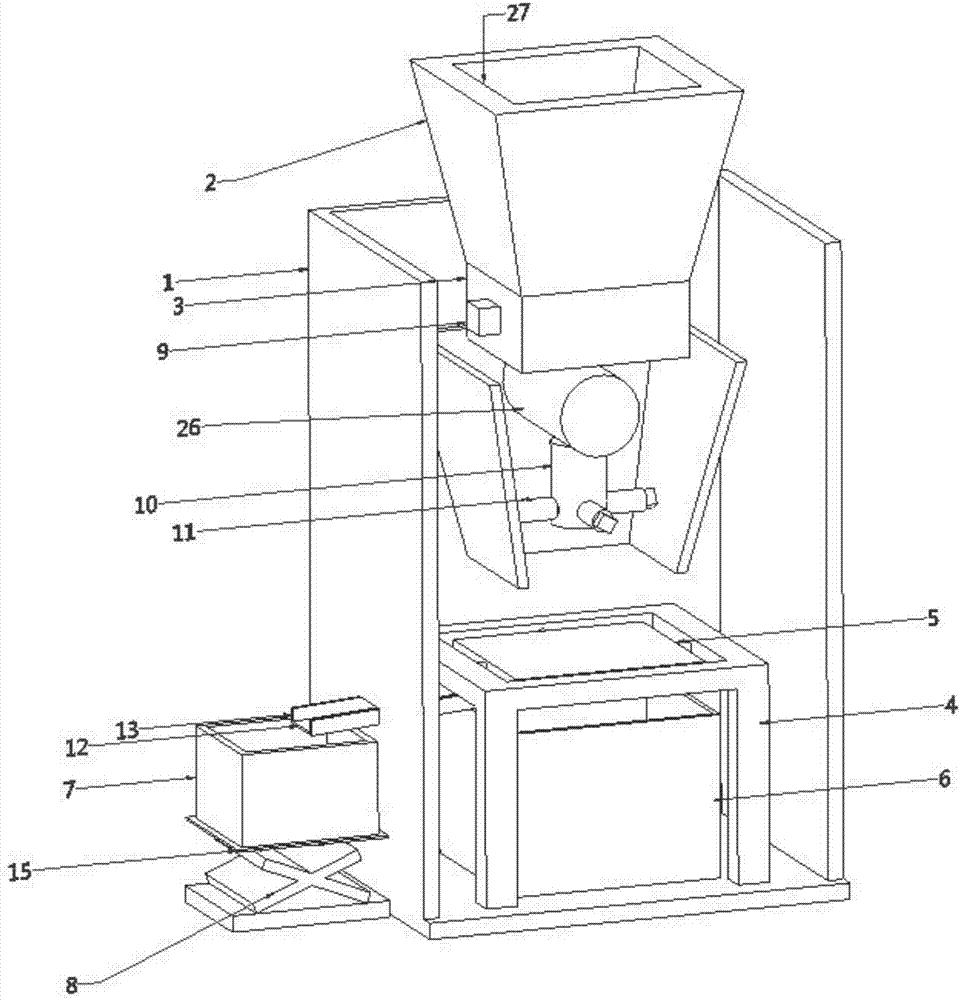

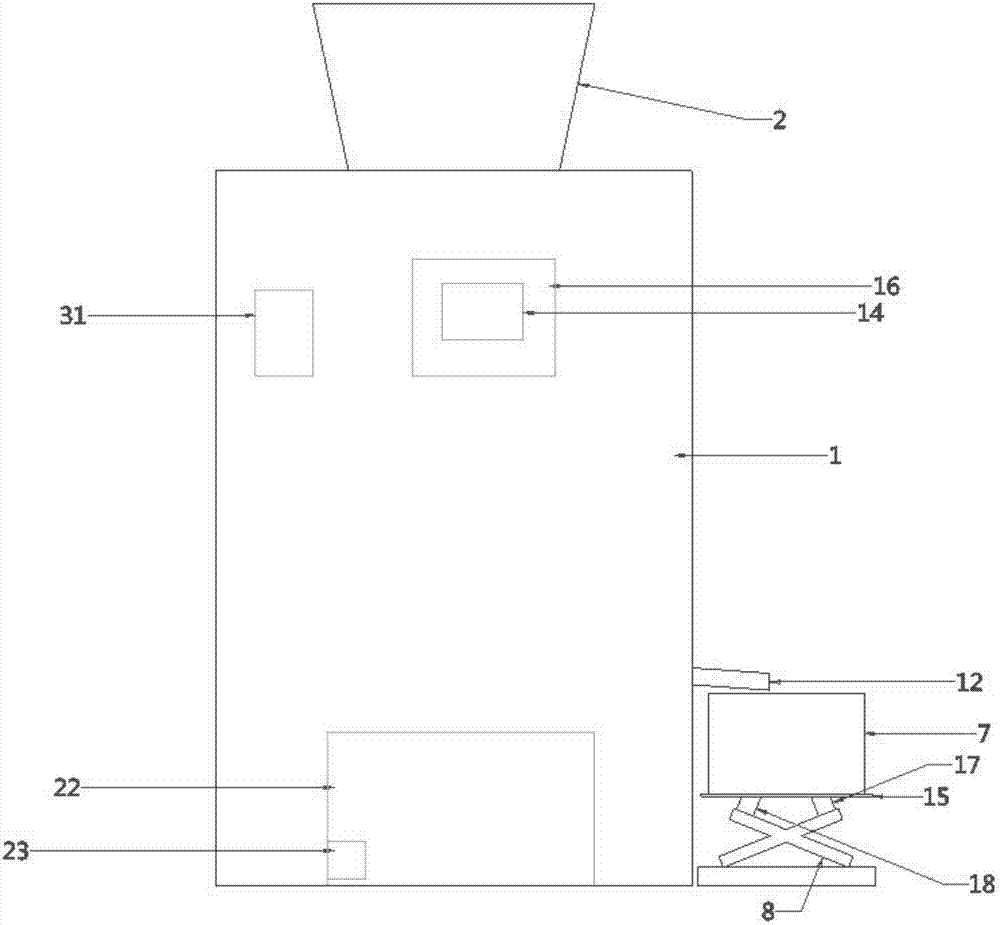

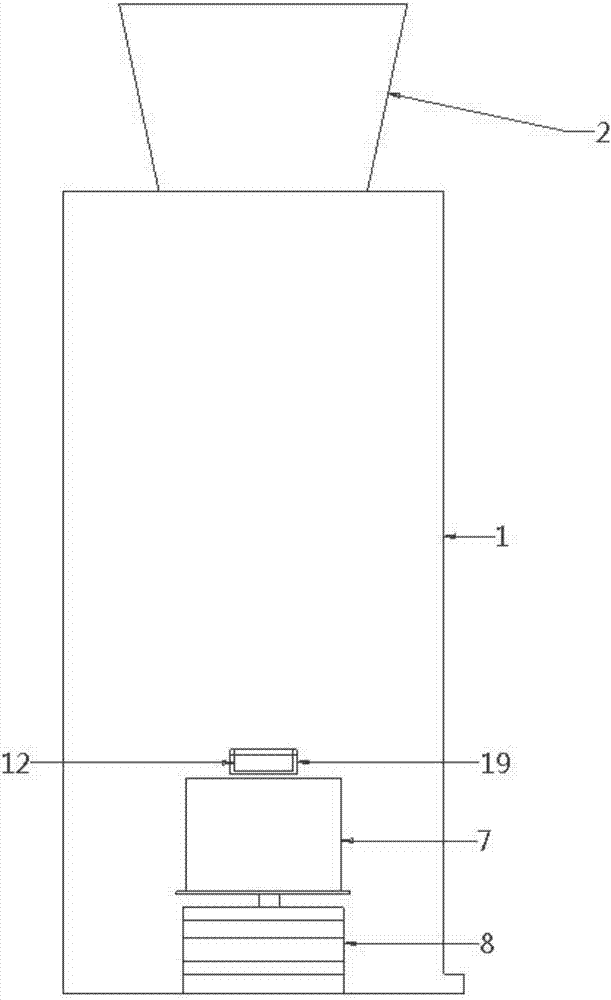

[0021] The present invention will be described in detail below with reference to the drawings, such as Figure 1-6 A scrap iron crusher is shown, comprising a body (1), a feeding hopper (2) is installed at the upper end of the body (1), and a feeding pipe (3) is installed at the lower end of the feeding hopper (2), so A crushing mechanism is installed at the lower end of the feeding pipe (3), a screen bracket (4) is placed on the inner bottom surface of the body (1), and a vibration motor (24) is installed on the right side of the bracket (4). The inside of the screen support (4) is equipped with a screen (5), the inside of the support (4) and the outside of the screen (5) are connected by a spring structure, and a plc placement slot (14) is opened on the back of the body (1) ), a plc controller (16) is placed in the plc placement slot (14), a square hole (20) is opened on the right side of the fuselage (1), and the square hole (20) is placed in the storage box (6) A groove (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com