Segmented Conveyor System for Polishing Machines

A transmission system and polishing machine technology, applied in grinding/polishing equipment, matching and sorting, computer parts, etc., can solve the problems of ineffective saving of power resources, impractical equipment, etc., to increase practicability and stability , increase the effect, avoid the offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

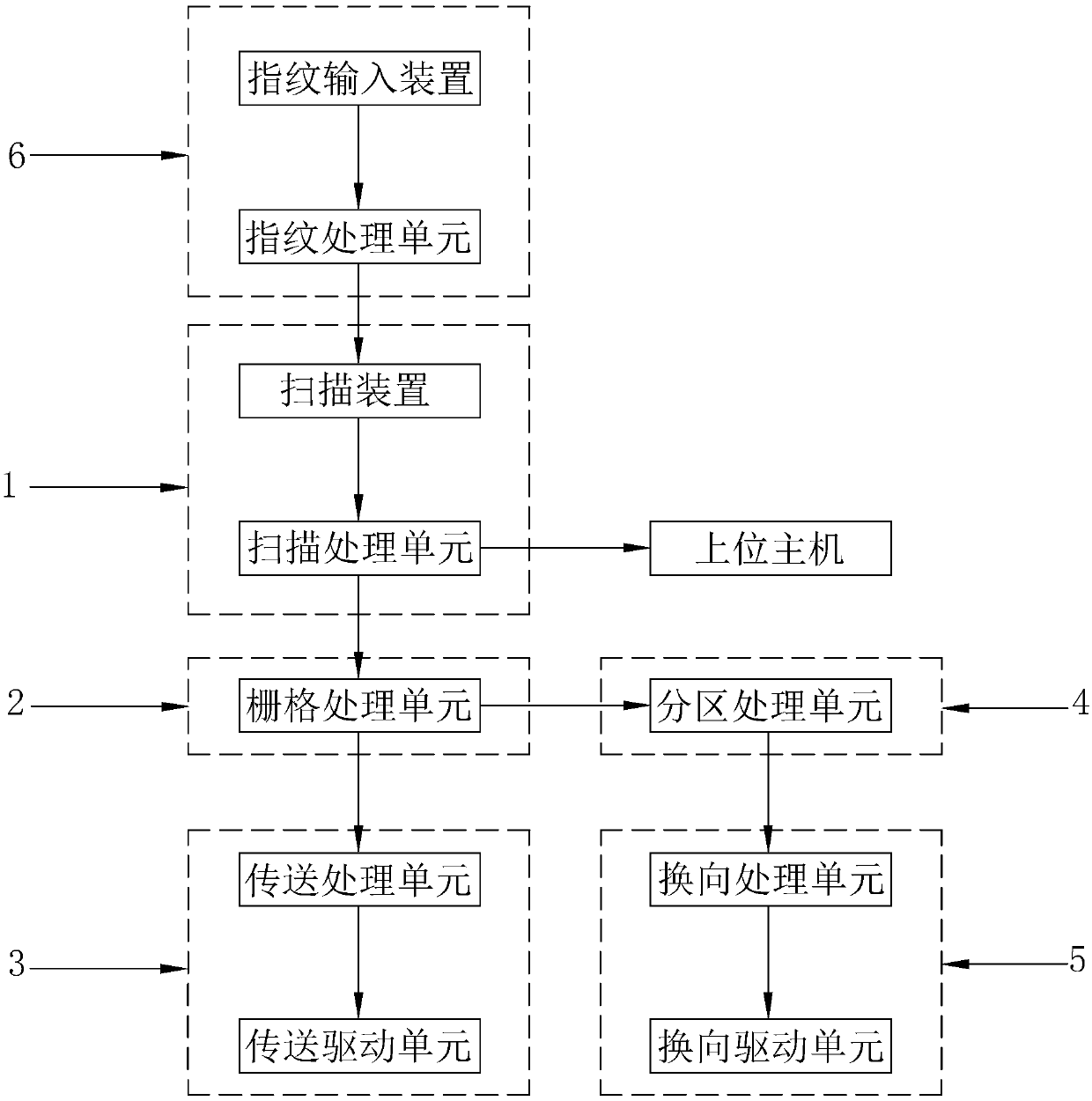

[0025] Embodiment: a kind of segmental conveying system for polishing machine, such as figure 1 As shown, it includes a scanning subsystem 1 , a grid subsystem 2 , a segmentation control device 3 , a partition subsystem 4 , a reversing subsystem 5 and a fingerprint verification subsystem 6 .

[0026] There are 6 rows and 6 rows of transmission rollers on the transmission table, and a transmission roller bracket is arranged on the lower side of the transmission rollers. The direction of the rotation axis of the transmission rollers is arranged along the horizontal direction. The direction is set along the vertical direction, and the scanning subsystem 1 is set on the transfer platform. The scanning subsystem 1 includes a scanning device, a scanning processing unit, and a host computer. The scanning device includes an image acquisition device, which collects the scanned Multiple images of the plate and the drive roller; after the acquisition is completed, the image information i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com