A night vision compatible near-infrared absorption anti-glare optical film and its preparation method and application

A technology compatible with near-infrared absorbers and night vision, applied in radiation-absorbing coatings, coatings, devices for coating liquids on surfaces, etc. Low pass rate and other issues, to achieve good visibility, excellent visible light anti-glare performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

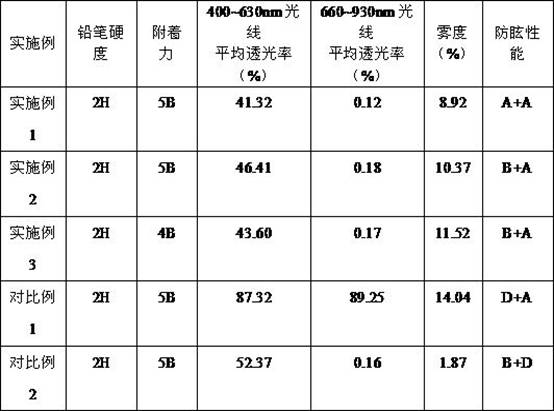

Embodiment 1

[0035]Preparation of near-infrared absorption anti-glare coating solution: add 2.8 parts by weight of near-infrared absorbers (0.4 parts by weight of N660, 0.6 parts by weight of N750, 0.6 parts by weight of N800 and 1.2 parts by weight of N890, German infrared absorption products) to 50 parts by weight of mixed Thinner (commercially available dichloromethane: methyl ethyl ketone = 1:1), stirred until completely dissolved; sequentially add 60 parts by weight of hydroxyacrylate resin (SEN-1250, Korea Juming Chemical), 6 parts by weight of resin curing agent (N75 , Germany Bayer Company), 5 parts by weight of monodisperse polymethyl methacrylate particles with an average particle size of 3 μm (MX300, Soken Chemical) and 1 part by weight of leveling agent (BYK-361, BYK Company), stirring and mixing evenly , to prepare a near-infrared absorbing anti-glare coating solution.

[0036] Preparation of near-infrared-absorbing anti-glare optical film: In a thousand-class clean environmen...

Embodiment 2

[0039] Preparation of near-infrared absorption anti-glare coating solution: add 2.2 parts by weight of near-infrared absorbers (0.4 parts by weight of N660, 0.4 parts by weight of N750, 0.6 parts by weight of N800 and 0.8 parts by weight of N890, German infrared absorption products) to 45 parts by weight of mixed Thinner (commercially available dichloromethane: ethyl ketone = 1:1), stirred until completely dissolved; sequentially add 50 parts by weight of aliphatic epoxy resin (EHPE3150, Daicel, Japan), 4 parts by weight of resin curing agent (polyetheramine EC301, BASF, Germany), 3 parts by weight of monodisperse polystyrene particles with an average particle size of 6 μm (SBX-6, Sekisui Chemical Co.), 0.5 parts by weight of leveling agent ((EFKA-3883, Dutch Efka Company) and 1 part by weight of a dispersant (Kerper-630, Kerper Company, USA), and stirred evenly to prepare a near-infrared absorbing anti-glare coating liquid.

[0040] Preparation of near-infrared absorbing anti...

Embodiment 3

[0043] Preparation of near-infrared absorbing anti-glare coating solution: add 2.6 parts by weight of near-infrared absorbers (0.6 parts by weight of N660, 0.4 parts by weight of N750, 0.6 parts by weight of N800 and 1.0 parts by weight of N890, German infrared absorption products) to 40 parts by weight of mixed Thinner (commercially available dichloromethane: methyl ethyl ketone = 1:1), stirred until completely dissolved; sequentially add 55 parts by weight of hydroxyacrylate resin (TAB-700, Japan DIC), 5 parts by weight of resin curing agent (N3390, Germany Bayer), 6 parts by weight of monodisperse polymethyl methacrylate particles with an average particle size of 5 μm (MX500, Soken Chemical Co.), 1 part by weight of leveling agent ((EFKA-3883, Dutch Efka Company) and 1 Parts by weight of a dispersant (Kerper-630, Kerper Corporation, USA), stirred and mixed evenly to prepare a near-infrared absorbing anti-glare coating liquid.

[0044] Preparation of near-infrared absorbing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com