Power soil arch model testing system and method based on transparent soil technology

A model test and transparent soil technology, applied in the direction of testing material strength by applying repetitive force/pulsation force, testing material strength by applying stable tension/compression, and measuring devices, etc., can solve the problem of not being able to fully reflect soil deformation, etc. problems, achieve high-precision real-time measurement, and improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

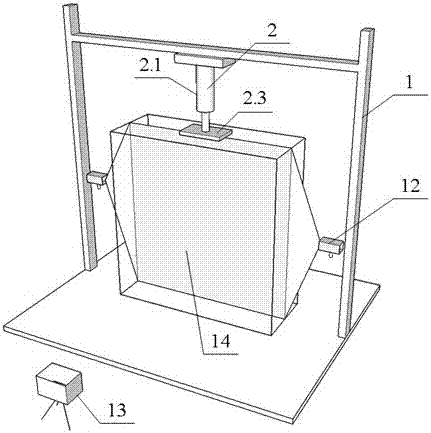

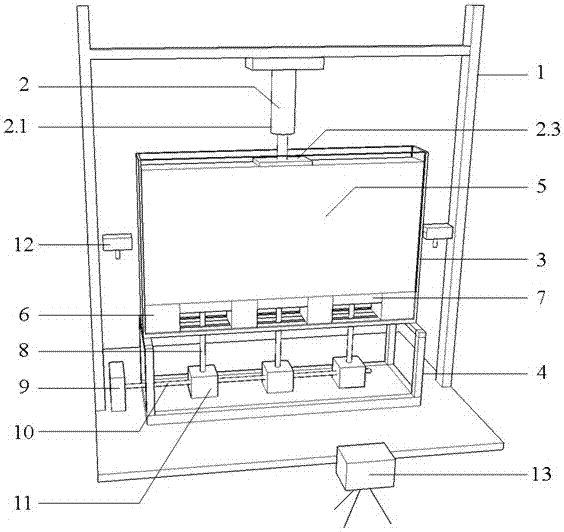

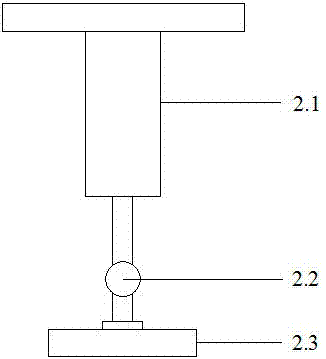

[0043] Example 1: see figure 1 — Figure 8, a dynamic soil arch test system based on transparent soil technology, consisting of loading device 2, model tank 3, transparent soil 5, fixed block 6, movable block 7, worm gear box 11, laser transmitter 12 and high-speed camera 13 and other parts composition. The base of the reaction force frame 1 is anchored on the bottom surface; the model support 4 is placed in the center of the base and fixed; the reaction force beam is adjusted to a suitable height, and the two ends of the reaction force beam are fixed on the column 1.2 with screws; the loading device 2 is fixed on the reaction force Beam center; the model slot 3 is placed on the model support 4, four identical rectangular fixed blocks 6 and three identical rectangular movable blocks 7 are made of transparent plexiglass, the length of the movable block 7 is twice that of the fixed block 6, and the width is equal to The inner width of the model groove 3, the height of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com