A kind of near-infrared absorption filter film and preparation method thereof

A near-infrared absorber and filter film technology, which is applied in chemical instruments and methods, pressure-sensitive films/sheets, film/sheet-shaped adhesives, etc., can solve problems such as difficult removal and cumbersome installation process, and achieve easy to install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

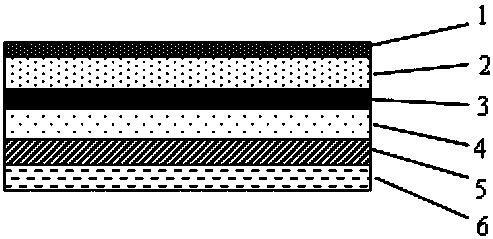

Image

Examples

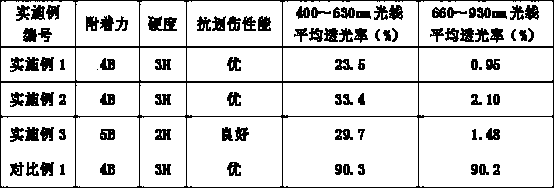

Embodiment 1

[0046] Scratch-resistant coating solution preparation: Add 15 parts by weight of dipentaerythritol hexaacrylate (DPHA, Sartomer, USA) and 20 parts by weight of mixed diluent to 60 parts by weight of polyurethane acrylate (Sartomer, CN9006) resin (commercially available, toluene: propylene glycol methyl ether = 1:1), stir and mix evenly; add 5 parts by weight of a photoinitiator (Swiss Ciba, Irgacure 184) to the mixture, and stir evenly.

[0047] Composite adhesive layer coating solution preparation: 0.9 parts by weight of near-infrared absorber (0.3 parts by weight of EPOLIGHT TM 6661, absorption peak λ max =669nm, 0.3 parts by weight EPOLIGHT TM 4037, absorption peak λ max =743nm, 0.3 parts by weight EPOLIGHT TM 5587, absorption peak λ max =815nm, American Eprene Company) and 1.5 parts by weight of dispersant (Kerper, Kerper-602 in the United States) were added to 20.6 parts by weight of mixed diluent (commercially available dichloromethane: ethyl ketone = 1:1), stirred a...

Embodiment 2

[0054] Scratch-resistant layer coating solution preparation: to 50 parts by weight of polyurethane acrylate (Nippon Synthetic Chemical Company, brand 1700) resin, add 20 parts by weight of dipentaerythritol hexaacrylate (Sartomer, DPHA, USA) and 25 parts by weight of mixed Diluent (commercially available, toluene: propylene glycol methyl ether = 1:1), stirred and mixed uniformly; 5 parts by weight of photoinitiator (Swiss Ciba, Irgacure 184) was added to the mixed solution, and stirred evenly.

[0055] Composite adhesive layer coating solution preparation: 1 weight part of near-infrared absorber (0.5 weight part of EPOLIGHT TM 6661, absorption peak λ max =669nm, 0.5 parts by weight EPOLIGHT TM 3036, absorption peak λ max =773nm, American Eprene Company) and 1 weight part of dispersant (American Kerper, Kerper-602) were added to 20 weight parts of mixed diluent (commercially available dichloromethane: ethyl ketone = 1:1), stirred and mixed evenly; Add 70 parts by weight of...

Embodiment 3

[0062] Scratch-resistant coating solution preparation: Add 15 parts by weight of dipentaerythritol hexaacrylate (DPHA, Sartomer, USA) and 20 parts by weight of mixed diluent to 60 parts by weight of polyurethane acrylate (Sartomer, CN9006) resin (commercially available, toluene: propylene glycol methyl ether = 1:1), stir and mix evenly; add 5 parts by weight of a photoinitiator (Swiss Ciba, Irgacure 184) to the mixture, and stir evenly.

[0063] Composite glue layer coating liquid preparation: 0.5 weight part near-infrared absorber (0.25 weight part IR650, absorption peak λ max =798nm, 0.25 parts by weight IR852, absorption peak λ max =852nm Changchun Rainbow Technology Co., Ltd.) and 1 part by weight of dispersant (Kerper, Kerper-602 in the United States) were added to 21.5 parts by weight of mixed diluent (commercially available dichloromethane: methyl ethyl ketone = 1:1), stirred and mixed evenly; Add 70 parts by weight of polyurethane composite adhesive (Sanwo Aerospace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com