A Micro-arc Oxidation Electrolyte System Added Calcium Lactate

A technology of micro-arc oxidation and magnesium alloy, which is applied in the direction of electrolytic coating, anodic oxidation, surface reaction electrolytic coating, etc., can solve the problems of inability to maintain support function and hinder wound healing, etc., and achieve good biological performance and biocompatibility Good, good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

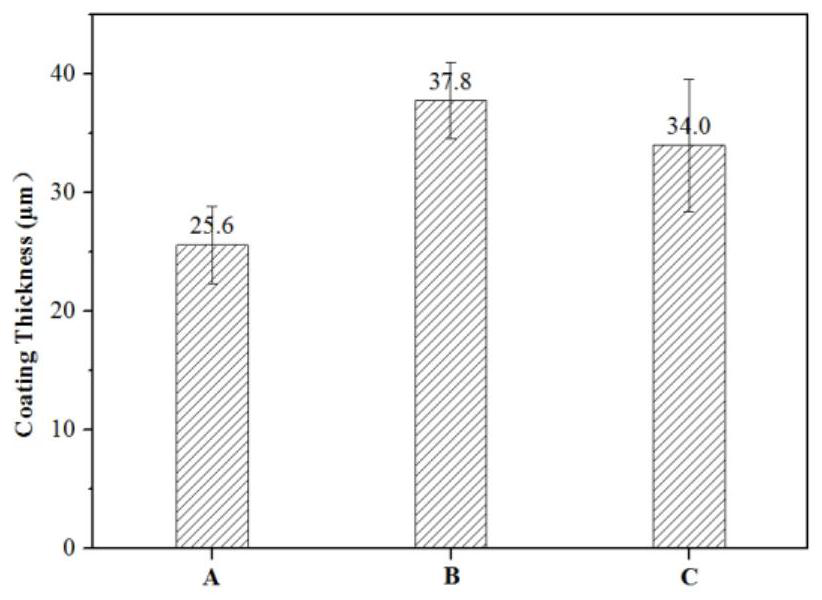

[0046] The micro-arc oxidation film layer prepared in this example involves three electrolyte systems containing different calcium sources, including calcium gluconate, which has been studied more, and calcium lactate, calcium carbonate, etc., which have been less studied. The calcium contents of the above three calcium sources are 9%, 13% and 40% respectively. The calcium content in the organic calcium sources calcium gluconate and calcium lactate is significantly lower than that in the inorganic calcium source calcium carbonate. This experiment systematically compared and studied the properties of the micro-arc oxidation coatings prepared under the above three different calcium source electrolyte systems, and showed the differences between the micro-arc oxidation coatings prepared by organic calcium and inorganic calcium.

[0047] 2. Experimental materials and methods

[0048] 2.1 Substrate and film preparation

[0049] The substrate used in the experiment is a self-cast M...

Embodiment 2

[0096] 1. The micro-arc oxidation film layer prepared in this experiment involves three different electrolyte systems, namely: calcium lactate as the calcium source, and the calcium-phosphorus molar ratio is set to 1:3, 1:4 and 1:5 , and are defined as B3, B4, and B5, respectively. The calcium source used in the micro-arc oxidation experiment was calcium lactate Ca(C 3 h 5 o 3 ) 2 ﹒ 5H 2 O, the molar concentration of calcium ions is 0.006mol / L, and the mass concentration is 1.848g / L; the phosphorus source used in the experiment is (NaPO 3 ) 6 , the concentrations are 1.836g / L, 2.448g / L and 3.060g / L respectively; the remaining electrolyte components and concentrations are KOH, 5g / L; NH 4 HF 2 ,7g / L; C 3 h 8 o 3 and N(CH2 CH 2 Oh) 3 Concentration is 5ml / L; H 2 o 2 The concentration is 7ml / L. The experimental materials and methods are the same as those described in Example 1.

[0097] 2. Experimental results

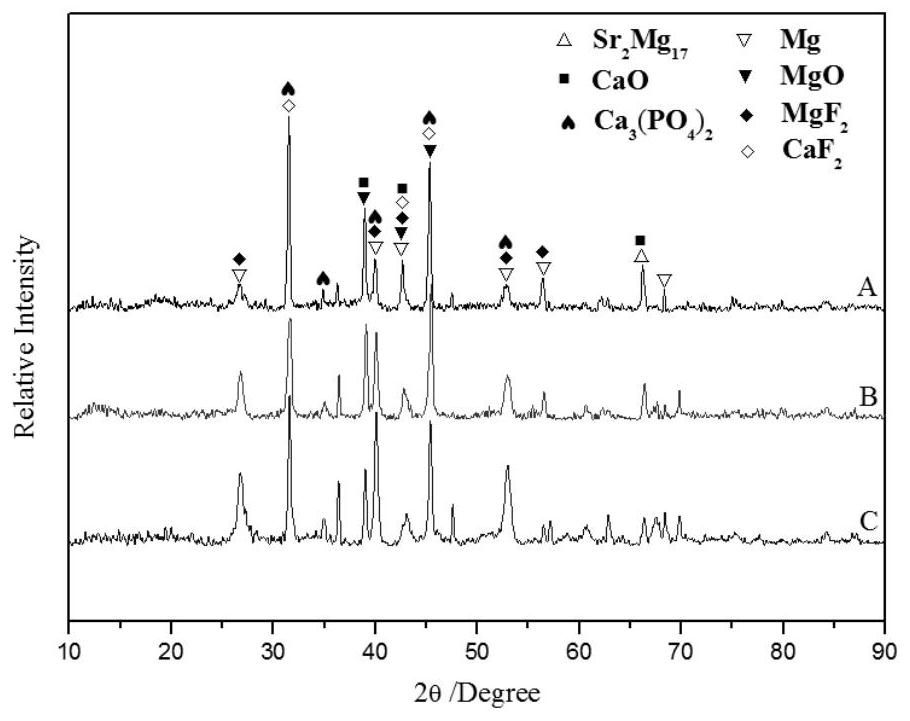

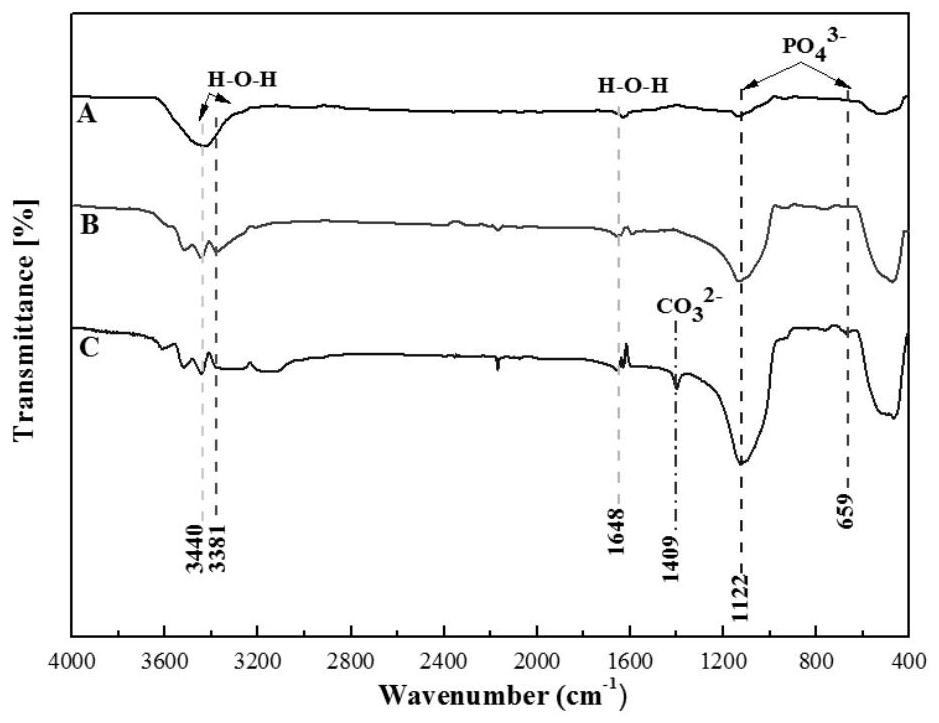

[0098] 3.1 Phase of the film layer

[0099] Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com